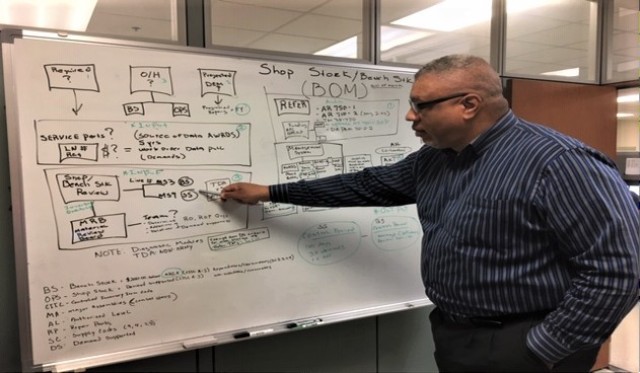

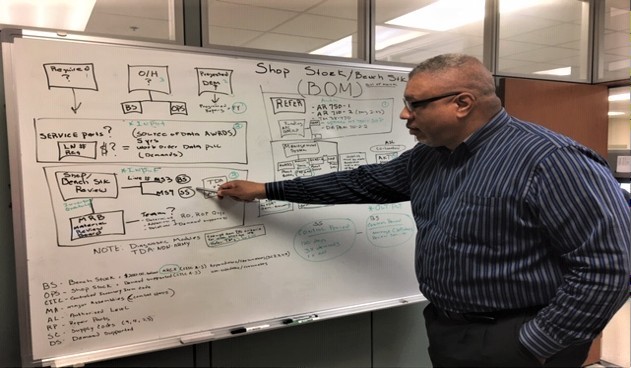

Darren Ratcliff serves as the Army Field Support Battalion – Northeast Asia Maintenance Division Chief. His analysis and restructuring of major repair parts or material (CL-IX) Shop Stock requirements in Shop Supply Operations resulted in the establishment of more than 2,805 Bill of Materials Service Kits for more than 132 major end items utilizing existing parts and refinement of select stocks that best support the requirements, resulting in average cost of service materials reduction from $4,000 to just under $1,500 per, resulting in potential cost savings of more than $330,000 over the next four years. The project increased cumulative productivity and enhanced customer wait time by more than 25 percent.

Overall Shop Stock re-alignment efforts also resulted in receiving the turn-in credit of more than $4.7 million and reducing the Shop Stock lines from 2,500 lines to 1,257 lines by aligning the stocks to true requirements. This will result in more cost savings over time. As a result, AFSBn-NEA was able to return $3.4 million back to the U.S. Army Sustainment Command.

Mr. Ratcliff also led the Army War Reserve Deployment System (AWRDS) to Global Combat Support System-Army (GCSS-Army) conversion, providing expert knowledge and advice to the AFSBn-NEA team. He played a critical role during the AWRDS to GCSS-Army conversion as an active trainer and subject matter expert, carefully coordinating and executing myriad tasks associated with the conversion. His efforts resulted in a seamless transition from AWRDS to GCSS-Army to include the training requirements for the Department of the Army Civilians and Local Nationals, Post Go Live activities, and continuous coordination with battalion staff, the 403d Army Field Support Brigade, the ASC Enterprise Logistics Systems Division, and the GCSS-Army Project Manager. His efforts resulted in a successful conversion with 100 percent completion of all associated task and on time.

Please meet Darren Ratcliff …

Hometown: New Orleans, Louisiana

How long have you been working for the U.S. Army?

My total service time spread over a period of 39 years.

What other positions have you held with the U.S. Military?

My career spans across many positions from Heavy Track Vehicle Mechanic, to Senior Enlisted Advisor to the Battalion Commander. My civilian career service includes the Director of Support Operations, 21st Theater Sustainment Command-Europe, followed by a period as the Director of Production Assurance at Letter Kenny Army Depot, Pennsylvania. I am currently assigned as the Chief of Maintenance Division, AFSBn-NEA, Army Prepositioned Stocks-4 Korea.

Tell us about your job and what you do:

I oversee the maintenance program within the APS-4 footprint. Enforce standards in accordance with Army Regulation 750-1 Army Maintenance Operations and Procedures, working through the staff and subordinates. I supervise the organization and efficiency of reports to include significant changes, requirements and mission capable status to the commander and am accountable for all applicable information regarding field and sustainment level maintenance repairs.

How long have you been in this position?

AFSBn-NEA on boarded me into the position 14 months ago.

What other duties are you responsible for?

I keep account of projected maintenance personnel gains and losses for our workforce including Department of the Army civilians, contractors, Korean National employees. I oversee the execution of required repair parts funding ($2.8 million) based on part status from the Equipment Status Report. I coordinate and execute a weekly maintenance meeting to provide our Supported Organizations with updates to status of equipment on the Equipment Status Report. I also create a daily readiness status of critical combat systems using operational readiness data from the Equipment Status Report provided by Global Combat Support System-Army (GCSS-Army).

What are some of your accomplishments while at AFSBn-NEA?

I led the Battalion Maintenance Team, battalion staff, and other key managers in completing multiple projects resulting in more cost-efficient APS-4 operations. Improvements include less maintenance matrix reports, a new equipment surveillance plan, and the reestablishment and refinement of Shop Supply operations that resulted in cost savings of over $3 million, allowing AFSBn-NEA to return over $2 million dollars to Army Sustainment Command so the funds could be efficiently redistributed throughout the command. My focus and emphasis on proper Care of Supply in Storage (COSIS) operations and safety has resulted in zero recordable accidents and a safer work environment despite multitude of potential safety hazards associated with maintenance operations. We have sustained an average Operational Readiness rate of over 98 percent, achieved 100 percent completion of cyclic maintenance and exercise programs for Fiscal Years 2020 and 2021, achieved steady progress on projected completion of FY20-21 workload, and reduced overtime hours by 95 percent, which equates to over $180,000 in cost savings/avoidance.

Tell us more about the Army War Reserve Deployment System (AWRDS) to Global Combat Support System-Army (GCSS-Army) conversion. What was your role?

My tasks were to plan and alleviate challenges, by evaluating common functionalities between Army War Reserve Deployment System (AWRDS) current processes and GCSS-Army while working with Program Manager programmers in developing GCSS-Army process that would fit COSIS planning for sustainment purposes. I developed the educational strategy early in the implementation process. Lead the development of the Division’s Training Resource Center where we were able to incorporated GCSS-Army training via web-based training.

How will the migration benefit the Army?

GCSS-Army does more than replace the functionality of current systems; it also eliminates some unnecessary processes. New processes are introduced, which can lead to substantial benefits across Army Sustainment to improve Army readiness. None of these benefits can be realized if leaders fail to overcome implementation challenges. AFSBn-NEA will no longer be behind the curve or exposed to potential security flaws due to outdated operational applications. Constant change and innovation success stresses providing real time support to the customer which is priority number one. The GCSS-Army Enterprise allows APS the same tools the customers is accustomed to. Transition from legacy applications is a huge change.

What is the best thing about working at AFSBn-NEA?

Simply put, the workforce, people, and individuals within. The level of expertise professionalism on constant display is amazing.

What do you like to do in your free time?

Working on small craft projects and developing my woodworking skills.

Social Sharing