WASHINGTON – Repurposing, reimagining and recycling are at the core of innovation for re:3D, a small business that is partnering with the U.S. Army to provide novel 3D printing capabilities with an environmental conscience.

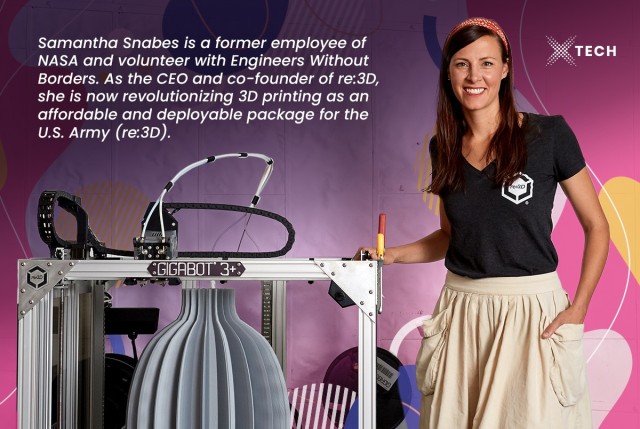

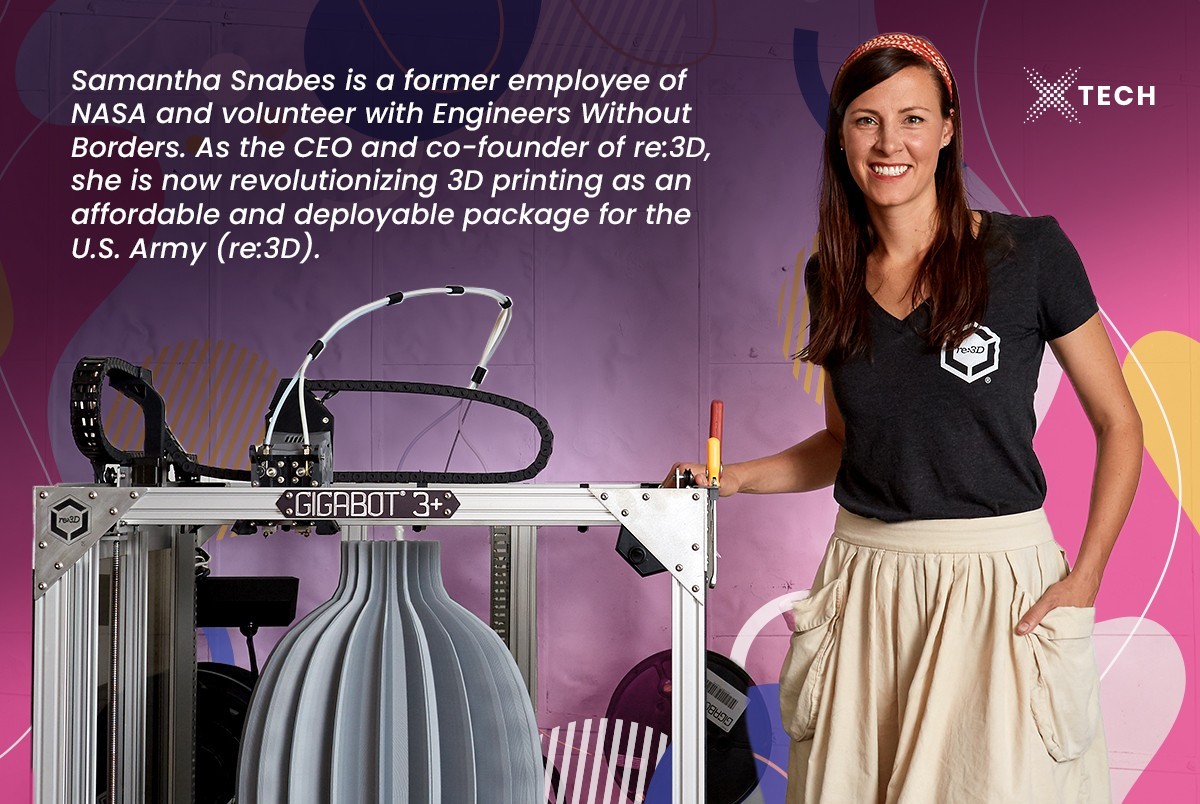

CEO and co-founder Samantha Snabes helped lead efforts to develop the Gigalab, a large-scale 3D printer stored in a climate-controlled shipping container that can be deployed to Soldiers in contested environments for quick printing of functional tools and parts, such as surgical instruments, wrenches and more.

