Photos and Story by: Sgt. Melissa N. Lessard, 504th Expeditionary Military Intelligence Brigade Public Affairs

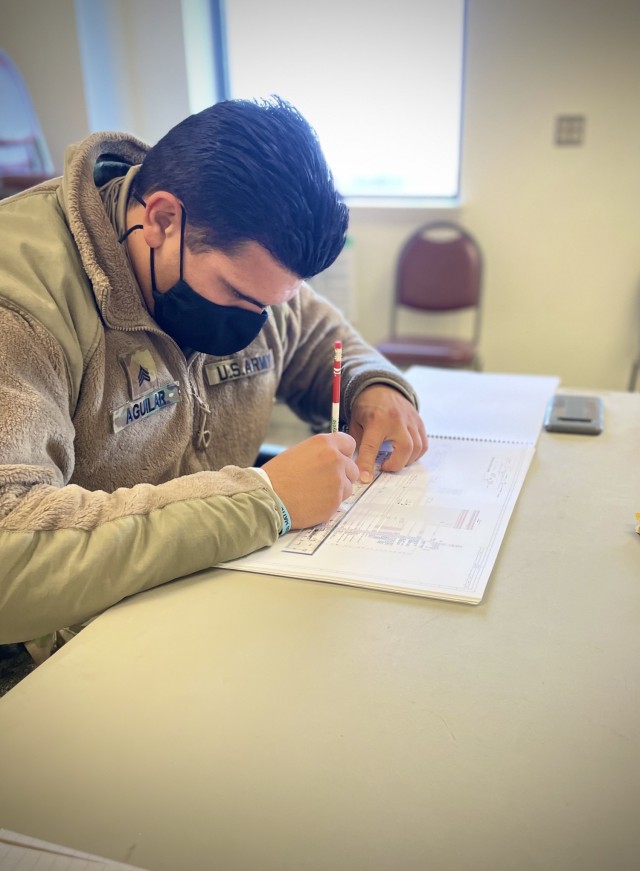

(Fort Hood, Texas, Dec. 3, 2021)--Mechanics with the 504th Expeditionary Military Intelligence Brigade attended manufacture specific Mine-Resistant Ambush Protected All-Terrain Vehicle troubleshooting training Nov. 29 through Dec. 3 here.

The brigade brought out an expert from the manufacturing company to give these Soldiers an in depth training to better their understanding of equipment breakdown and reduce maintenance costs.

“When it comes down to the vehicle maintenance the training speeds up troubleshooting tasks and saves money for the force,” said James Compton, a product training specialist.

Compton served in the Army for 8 years before becoming an instructor for a manufacture. He teaches around 10-15 classes a year; not only to all branches of the military, but to civilian and international workers as well.

