DETROIT ARSENAL, Mich. – What do the U.S. Army Corps of Engineers and the U.S. Army Tank-automotive and Armaments Command have in common in managing their very different Army missions? In terms of modernization efforts, the answer to that question is: quite a lot.

During a Oct. 25 day trip from Detroit Arsenal to Michigan’s Upper Peninsula and the USACE Soo Locks facility in Sault Ste. Marie, the TACOM commander, arsenal and depot commanders, along with several TACOM staff directors, met with USACE staff to gain differing perspectives and insights into managing and modernizing the more than 150-year-old project.

The historic USACE operated Soo Locks allow navigation from Lake Superior to Lake Huron on a waterway shared by the U.S. and Canada and are one of the busiest set of locks anywhere on the planet with annual traffic numbering in the thousands of ships currently moving more than 80 million tons of cargo. The locks have been improved, upgraded, and replaced over their years of operation and are considered critical infrastructure due to the massive amounts of raw materials transported from Minnesota and Canada to the lower Great Lakes and the Atlantic on ships averaging 700-1,000 feet in length.

“Today was a chance to see how the Corps of Engineers has taken a set of locks built over fifty years ago and is successfully modernizing them,” said Lt. Col. Greg Turner, TACOM’s deputy director for engineering. Turner is also a former commander of the USACE Detroit District covering the Soo Locks Project.

“We’re not focused on the facilities themselves which, in some ways, are very modernized, but (are more focused) on the automation and the people,” he stated.

“The whole purpose is to equip our commanders and other senior leaders to help them sharpen their vision of how they can apply what’s been done here to their own modernization efforts as we work through our 15-year modernization plan.” At the direction of Army Materiel Command and the urging of Congress, TACOM initiated a modernization plan across its organic industrial base of arsenals and depots to ensure the future of the Total Force. That plan is currently in the developmental stage with three main phases planned to guide the next decade and a half.

“Today we heard from the Army Corps engineering team that's been working on modernizing operations for the last ten years and hearing about the lessons they’ve learned,” said Darren Werner, TACOM commanding general. Those lessons, he added, could be directly applied to the TACOM industrial base and included lessons learned in upskilling the Soo Locks workforce, their industrial control network and integration of that network, integrating new technology into their business and understanding how operations have improved as a result.

“Physically being able to see how an organization goes from the industrial age to the digital age while developing their workforce and developing a process to solve challenges is impressive,” Werner said. “They’ve done it, they’ve demonstrated it and they’ve shown us how to get there.”

Werner offered an example:

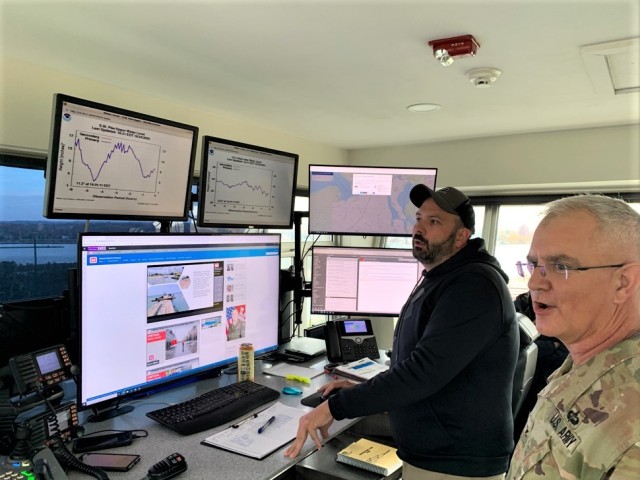

“With their industrial control network, they backed into success. They didn’t realize it at first, but integrating sensors across the Soo Locks into a single network allowed them to apply network technology to their operations. They hired additional people and capitalized on and exploited the technology,” he said, referring to the Soo Locks team’s effort to hire people with the necessary technology-based skills needed to modernize the project and move it into the future.

“We're all really looking at ways that we can modernize our facilities,” stated Col. Shari Bennett, commander of Rock Island Arsenal – Joint Manufacturing Technology Center. “It's good to see other organizations that are dealing with the same challenges, or who dealt with the same challenges that we are dealing with, how they were able to overcome them, and how they came up with different technological advances that maybe we aren't fully aware of yet.”

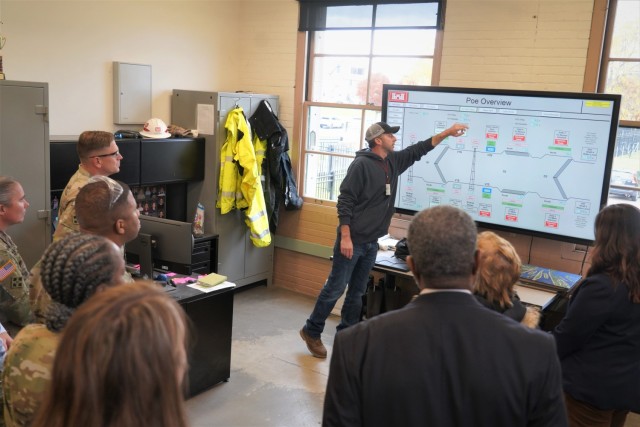

Bennett added that several dashboards and digital displays monitoring various aspects of the locks in real time could be extremely advantageous in managing RIA-JMTC operations.

“This is what we need,” she stated. “In our factory, we want to be able to have a dashboard system setup that my maintenance guys can view to know exactly what machine went down in which building and what the fault is. With that information, we can better know what tools or resources are needed to go out and make repairs.”

Better visibility would also allow her team to make better decisions and utilize the RIA-JMTC workforce and maintainers more efficiently. “They cracked the code,” Bennett said of the USACE Soo Locks team.

“It’s been a great collaboration,” Mary Strum, chief of operations for the USACE Detroit District, said of the day’s tour and discussions. “We have very similar challenges, and talking through best practices – what’s worked and hasn’t worked – allowed a great transfer of information and success stories between our two teams.”

Social Sharing