CAMP CARROLL, Republic of Korea — U.S. Army Medical Materiel Center-Korea teams are leveraging automation technology to increase efficiency and reduce staff burden in the center’s distribution warehouse.

“We just installed a cross-docking robotic system, similar to (large online retailers),” USAMMC-K Commander Lt. Col. Marcus D. Perkins said. “This helps us meet our scalable workforce requirements across the entire conflict continuum to support Multi-Domain Operations.”

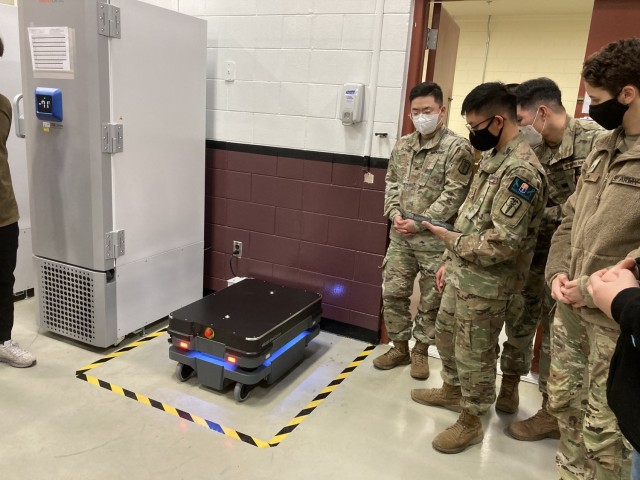

Launched as a pilot program in December 2021, USAMMC-K installed a robotic carrier system the goal of reducing manpower requirements to deliver processed medical supplies from the warehouse’s receiving section to storage and shipping sections as workers fulfill customer requests.

“This equipment will allow personnel from the receiving section to continue to process supplies with no interruption of delivering to two different sections,” said Master Sgt. Rizmel Paguio, non-commissioned officer in charge at USAMMC-K’s distribution center. “It has helped increase production and reduce turnaround time in processing Class VIII supply requests.”

The system operates with the use of a tablet, which routes the delivery vehicle throughout the warehouse. Once it routes the orders, it can autonomously return itself back to its charging station.

In just a few weeks of operation, the system has helped the workforce further understand the importance of integrating new technology into USAMMC-K’s operations.

“Since USAMMC-K is a business enterprise, we need to be able to match the capabilities of other companies to provide the same quality and effectiveness of service, especially in support of our warfighters during a transition to hostilities situation,” Paguio said.

Paguio said the added productivity in processing orders enables team members to focus on their work without having to leave their area to manually push supplies to other sections.

Additionally, USAMMC-K is in the process of replacing some of its standard shelving with an automated vertical shelving system, which Paguio said will further improve productivity and reduce spatial requirements.

USAMMC-K, a direct reporting unit to Army Medical Logistics Command, serves as the theater lead agent for medical materiel, or TLAMM, for U.S. Forces Korea and provides medical materiel support to theater medical forces. The center also ensures tactical units are integrated into the medical supply chain and assists combatant commanders in health logistics support planning.

“These projects are part of USAMMC-K’s initiative and vision of being the premier TLAMM in the Department of Defense,” Paguio said.

Social Sharing