Effectively managing two community drinking water systems, implementing a collaborative multi-unit surveillance strategy to ensure water quality, while simultaneously building strong community relationships has earned the Fort Stewart-Hunter Army Airfield (FSGA-HAAF) Water Quality (WQ) Team a 2022 Secretary of the Army Environmental Award.

“Our WQ Team has focused on developing better efficiencies and connecting formerly stove-piped operations into a cohesive group that helps us meet all Army, state and federal drinking water standards,” Col. Manuel Ramirez, FSGA-HAAF garrison commander, said. “We’re dedicated to protecting the installation’s community while collaboratively developing creative solutions to ensure we maintain military training capabilities and critical support functions.”

One project that demonstrated the flexibility and innovation of the WQ Team was the replacement of an aging water storage tank. Rather than simply replacing the tank in kind, a collaborative assessment of requirements by the WQ Team resulted in a much better solution. The end result, two smaller tanks were installed – one for potable water, the other for fire suppression – improving both water quality and overall safety.

Removing stovepipes and expanding participation added an important cultural shift that helped lead to collective success of the team. By adopting a “See Something – Say Something” approach to water system operations and quality monitoring, all FSGA-HAAF affiliated agencies and personnel are empowered to participate as part of the shared mission of serving the community.

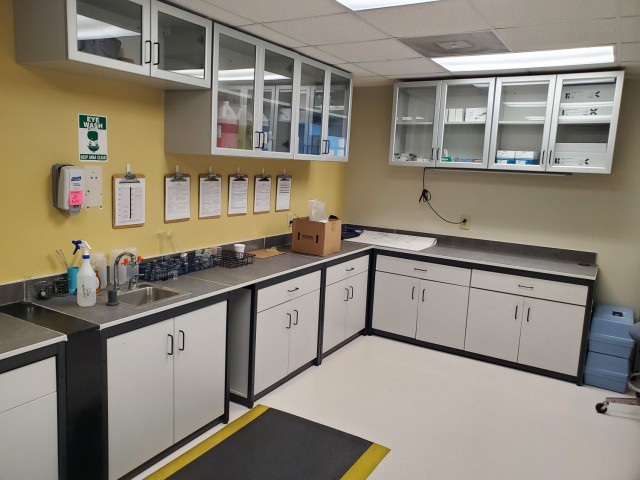

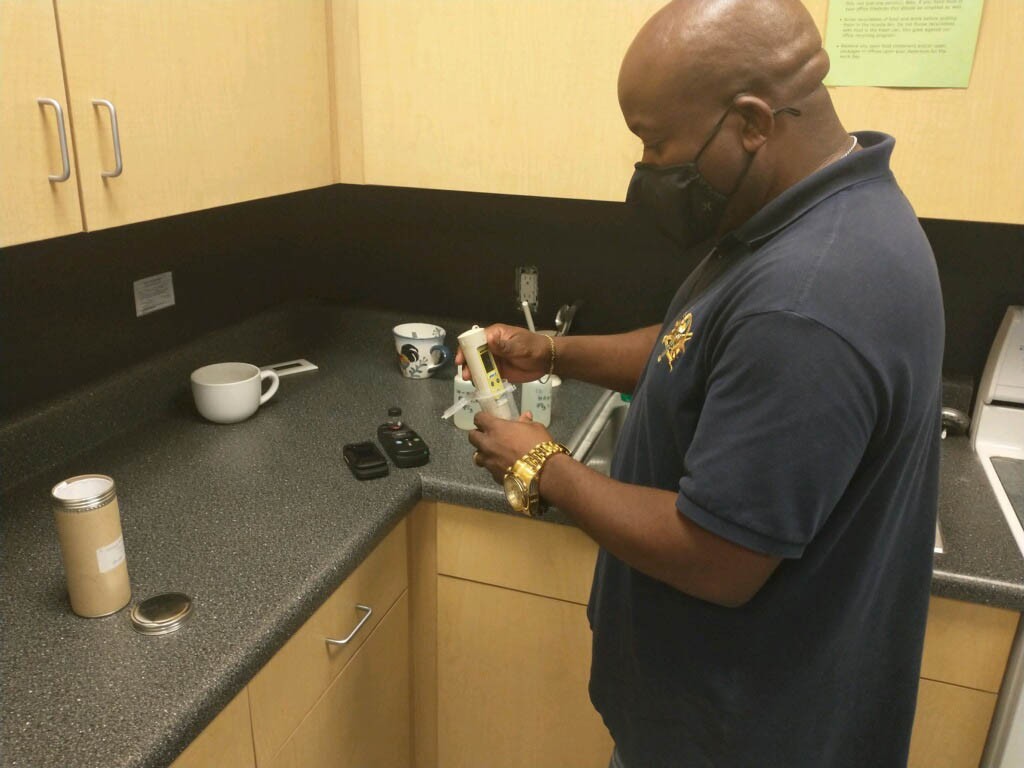

Another important improvement by the WQ Team was the establishment of a joint responsibility and accountability sampling protocol, which has allowed the installation to avoid repeat sampling and unnecessary public notifications due to sampling errors. As a result, the WQ Team has been lauded for its attention to effective regular monitoring to ensure full compliance with Georgia State regulations – collecting 40 bacteriological samples each month from the community systems and 12 samples each quarter from the non-community systems. To further improve water quality, an effective flushing program was implemented, and to improve efficient and timely response to emergencies, FSGA-HAAF has its own state-certified surveillance laboratory.

A vital component of the WQ Team’s success has been an extensive outreach program, which includes multiple briefings, committee meetings, community water forums as well as feedback sessions, roundtables and more. FSGA-HAAF Environmental Division Chief Thomas Fry said that bringing “the best science available” to these partnership sessions between federal and state agencies, universities, research institutions and non-governmental organizations, as well as U.S. Army experts, helps bolster public confidence.

The Annual Consumer Confidence Report (also known as the WQ Report) is an example of some of FSGA-HAAF’s outreach efforts. The WQ Team developed its easy-to-read report in a manner to best support transparency to their water patrons. The format of this report was commended by the Georgia Rural Water Association as being “well-organized, and visually appealing – allowing for easy interpretation.”

“Water quality is extremely important to our team, and the public knows it,” FSGA-HAAF Director of Public Works James Heidle said. “We’ve built on existing relationships, involved experts from multiple agencies and organizations, improved our processes and really set the groundwork for a highly effective WQ Team.”

Social Sharing