The printer’s pay-off to the Army increases with its clean tech component, which is a unique ability to print these tools using plastic waste that is accumulated on the battlefield. The Gigalab contains all of the materials needed to process waste in preparation for printing, and can operate via wind and solar panels for off-grid energy power. In July 2022, the Gigalab earned re:3D a first-place spot in the U.S. Army xTechSBIR Clean Tech competition, which sought small business technology solutions that could solve Army challenges while also reducing greenhouse gas emissions.

“Whether it’s manufacturing a tool, replacing something that breaks quickly or reusing waste in a better way for supplies that are known to run out, the Gigalab comes in a deployable and affordable package for the Army,” Snabes said.

Snabes’ career, however, did not begin in 3D printing or working with the Army. More than 10 years ago, she was working at NASA and volunteering with Engineers Without Borders. She travelled to areas such as Nicaragua and Rwanda, hoping to help people fabricate goods independently of outside sources. Snabes saw 3D printing as a prime resource to manufacture solutions for real-world problems, so she and her co-founder came up with the idea of a toilet-sized 3D printer that could produce valuable items such as birthing stools, composting toilets and even lower-limb prosthetics.

After shopping the concept around, they won $40,000 through Start-Up Chile to build a prototype and ultimately decided to launch re:3D. After years of working in the commercial space across the globe, Snabes began to explore the dual-use functionality of the Gigalab by applying to the xTechSBIR Clean Tech competition.

“xTech is the Army’s best kept secret,” Snabes said. “The program and the stakeholders we’ve been introduced to have been able to quickly socialize our technology and help us package our solution in a way a that will be really meaningful to the customer in a deployed scenario.”

Snabes and her team walked away as a first-place winner, receiving $12,000 in cash prizes and the opportunity to submit for an Army Small Business Innovation Research contract of up to $250,000. The business is in the early stages of their Army SBIR Phase I award and is deeply involved in materials testing and finalizing the structure of the container to support the Army user. Snabes noted that the Army stakeholders they are working with have been most helpful in pinpointing holes in their logic and helping them come up with the right solutions.

As a female innovator in the field of science and technology, Snabes said that it’s important for women to network and share their ideas so they can do more for the warfighter and national defense.

“The Army is experiencing complex problems, and there should be diversity of thought as these are being solved,” Snabes said.

This diversity can come from a broad range of non-traditional innovators that xTech partners with, including Historically Black Colleges and Universities, international technologists and female industry leaders — with Snabes and re:3D being a prime example of the latter.

Participation in the xTech Program was a major stepping stone for re:3D into the Army ecosystem, and Snabes noted the program’s outreach to diverse, non-traditional innovators is vital to building a robust S&T knowledge base for the Army. The business has big plans to continue developing a solution that keeps their core values of repurposing, reimagining and recycling at the heart of 3D printing.

Established in 2018, the Army xTech Program strives to integrate small businesses and non-traditional vendors into the Army’s science and technology ecosystem by providing opportunities for direct exposure to laboratories, program executive offices and program managers from across the Army. Participants receive detailed feedback from Army and DoD stakeholders and have access to training, mentorship, and other support infrastructure as they progress through the competition to determine how best to align their technology solutions with real users and buyers within the Army.

The xTech Program holds several competitions per year, from open-topic competitions such as xTechSearch, to technology-specific competitions targeting specific Army needs and challenges. For all competition information, go to https://www.xtech.army.mil/.

The Office of the Assistant Secretary of the Army for Acquisition, Logistics and Technology provides the American Soldier with a decisive advantage in any mission by developing, acquiring, fielding and sustaining the world's finest equipment and services, and by leveraging technologies and capabilities to meet current and future Army needs.

Social Sharing