CAMP HENRY, South Korea – The Logistics Readiness Center-Honshu provides maintenance, supply, transportation, and logistical support to installation partner units, and Department of Defense activities to ensure mission readiness and quality of life for Soldiers, civilian employees, and family members on mainland Japan.

LRC-Honshu is headquartered at Camp Zama, Japan, in the cities of Zama and Sagamihara in Kanagawa Prefecture, about 25 miles southwest of Tokyo on the island of Honshu.

Camp Zama is home to U.S. Army Japan, I Corps (Forward), U.S. Army Aviation Battalion Japan, 311th Military Intelligence Battalion, Japan Engineer District, U.S. Army Corps of Engineers, 78th Signal Battalion, and the Bilateral Coordination Department and 4th Engineer Group of the Japan Ground Self-Defense Force.

LRC-Honshu reports to the 403rd Army Field Support Brigade, headquartered at Camp Henry, South Korea, which a subordinate unit aligned under the U.S. Army Sustainment Command located at Rock Island Arsenal, Illinois. ASC falls under U.S. Army Materiel Command, headquartered at Redstone Arsenal, Alabama.

LRC directors are dual-hatted. They lead their respective LRC, while serving as the garrison commander’s senior logistician by advising, assisting, and representing the organization on all maintenance, supply, and transportation matters.

The LRC-Honshu Director, Sean Mager, also serves as the 403rd AFSB commander’s senior logistician in Japan.

“I’m honored to lead an organization that is responsible for providing world-class logistical installation services and support to Soldiers in a transforming theater,” Mager said. “Every day presents a new set of challenges, but they’re challenges I live for. The most satisfying aspect of my job is the opportunity to work with a professional group of Department of the Army civilians and local national employees to support USARJ Soldiers in the ‘Land of the Rising Sun.’”

LRC-Honshu provides a broad and complex array of essential services and support, from hosting the annual Thanksgiving meal at the Camp Zama Warrior Restaurant, to maintaining vehicles and equipment.

“From soup to nuts, we provide all types of logistics support to garrison and tenant units on Japan’s largest island,” Mager said.

USARJ is not structured as a conventional command, but rather is resourced as an economy of force operation, forward positioned in Japan for contingency purposes should circumstances require a larger U.S. Army presence within the region. Because of this, USARJ relies on the 403rd AFSB to operate activities and perform services that USARJ units are not internally equipped to perform. Any work above approved baseline services are performed on a reimbursable basis with established support agreements.

Under the Security Forces Agreement, the Government of Japan contributes a portion of the resources necessary for the sustainment of U.S. Forces within Japan in the form of facilities, personnel, and utilities. ASC benefits from this agreement in the form of significantly reduced operating costs. LRC-Honshu’s workforce primarily consists of Master Labor Contract employees funded by Japan.

The LRC-Honshu Supply and Services Division’s Property Book Office provides logistics support and accountability of supplies and equipment, while the Installation Supply Support Activity provides class II, III (P), IV, VII, and IX supply support and secondary items support to USARJ. The Fuel Management Section provides fuel to customers, while maintaining safe operational conditions at the fuel stations. The Hazardous Material Control Center receives, stores and issues hazardous and toxic materials and substances for installation partners.

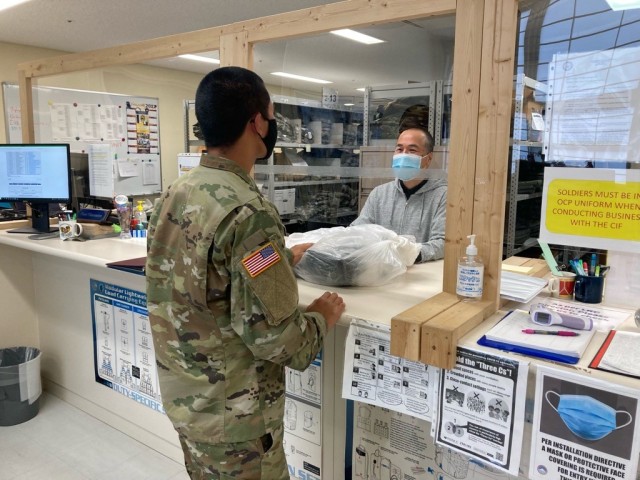

The Central Issue Facility provides Organizational Clothing and Individual Equipment Facility support. The Laundry and Dry Cleaning Plant, located on Sagami General Depot, provides quality laundry service and support for retail and organizational customers with turn-in points located at Camp Zama, Sagamihara General Depot, and Yokota Air Base.

