FORT LEONARD WOOD, Mo. — The U.S. Army Tank-automotive and Armaments Command’s FMX team here took time to promote employee safety by participating in the annual Occupational Safety and Health Administration’s Safe + Sound Week events.

Safe + Sound Week recognizes workplace health and safety programs nationwide each August — this year’s event was held from Aug. 15 through 21.

According to Don Ungerecht, Support Operations manager here, Fort Leonard Wood’s FMX team provides responsive, reliable and uninterrupted field-level maintenance support for a fleet of more than 42,000 pieces of U.S. Army Training and Doctrine Command equipment used in instruction here.

With all of that responsibility — and the potential dangers that work poses — highlighting safety in FMX’s everyday mission is important, Ungerecht said.

“This is an event that we participate in annually,” he said. “There are many hazards that our workforce deals with on a daily basis and having an event like this helps to refocus our efforts on providing a safe environment.”

The week started off with management working alongside employees, performing equipment maintenance, Ungerecht said. The opportunity gave management a firsthand look at the hazards associated with maintenance operations, so better-informed decisions can be made.

Ungerecht said he enjoyed getting reacquainted with what FMX employees deal with daily.

“It’s been quite some time since I was on the shop floor as a mechanic, so doing that gets me back into thinking about what I can do at my level to help them stay safe,” he said. “We maintain a wide variety of military equipment, so our hazards are directly related to equipment maintenance operations. We have lifting, electrical, noise, flying objects, hazardous materials, chemicals and moving vehicles that we deal with on a routine basis.”

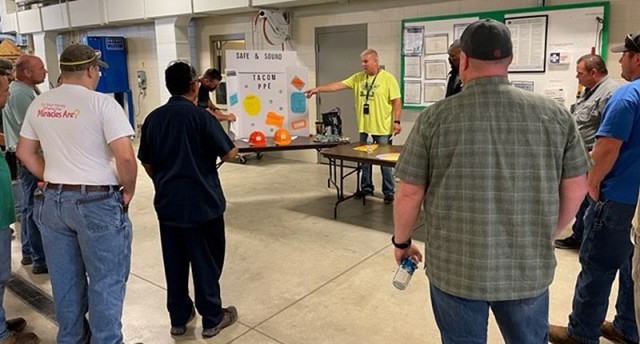

The key to the success of any program is workforce participation, Ungerecht said. In line with that, the team held a safety stand-down day during the week as well. Multiple training events were planned and coordinated by the unit’s employee-led safety council and involved experts from the Army Substance Abuse Program and the Directorate of Emergency Services.

The day included training on topics such as personal protective equipment, weapons safety, ground-guiding techniques, risk identification and reduction, fire prevention, forklift safety, bloodborne pathogen cleanup and response, vehicle battery safety, and a vehicle-hazards display for equipment that is new or uncommon to the organization.

Dave Schiller has been a heavy mobile equipment inspector here for about 15 years. He said bringing awareness to topics during an event like this helps keep employees from getting complacent, which can lead to unsafe workplace habits. In addition, designing it to be interactive and fun makes a safety stand-down day more memorable.

“It’s good team building and a good morale booster, too,” he added. “The guys get a day away from doing their regular job while they learn, and if there are new rules and regulations that come out, it gets that information out to our whole unit at one time, instead of having to have a lot of little classes.”

According to Matt Pankey, an FMX Quality Assurance specialist and safety officer — and one of the key organizers of the week here — OSHA doesn’t mandate Safe + Sound Week.

“It’s just something we do,” he said. “We do it to try to bring the employees in on looking at different areas, looking at all the dangers, to improve our risk-assessment capabilities in the organization and make sure people understand the ‘why’ behind what we do.”

More information on Safe + Sound Week is available on the OSHA website.

Social Sharing