CAMP LEJEUNE, N.C. — Soldiers joined Marines this November to train on additive manufacturing and how to implement it within the DOD at the 2nd Marine Logistics Group Basic Additive Manufacturing Course at the Camp LeJeune Innovation Campus.

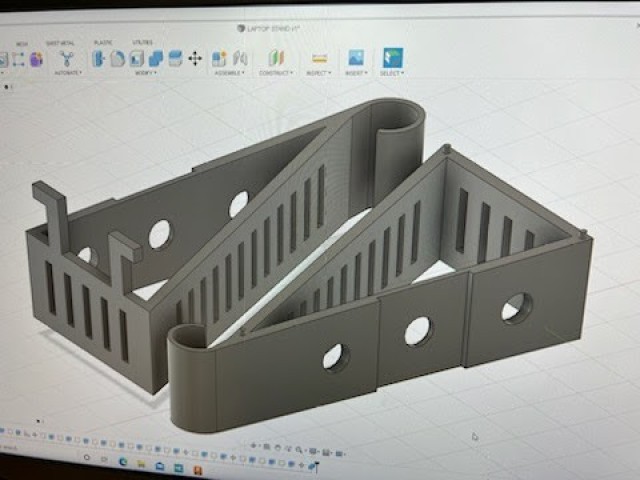

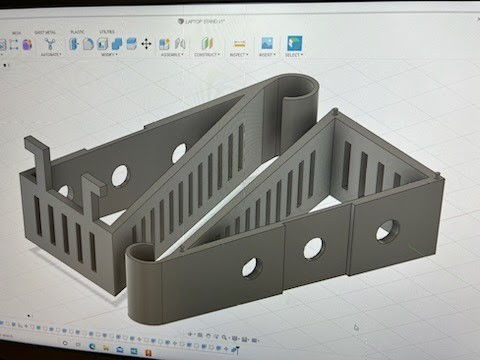

Additive manufacturing refers to a process by which digital 3D designs are used to build a product by depositing successive layers of material.

The Basic Additive Manufacturing Course has been hosted at the Innovation Campus since 2017, teaching Marines concepts including computer-aided design, reverse engineering, design optimization, and 3D printing. This November, however, the course expanded and included three paratroopers from the 82nd Airborne Division — the first Soldiers to attend the course since its inception.

1st Lt. Rob Johnson is one of those paratroopers and serves as the executive officer of "Gainey Company" — the new learning, innovating and teaching organization focused on specific areas where technological expertise would improve the division's lethality.

"[Gainey Company] will involve developing methods for different technologies to work together," Johnson said. "This course helped us learn the tools necessary to build those methods of integration that can be used for the Division to win the next fight."

In addition to the capability of modifying existing technologies, additive manufacturing changes the conversation around supply chain shortages, which currently plague readiness.

"Simple components can deadline a vehicle, causing it (to be) inoperable, and lead times for those components may be months", 1st Lt. Chris Selig, another attendee of the course, said. "Being able to build those components ourselves within the [Airborne Innovation Lab], and teach others is invaluable".

The Airborne Innovation Lab is the newly opened mission-centered makerspace on Fort Bragg. It serves as one of the many initiatives that the XVIII Airborne Corps pursued following the Department of Defense Additive Manufacturing Strategy of January 2021.

"The purpose of this DOD AM strategy is to provide a shared set of guiding principles and a framework for AM technology development and transition to support modernizations and Warfighter readiness within the DOD", the document reads. Beyond improving the lethality and modernization of the Department of Defense, the document outlines how people are still at the heart of additive manufacturing, stating "AM helps us shift the balance toward out greatest strength, the Warfighter".

As both the Camp LeJeune Innovation Campus and the Fort Bragg Airborne Innovation Lab continue to grow, the likeliness of joint AM efforts grows with it.

"Marines and Paratroopers have a very similar problem set," 1st Lt. Jen Sanders, the director of the Airborne Innovation Lab states, "so collaborating on aligned additive manufacturing efforts just makes sense. The Marines bring a certain expertise to the table, and we hope that one day we may host the [2nd Marine Logistics Group] for a course of of the Airborne Innovation Lab".

The Airborne Innovation Lab at Fort Bragg is open to all Soldiers on post, Monday-Friday 1000-1600.

Social Sharing