Sometimes, the best solutions come from taking what is on hand, thinking about it in a new way and building something better.

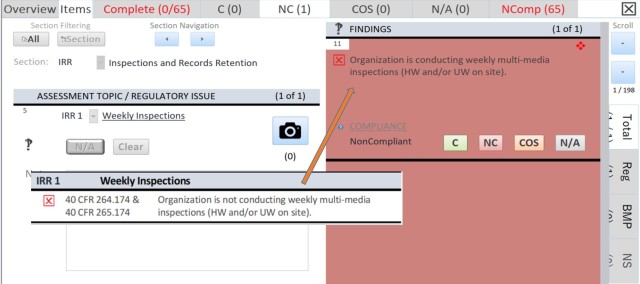

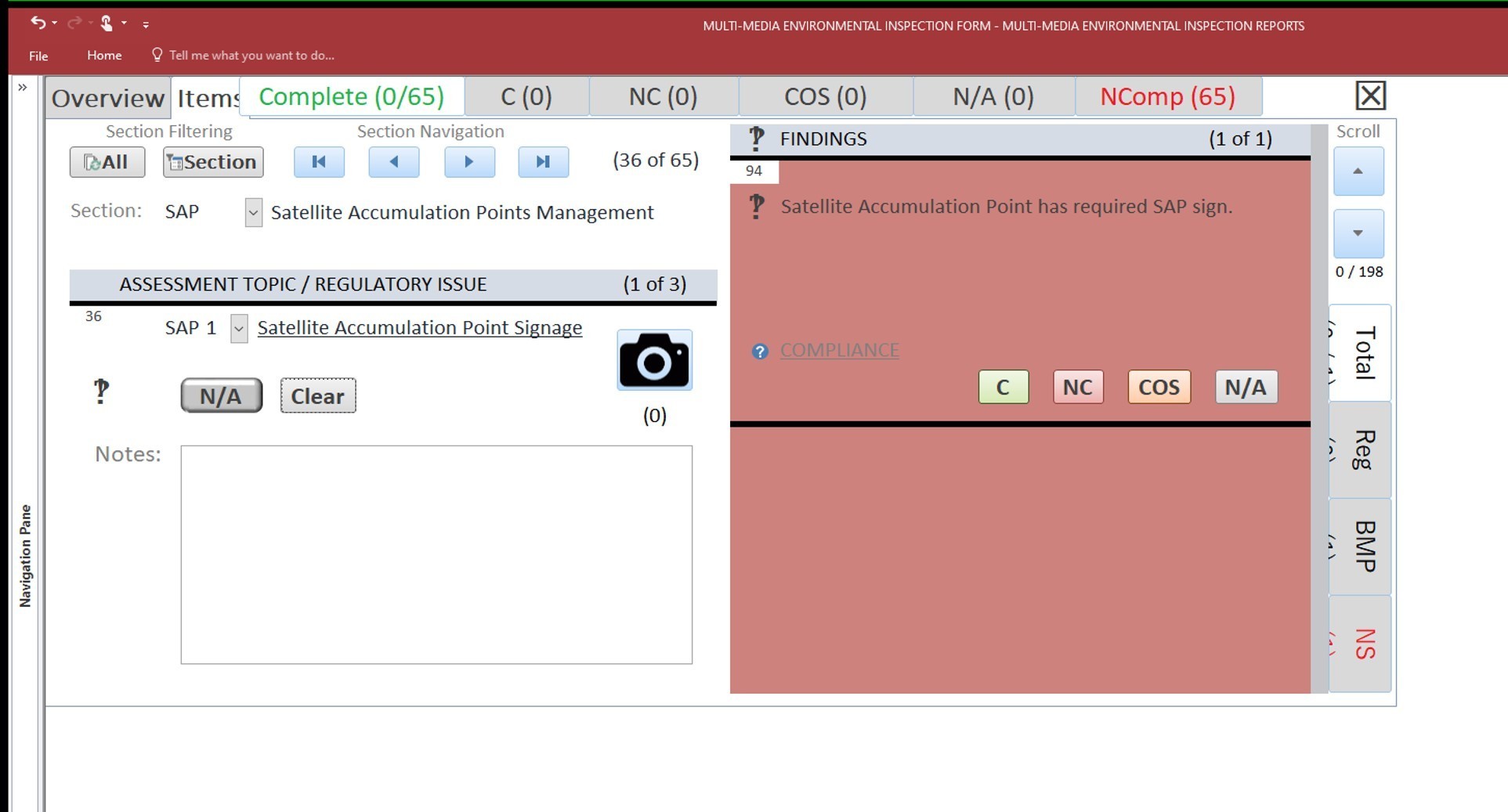

That’s the strategy the team at Fort Riley used in creating the electronic multimedia inspection form and database, a technological way of improving the efficiency and effectiveness of the environmental compliance inspections of its motor pools, hangars and maintenance shops. Through this new inspection system data interface, the Fort Riley team created a valuable new tool to better stay on top of environmental compliance at the installation.