The Transportation Division’s Transportation Motor Pool provides ground transportation support for official and administrative requirements in support of USARJ and tenant units and supports Department of Defense Education Activity schools with drivers for student transportation requirements.

The Area Transportation Offices at Camp Zama and Kure Pier 6, (477 miles from Camp Zama, near Hiroshima), provide area-specific installation transportation, traffic management (passenger, freight, and personal property movements) for the Camp Zama community, Sagami General Depot, Yokota Army Aerial Port Liaison Office, Kure, and the rest of the geographical area of responsibility.

The Unit Movement Branch provides guidance, assistance, instruction and monitoring for deployment planning and execution processes, while the Transportation Equipment/Engineering Branch manages and accounts for Army transportation equipment, by programming, allocating, distributing, and providing disposition for non-tactical vehicles, materiel handling equipment, administrative watercraft, and containers; and develops and submits replacement requirements.

The LRC-Honshu Maintenance Division provides Base Operations support to Army-owned non-tactical vehicles, tactical vehicles and non-standard equipment, in support of installation services, as well as organic maintenance capability for unit’s tactical equipment lacking organic authorizations.

Recently, the Automotive-Mechanical Equipment Branch overhauled 22 Inland Petroleum Distribution System 800 gallons-per-minute pumps from Army Prepositioned Stocks-4 under the Fiscal Year 2021 Service Life Extension Program. The 800 GMP pumps, which serve as the mainline pump in the IPDS Pump Stations, were originally built during the late 1980s. Many were approaching 30 years of service and experiencing mechanical failures because of aging parts and electronic components associated with the pumps Cummings engine power pack.

The U.S. Army Tank-automotive and Armaments Command codified authority to allow LRC-Honshu under the Service Life Extension Program to leverage TACOM for parts from Sierra Army Depot in order to replace the current power pack and control panel with a new Caterpillar C15 Industrial Diesel Engine-based power pack currently used in the Army’s Palletized Load System truck fleet.

“The work we performed on the IPDS pumps extended the life of the critical pumps, increased readiness, and saved the Army approximately $1.5 million in labor and transportation costs,” said Michael J. Moore, Maintenance Division chief.

The LRC-Honshu Allied Trades Branch provides automotive body work, painting, metalworking, welding, machining, carpentry, and canvas/sewing support. The Armament Branch provides subject matter expertise in testing, inspection, adjustment, alignment, calibration, removal/installation, and repair of various small arms to ensure unit readiness. The Communications and Electronic (C&E) Branch promotes excellence in the field of electronics and specializes in communications-electronics systems and office electronic equipment, to include installing, maintaining, troubleshooting, overhauling, preventive maintenance services, and repairs.

LRC-Honshu provides transportation, laundry services, and support of operational ration orders for USARJ exercises. During Japan’s largest bilateral exercise, Yama Sakura 81, LRC-Honshu assisted with operational ration orders, downloaded, stored, and shipped off bulk perishable and semi-perishable subsistence items for provided non-tactical vehicle support for distinguished visitors, driver support to USARJ Protocol, Class C vehicles, and numerous airport shuttle runs, including missions to Haneda and Narita International Airports supporting. LRC-Honshu also laundered items for Soldiers participating in the exercise.

“This bilateral partnership between the United States and Japan remains a top priority,” said Michael Odom, Plans and Operations Division chief. “We demonstrated our commitment to strengthening bilateral relationships while supporting the security interests of our allies in the region.”

In addition to the wide-range of responsibilities and support provided, LRC-Honshu remains nested with USARJ G4 (Logistics) on all logistical support requirements, while advancing the 403rd AFSB’s role in theater, as both organizations work cohesively to align personnel, resources, and mission sets.

USARJ facilitates multilateral cooperation with regional partners and allies through engagements, training, and exercises; partnering with the JGSDF to enhance interoperability, capability and capacity while coordinating through United States Forces Japan for forces, footprints and agreements between the U.S. Government and the Government of Japan to set conditions for successful deterrence and execution of contingency operations.

Social Sharing