Leaders who previously served in the U.S. Army Aviation and Missile Command convened online Oct. 7 for an annual update on progress made in the last year.

The 90-minute session touched on topics ranging from personnel readiness, strategic initiatives and supply availability to equipment readiness, data analytics and upcoming events.

AMCOM Commander Maj. Gen. Todd Royar gave the team credit for making vast improvements in the last two years in Soldier, civilian and family readiness, as well as for the marked improvement in responses to workforce surveys.

“By all accounts, the things that the individual commanders and directors are doing at their level are paying off,” Royar said. “By all measures, the positive responses are going up.”

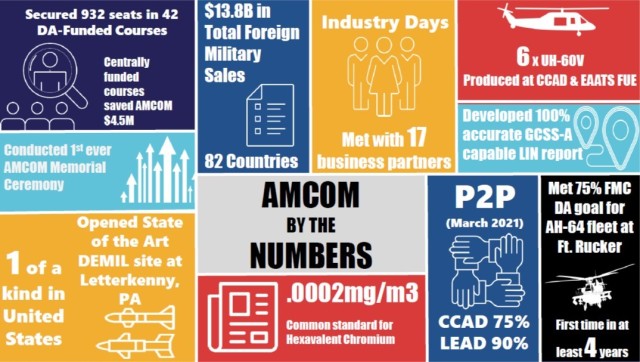

“The first UH-60 Victors were produced on time and delivered on time to the Eastern Army National Guard Aviation Training Site in Fort Indiantown Gap, [Pennsylvania],” Royar said. “[On Oct. 6], we did the ribbon-cutting ceremony for those six aircraft … We were really excited to see that and Col. [Joseph] Parker and his team are just doing phenomenal work as far as getting the next battalion that is already in the pipeline down at Corpus Christi [Army Depot, Texas,] ready for production.”

The commanding general said the organization performed phenomenally in fiscal year 2021.

“We had the highest [fully mission capable] rates that we have ever seen across the Army, and really low [not mission capable supply] rates,” Royar said. “What’s really impressive is down at Fort Rucker [Alabama], they met it met Army [Department of the Army] standards on Apache maintenance – 75% – for the first time in a while.”

“What we’re focusing on for this coming [fiscal year], we want to make sure we’re sustaining the readiness but we’re also looking to the future a little more as far as [organic industrial base] modernization,” Royar said.

“Part of the role of industrial operations is to use our expertise in the organic industrial base to integrate system requirements with the depots and our own G-3, G-4, G-5 teams to make sure that we're loading the organic industrial base – the depots – with the right workload, and helping them execute to meet those requirements,” said AMCOM Logistics Center Director of Industrial Operations Tom Ray.

The concept of an integrated master schedule was borne from an effort to align the modernization of weapon systems with what depots are doing, as well as address any gaps that may exist.

“Really, what it does is it lays out the acquisition lifecycle and the requirements from the weapon system … to make sure that [we’re] identifying those gaps and if we had any date changes that might slide, what the impact to that would be and so that we can correctly prioritize up to [U.S. Army Materiel Command] on how we needed to react to that and what those impacts would be,” Ray explained.

Corpus Christi Army Depot Commander Col. Joseph Parker talked about efforts happening at the Texas base. A new dynamic component repair facility is almost halfway through the third phase of completion.

“We expect [up] to 2 1/2 months to have some type of topping celebration where they put the top and final piece of steel in … and we're off to the races,” Parker said. “We really appreciate everything you did in the past to ensure that we could get that plan funded and on the way, because that's going to save us time, money and be a huge return on investment.”

“Letterkenny [Army Depot, Pennsylvania] is laying the foundation to prepare for the ‘31+4’ signature efforts and programs from Army Futures Command,” said LEAD Commander Col. Rick Allbritton. He spoke on technologies involving additive manufacturing, directed energy, use of robotics on future efforts, as well as new construction of modernized industrial space that will include facilities for air and missile defense production, precision fires, paint and metal fabrication, hypersonic launcher and directed energy.

“Each includes high ceilings and energy-efficient, flexible clean areas and fully postured for future requirements for AMC and AMCOM,” Allbritton said. “Over the next few years, Letterkenny will construct and occupy three new production facilities and they'll serve as a cornerstone for subsequent construction projects. To ensure we're going after the modernization from the whole-of-depot approach, Letterkenny is investing in developing cross functional teams charged with modernizing all aspects of business from facilities to equipment to people to processes.”

U.S. Army Test, Measurement, and Diagnostic Equipment Activity Deputy Director Chris Smith explained how USATA fits into industrial base modernization.

“Most folks see us as a non-standard industrial base,” he said. “We have both characteristics of sustainment maintenance and we look a little bit like a field operating agency.”

USATA, which Smith described as “the keeper of Army standards,” supports all of the commodities in the Army – not only those related to aviation and missiles. One of the ongoing efforts is the simplification of the calibration chain.

“Just an example [is] where we can take two or three things or two or three operations or two or three standards and shrink them down into one,” Smith said. “And, with one operation, we can better adapt to whatever the future force throws at us, and we can be more flexible at the same time so we can respond more to [Multi-Domain Operations].”

Lt. Col. April Kearney, Aviation Center Logistics Command brigade maintenance officer, briefed on progress being made to improve the long-term health of the fleet and creation of a common operating picture.

Because the data was spread across multiple spreadsheets in different shared drives, Kearney said there was no way to correlate the data to help produce a COP or do analysis to inform future actions. After taking hundreds of Excel spreadsheets and putting them into databases, the capabilities exist.

“Over 2 1/2 years we've made significant progress,” she said. “We are taking those databases and we're now incorporating some business intelligence tools that are already preexisting within AMCOM’s data architecture, and the goal is then to be able to run reports to see ourselves and help [U.S. Army Aviation Center of Excellence], AMCOM and across the Army, be able to understand what it will actually take to increase or decrease student throughput for flight school.”

“Thanks for what each and every one of you, not only have done for AMCOM in the past, but as you continue to support AMCOM, [Army Materiel Command] and the Army moving into the future,” Royar said.

Social Sharing