“The multimedia inspection form and database we created uses standard Army-issued software products, which means we avoid the complicated data transfer process required if we were to use private-sector providers, and also avoids the use of proprietary software, which also comes at a cost,” said Kyle Kirchner, pollution prevention branch chief.

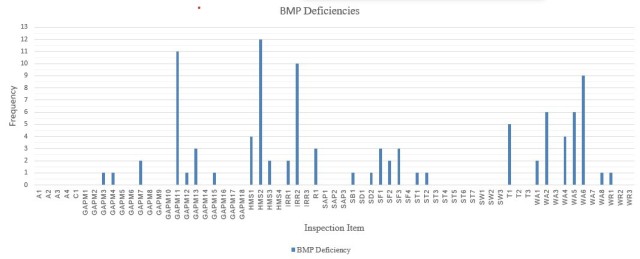

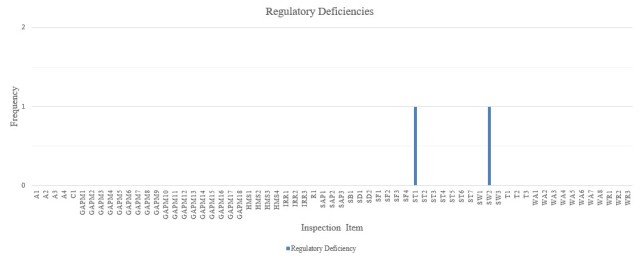

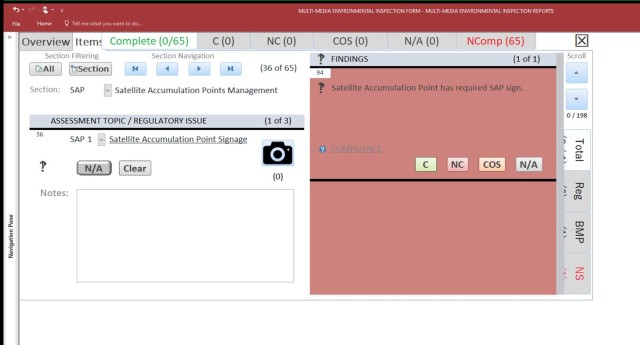

The system operates on a three-tiered rating system, ranging from green to amber to red, using information collected during inspections.

“The inspection form automatically tallies regulatory and/or best management practice deficiencies discovered during the inspection to assign the rating,” Kirchner said.

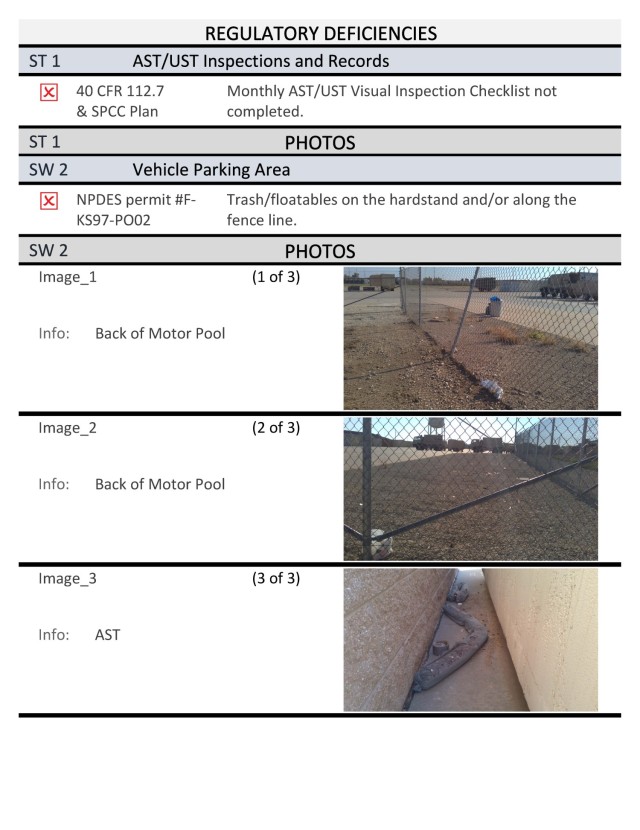

A summary report is shared with the organization’s leadership when a red rating is issued and a complete report is issued to the organization’s environmental team to engage them and assist in addressing any deficiencies discovered.

