ABERDEEN PROVING GROUND — A team of Army and academic researchers reviewed a decade worth of studies examining fundamental physics in order to improve aircraft engine performance under extreme conditions.

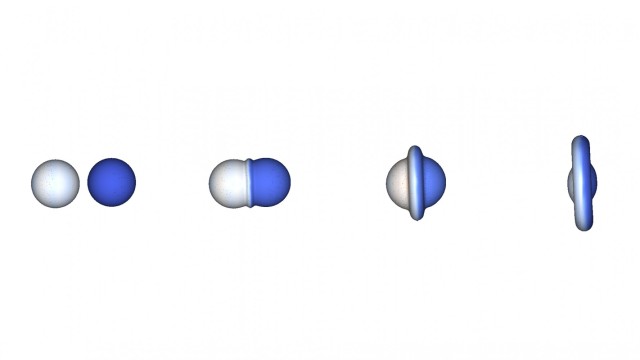

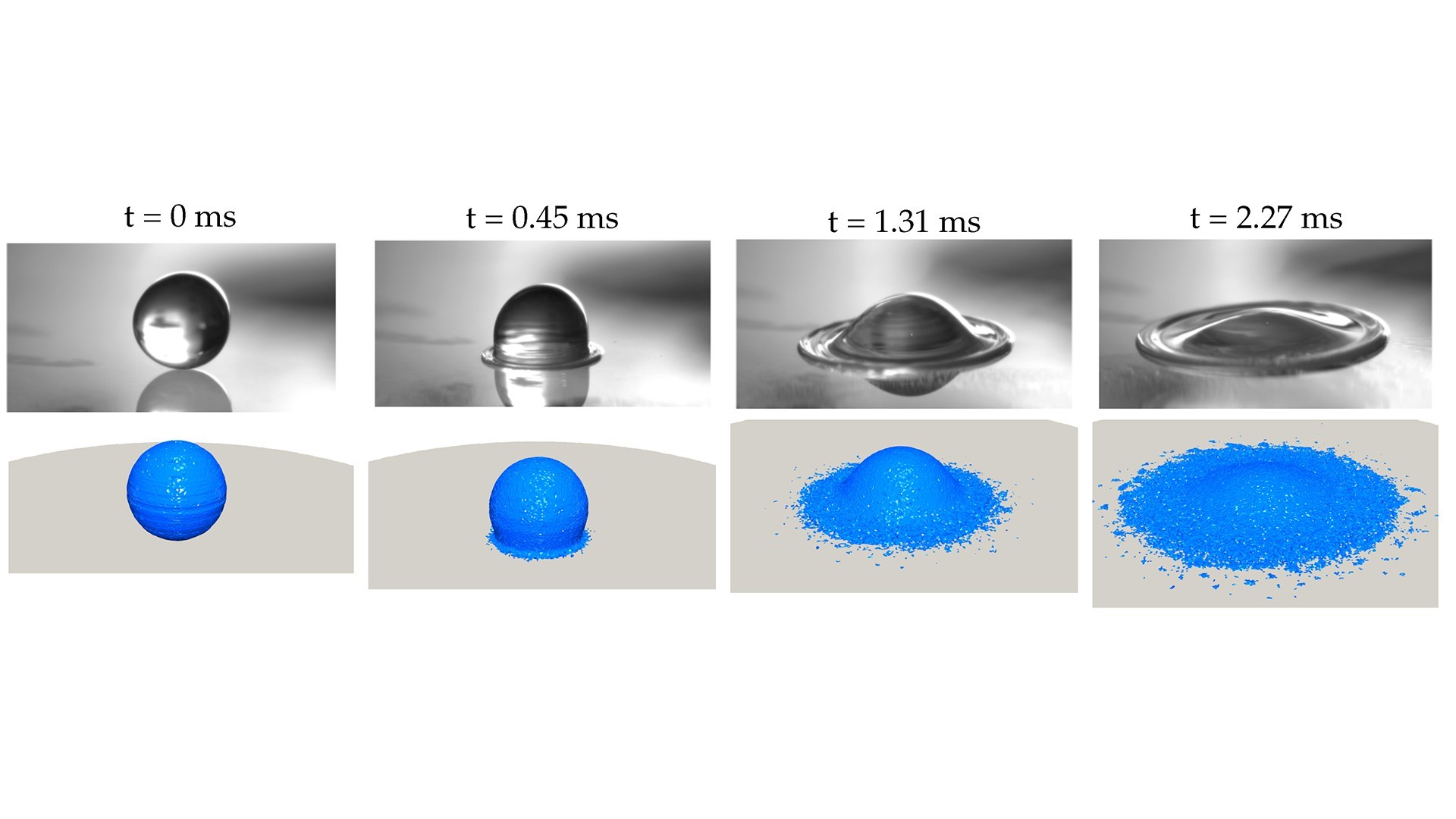

Military aircraft operate in demanding environments, such as sand, dust clouds, runway debris and even volcanic ash. Micro-particles from these hazards can wreak havoc on gas turbine engines.

Researchers from the U.S. Army Combat Capabilities Development Command, known as DEVCOM, Army Research Laboratory, teamed up with colleagues from the University of Maryland, College Park, the University of Cincinnati and the Institute of Thermal Turbomachinery at the Karlsruhe Institute of Technology in Germany, to look at the literature with a critical new eye. Their peer-reviewed work is published in the American Society of Mechanical Engineers, Applied Mechanics Review, “A Critical Review of Physical Models in High Temperature Multiphase Fluid Dynamics: Turbulent Transport and Particle-Wall Interactions.”

“There is a connection between understanding the fundamental physics and the advancement of engine technologies,” said Dr. Luis Bravo, Army researcher. “After reviewing the last decade of state-of-the art research, we see that the interactions between engine components are often missed in contemporary models and this has a profound impact on predicting unsteady engine performance.”

