The Lake City Army Ammunition Plant, located in Independence, Missouri, recently received recognition from the Secretary of the Army in the form of an Environmental Award for Environmental Restoration.

This recognition is the U.S. Army’s highest honor for outstanding environmental stewardship and leadership, and it is presented to those on the forefront of efforts to protect human health and safety while providing support to warfighting readiness.

“We are extremely proud of the Lake City environmental restoration program and this award clearly recognizes the team for its outstanding past and current efforts,” said Lt. Col. Christopher Denton, LCAAP’s commander.

Production at LCAAP began in 1941. LCAAP provides quality small-caliber munitions to the U.S. Department of Defense, and it is one of more than a dozen subordinate installations under JMC. The command produces, stores, distributes, and demilitarizes conventional munitions for the DoD.

LCAAP understands the need to tackle existing issues with new methods. Using state-of-the-art technology, the Army began an extraction process in early December 2022 at LCAAP. The end goal is to remove trichloroethylene — as a dense non-aqueous phase liquid — from the site at Lake City, which operated as a disposal pit for nearly 20 years and closed in 1979. The thermal heating and extraction process is about 50% complete and is expected to finish by summer of 2023.

Below the ground surface, the silty clay is being heated to 212 degrees Fahrenheit, which will volatilize and migrate the contamination, so it can be extracted from the subsurface quite easily at that state. About 85 days are needed to heat the surface to the desired temperature, which will be held at 212 degrees Fahrenheit for around 60 days or so. At the end of that step, confirmation sampling will begin to verify the contamination is reduced to below cleanup goals, and then at that point the fourth phase starts.

In the final step, the heating system will be turned off and naturally cool while continuing to extract contamination vapors for 15 days.

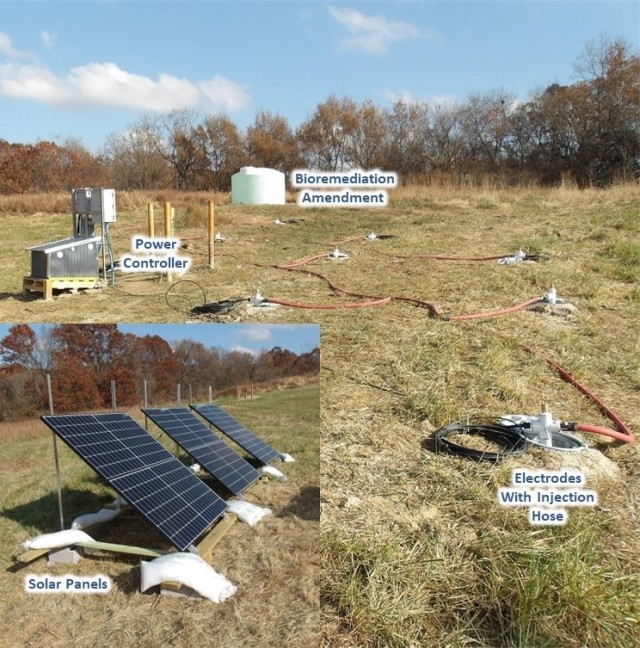

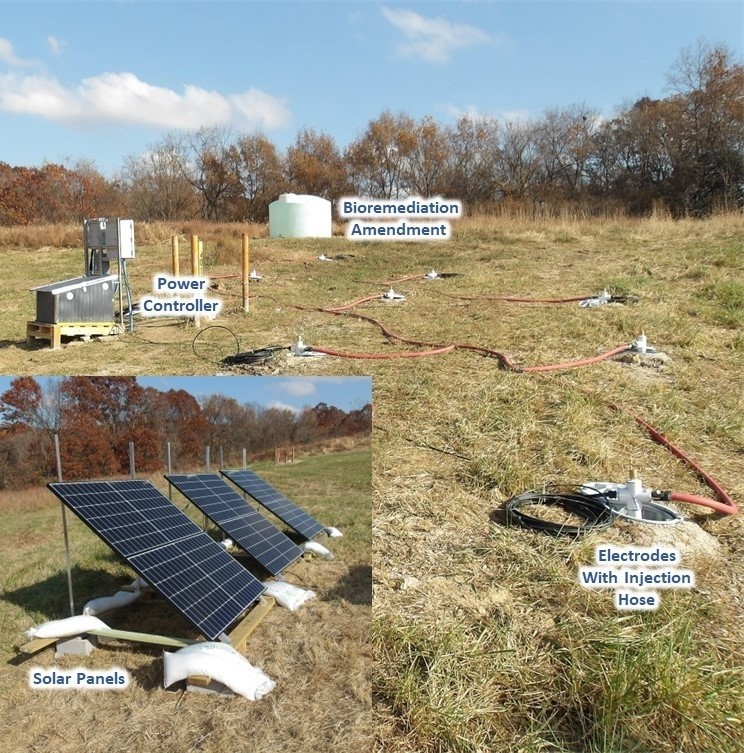

The in situ thermal conduction remediation, or ISTCR, system is not the only project that has taken place at LCAAP as part of its environmental restoration program, which was established in 1980, and it certainly won’t be the last. The LCAAP team also recently completed a green and renewable remediation project using electrokinetic bioremediation. As a green-to-clean system, the project used solar-powered electrodes that extended into the subsurface to degrade explosive contaminated groundwater over 99% to below cleanup criteria.

“The Army and its stakeholders are excited at the positive progress thus far on this project and look forward to what the next few months of field efforts and follow-on data brings to the project and the future of the site,’’ said Sara Clark, the restoration manager at LCAAP. “The health and safety of those in the surrounding community and those who are employed at the installation will remain on the forefront.”

Social Sharing