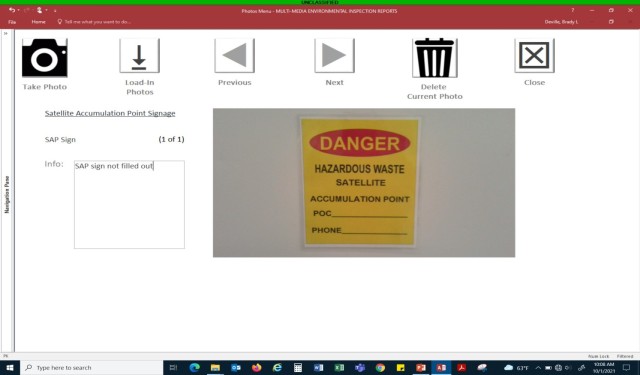

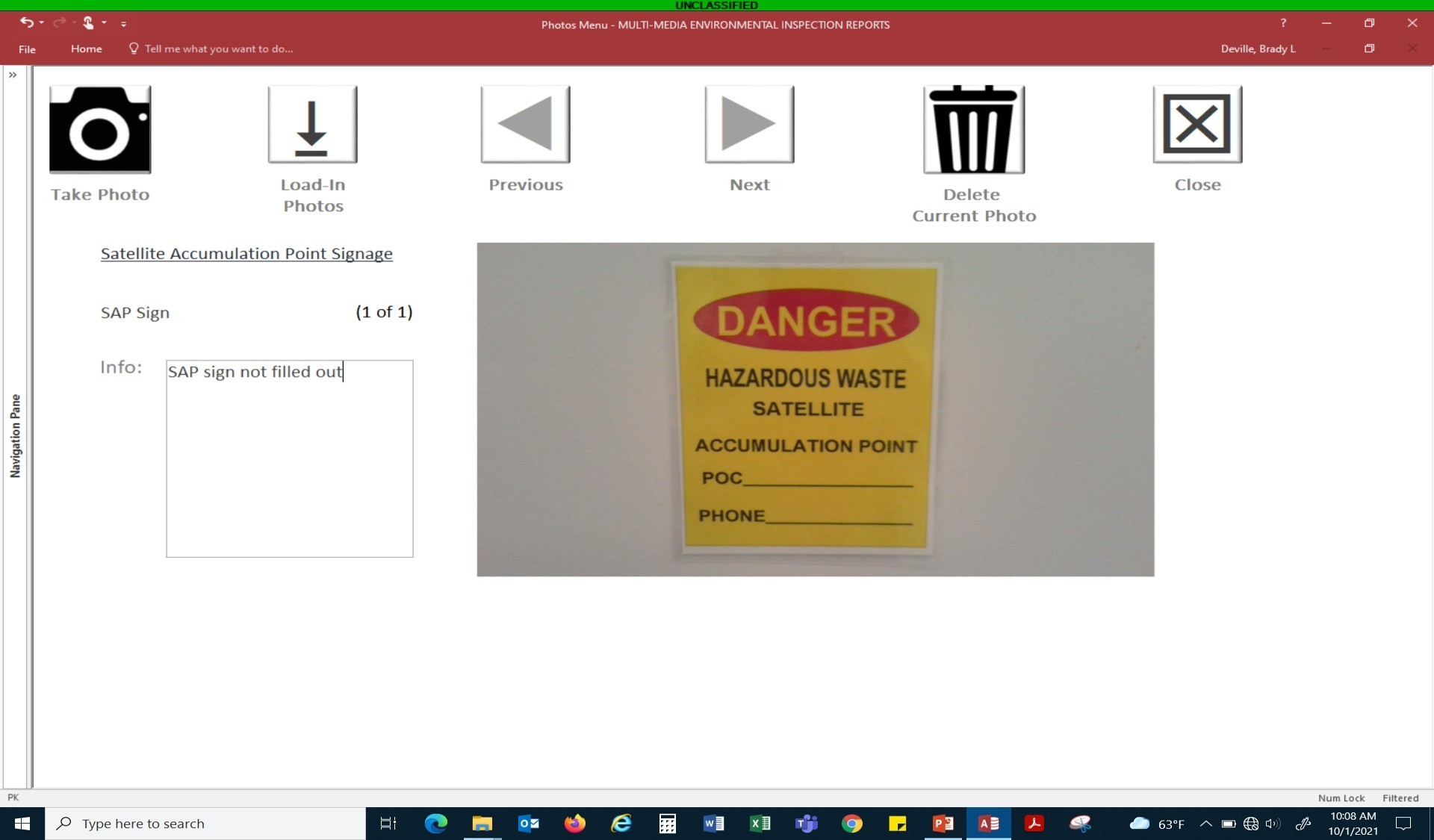

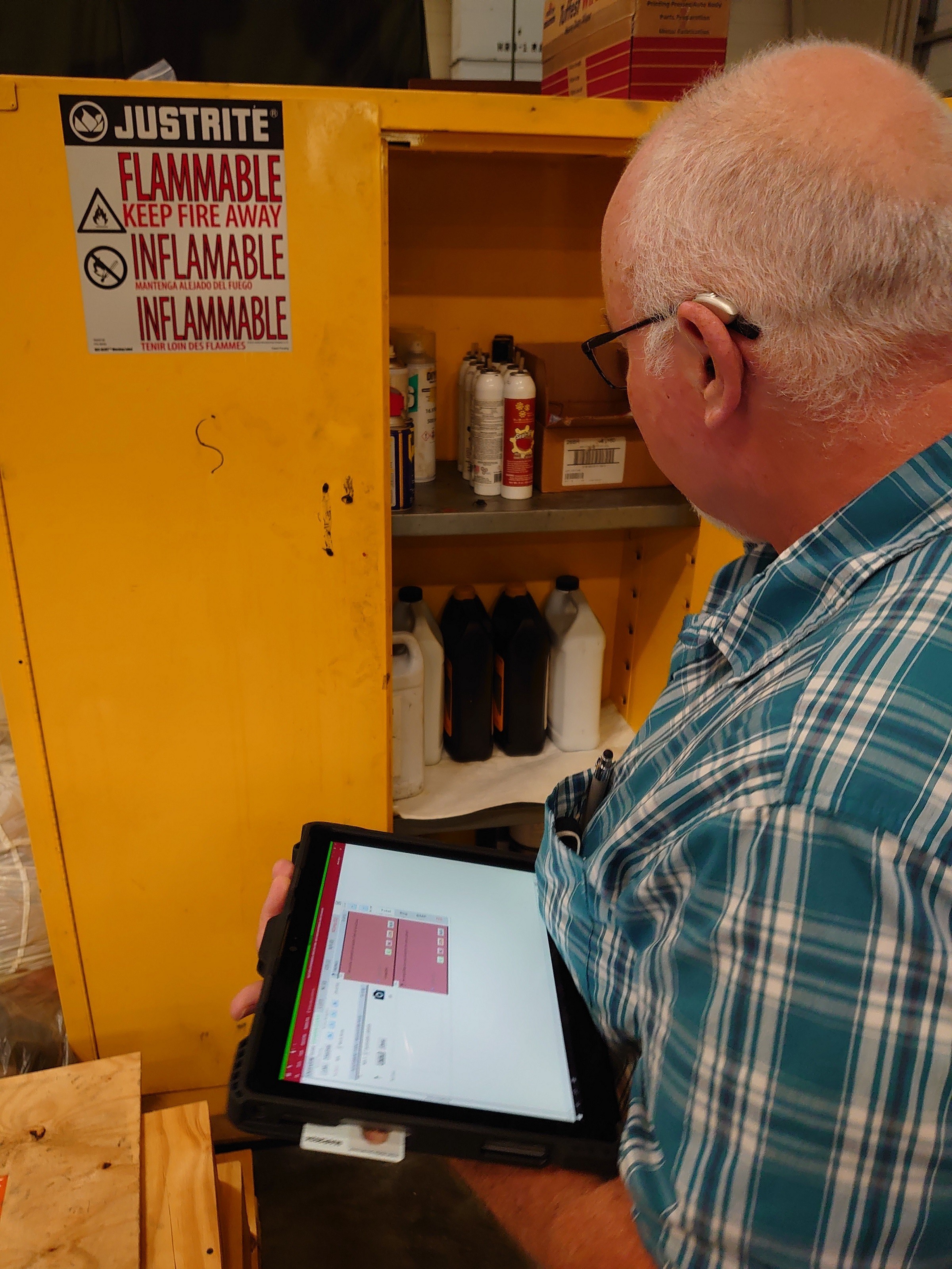

The new inspection forms and the use of standard tablets to compile the data in the field, including photography, makes submitting photos easier than past processes, and makes the inspection reports more useful in solving problems according to Brady Deville, environmental compliance inspector.

“The value in the automatically generated reports, incorporating photographs of noted compliance concerns, for the organization’s environmental team leader and members is a specific visual depiction of the environmental concern that the organization can use for future reference and to communicate with the organization’s line personnel to improve their practices, limiting potential regulatory findings in the event of a state or federal inspection,” said Deville.

Another benefit of the new system is it allows tracking of the installation compliance posture by individual organizations, which improves tracking and helps identify areas of future training through analysis of the report data.

“We are able to use the data we collect to determine the areas where training will be most effective and important, replacing the ‘gut feel’ approach or even the ‘existing training material/presentation is good enough’ approach,” Kirchner said. “This gives us a greater understanding of the issues at hand.”

The multimedia inspection form and database are also being applied to the management of storm water on the installation, and for conducting construction and industrial storm water inspections.

Social Sharing