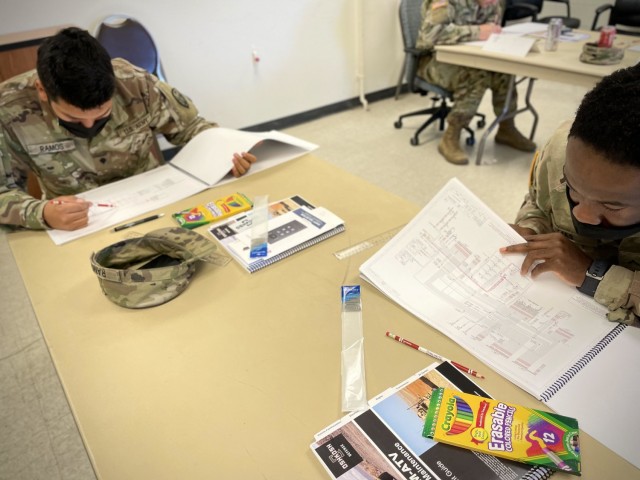

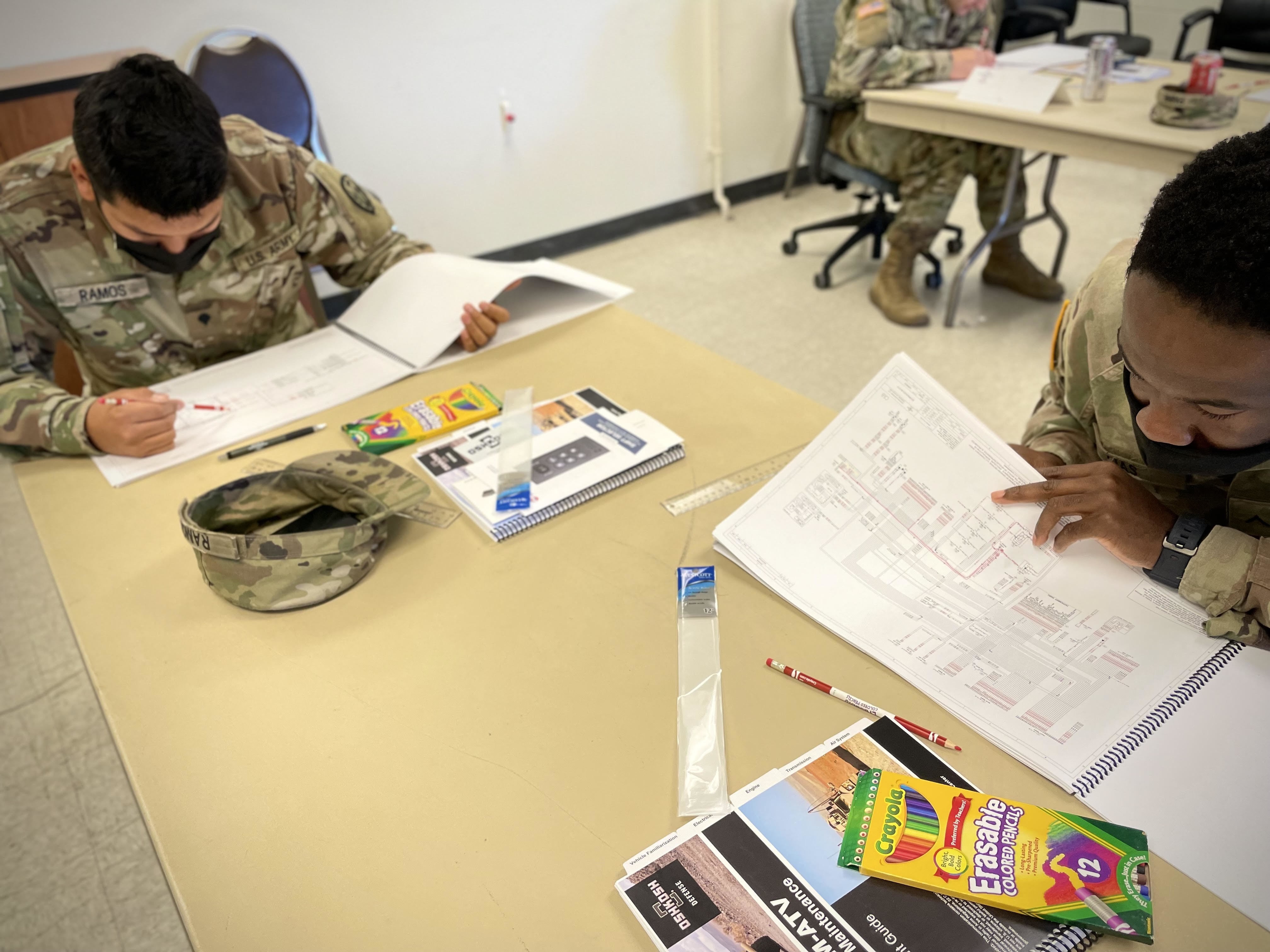

Some of the topics covered were: familiarization, electrical engine, transmission, air system, central tire inflation, system axel and suspension, steering, HVAC, and the automatic fire extinguishing system. Soldiers also cover schematics in depth by learning how electricity starts from the battery to individual components.

The instructor simplified how to troubleshoot electronics by using every day examples such as how electricity is fed from a plug to a computer through the outlet.

“If I did not have this light on, do I need to trouble shoot this laptop?” he asked the class and they all responded simultaneously with a no. “No because I can trace it to the source which is the battery.”

Chief Warrant Officer 2 Jhonathan MercedesZorrilla, 303rd Military Intelligence Battalion maintenance technician, said this training is highly valuable because it focuses on trouble shooting, getting to the root of the issues versus just swapping parts and hoping that fixes the problem. He said it builds skills long term and completes the work faster.

Trainer stated that sometimes Soldiers pick up bad habits with maintenance, whether it is from prior to the military or other workers teaching bad habits. He assists with providing the proper training straight from who wrote the book on their particular standards to assist with the life of the vehicle.

One of the maintenance supervisors, Staff. Sgt. Raul Davila, Headquarters and Headquarters Company, 504th EMIB, said that reading schematics, or electrical diagrams, is a common struggle for mechanics.

“Of you can read a schematic that is 60-70 percent of the job,” he said. “Typical items that go down are sensors and drivability issues.”

As equipment is updated the vehicles in the motor pool are rotated out and new equipment comes in.

“Some Soldiers were never trained on this exact equipment because it is new,” said Sgt. 1st Class Travis Broussard, motor control sgt. “We are receiving more new equipment. Being able to have the manufacture come in and train Soldiers is critical.”

Social Sharing