ANNISTON ARMY DEPOT, Anniston, Ala. -- Anniston Army Depot has proudly served the nation and men and women of our Armed Forces. Today marks our 80-year anniversary.

In northeast Alabama, the War Department began construction of an Army Ordnance Depot in 1940. Steps were taken to establish it in the Anniston area. And an initial 10,640-acre tract was acquired. After subsequent land purchases, the depot increased to its present size of 15,319 acres. Originally, it was comprised of storage igloos, ammunition magazines, warehouses and several administrative buildings.

While the installation has endured many changes over the last eight decades, its vision has remained the same – supporting America’s warfighters both in times of peace and in times of war.

From an initial workforce of four employees, the installation now provides employment for approximately 4,000 civilians, military, and contractor employees.

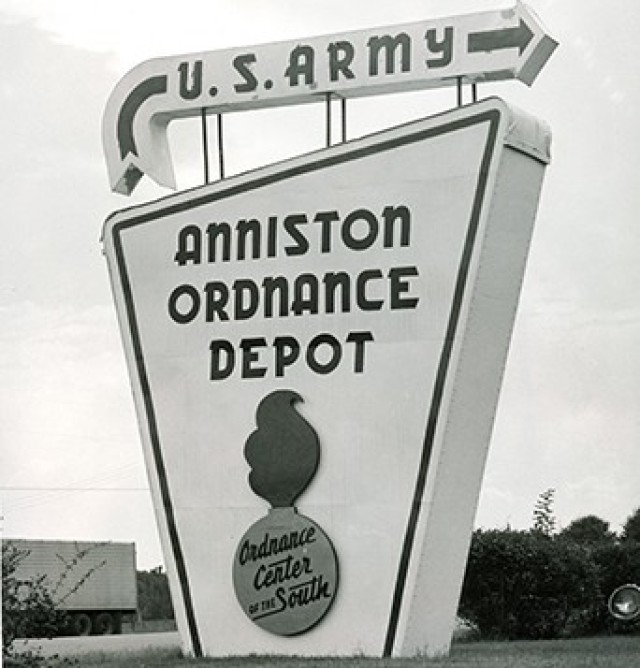

The depot was officially designated the Anniston Ordnance Depot in accordance with the War Department General Order No. 11, dated October 14, 1941.

Nearly a decade later, AOD was assigned a maintenance mission for the overhaul and repair of combat vehicles.

In 1958, John Talley started his career as a trades helper making $1.49 an hour and worked for almost 40 years in various positions.

“In the early 60s, we worked on the M42, M47, M48, and other vehicles and a lot of artillery,” he said. “The Combat Vehicle Repair Facility, about five acres in size, was very impressive. No other depot could do what we did. We were ramping up in support of another conflict. The days were long, working sometimes 14 to 16 hours regularly but we knew the importance of our products.”

When asked about one of his fondest moments, he mentioned the time when the production personnel were working on the M1 Abrams legacy vehicle and a staff member asked him and Dave Stanley how many pounds of nails, screws and washers it took to build one,” he chuckled. “Through it all, the depot has been good to me and my family. In fact, when the war was getting started in 1940, my mom drove a dump truck in the vicinity of the headquarters building over to the canal area, backfilling that space. I’ve got lots of stories to tell.” Talley retired in 1998 as the one the senior leaders in the directorate of maintenance.

In 1962, the facility was renamed Anniston Army Depot, an installation under the jurisdiction of the Army Materiel Command.

That same year, on the east side of the depot, an oval shaped test track where combat vehicles were put through strenuous tests to assure A-1 serviceability of the vehicle was completed and put into action. Measuring 1.2 miles in length and surfaced with approximately 22,000 square yards of asphaltic cement, it is 28 feet wide on the straightway and considerably wider at the curves.

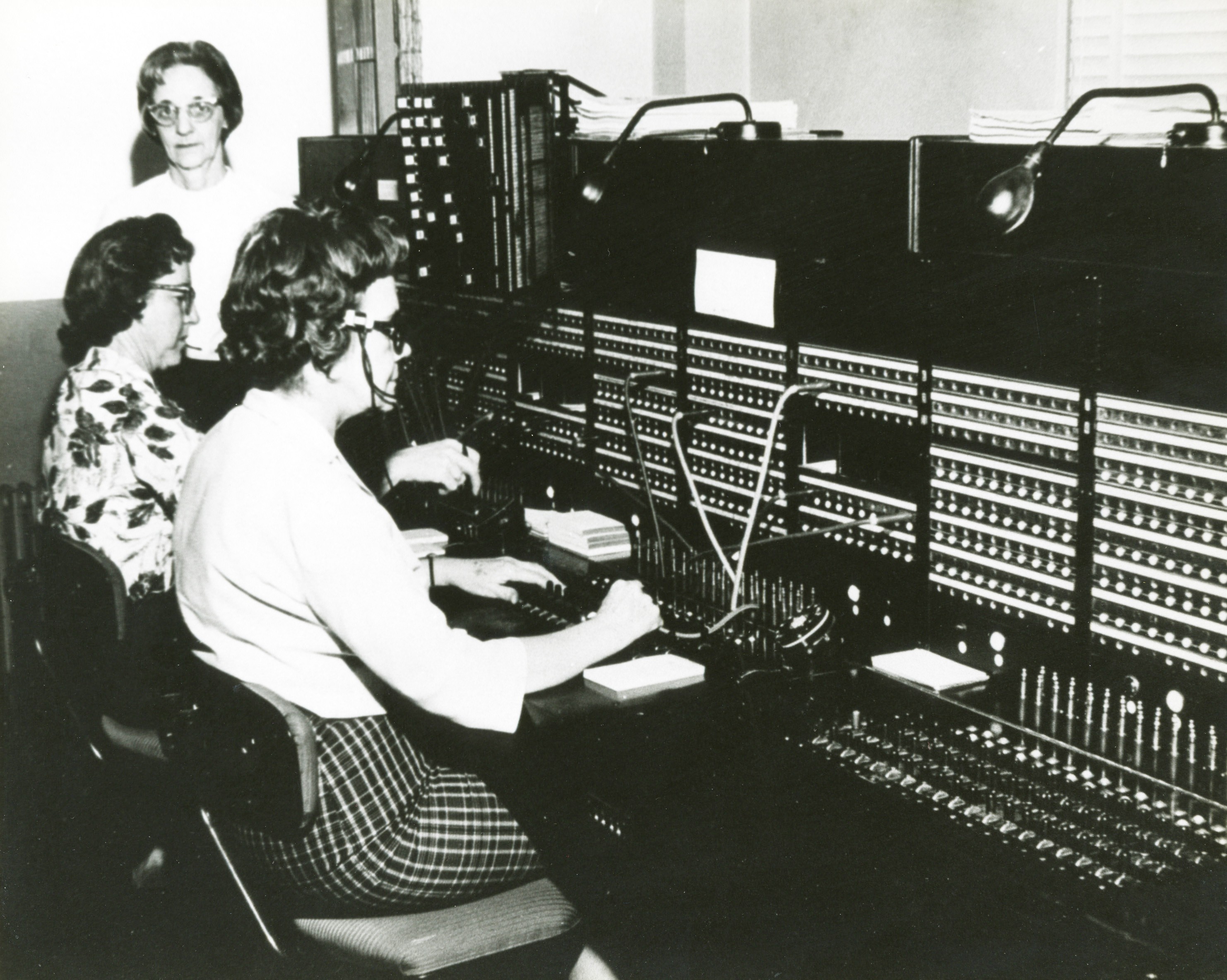

During the 60s, on the west side of the depot, the Facilities Division, which belonged to the Directorate for Services, had the functional responsibility to maintain buildings, road, railroads, structures, grounds, and installed production equipment, as well as provide utility services, fire prevention and protection services, engineering services and custodial services. Fran Henson, who came to work as a clerk in 1962, recalls three planners in the organization. “They did the work and I ordered materials for that work,” she said. “While I used a manual typewriter at school, I was introduced to an electric typewriter here. “Most women did administrative work then, but it evolved over the years.”

In 1963, the maintenance and storage of chemical munitions at ANAD began.

ANAD began repair and overhaul of the M1 Abrams Main Battle Tank in the mid-1980s and was the recipient of towed and self-propelled artillery and light combat vehicle missions as a result of Base Realignment and Closure of 1995.

From its origin to now, the depot has transformed into a state-of-the-art maintenance facility, rightfully earning its reputation as the “Tank Rebuild Center of the World.”

In her 25 years of service, Carol ‘Bea’ Finley, who started 1987 and retired as supervisor of the disassembly branch, said these were some of the best times of her career. “My team and I did what we had to do.” From refurbishing battery boxes in Germany to the upgrade of the M1A1 to the M1A2 here on depot, Finley said there was only one thing she would have changed. “A deployment caused me to miss the birth of my grandson, but I know the work we did was very important,” she said.

As stated by Charles Williams, “the depot has always risen to the occasion regardless of what was going on.” “From combat vehicles to small arms, artillery, missile system components, engines and transmission; we did it all with a historical number of manhours,” he said. “There was lots of travel We had teams in Germany, Italy, England, as well as stateside, in support of the overhaul and repair of various vehicle systems.” Williams began his career in 1973 as a material maintenance specialist and retired as the depot’s director of production.

The 1990s brought about various noteworthy changes, mostly in the form of tenant organizations.

In August 1992, the General Supply Mission was assumed by the Defense Distribution Depot, Anniston, under the command of the Defense Logistics Agency.

In 1993, the depot began leading the way within the Department of Defense in the public-private partnership arena.

“When the P3 efforts began, the workforce was hesitant,” said Talley. “As you can imagine, it was a new topic, there were many unknowns and quite naturally, it wasn’t automatically embraced. But, it turned out to be one of the best things.”

Currently, there are over 98 different partnerships with industry leaders.

The U. S. Army Clearinghouse, which receives, ships, and stores historical artifacts and property on behalf of the U.S. Army Center of Military History, was constructed in 1994.

In 1995, the Anniston Chemical Activity was established to manage the chemical mission under the Chemical Material Agency’s umbrella. On Sept. 22, 2011, the agency announced the successful completion of an eight-year mission demilitarizing ANAD’s chemical munitions, which represented seven percent of the nation’s original chemical stockpile.

In October 1998, operational control of the depot was transferred from the Industrial Operations Command to originally, the TACOM Life Cycle Management Command. The name changed to the U.S. Army Tank-automotive and Armaments Command in 2019.

Also in October 1998, the depot’s Directorate of Ammunition, embracing the conventional ammunition mission, became a tenant function. The Anniston Munitions Center was established under the control of Blue Grass Army Depot and Joint Munitions Command.

Today, the depot’s primary mission has grown to encompass overhaul and repair of all heavy and light combat vehicles (with the exception of the Bradley), artillery, assault bridging, small caliber weapons and non-tactical generators, locomotives and rail equipment.

Utilizing a highly skilled workforce, the intricate work that was once completed internally has expanded to include on-site support in 42 locations throughout the continental United States and in six countries around the globe.

After 80 years of excellence, we continue to proudly supply the warfighter – at home and abroad - and look forward to being around for many, many more years to come.

Social Sharing