The review led to a formal partnership, known as a Cooperative Research and Development Agreement, with Pratt and Whitney, the U.S. Navy, University of Maryland and University of Cincinnati. The collaborative effort will use artificial intelligence and machine learning to improve modeling and simulation and develop better design and mitigation solutions.

According to Bravo, the review helped to focus their future research on critical challenges in propulsion and a new research direction leveraging emerging breakthroughs in AI/ML.

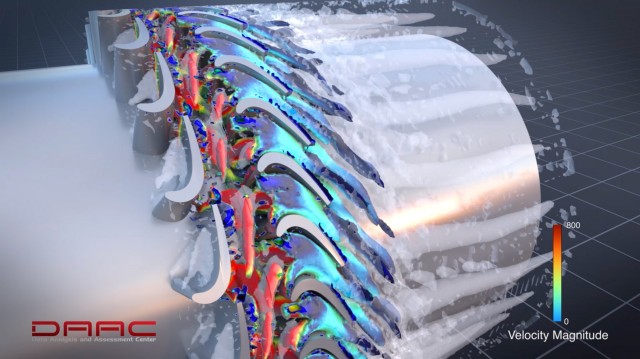

NASA and the aviation community published a roadmap for the future and identified one of its grand challenges as the development of computational fluid dynamics full-engine simulation. In a NASA technical report, this vision will revolutionize computational aerosciences by 2030 with advanced simulation capabilities.

“This has the capability of providing us full-access to the engine internal flow dynamics continuum by integrating all of the engine components,” Bravo said. “The recent breakthroughs in AI/ML are key in making this a reality to create on the fly physics-informed surrogate models that can explore the entire design space. This tool will dramatically decrease engine design cycles and allow in-situ health monitoring.”

Understanding how the components of a gas turbine engine interact under any conditions will be enabled by creating a digital twin. The researchers emphasized that machine learning has increased potential to solve engineering challenges as it matures. They said it will allow them to try out new combustion designs with predictive models and give unique and valuable visualizations.

“I am confident that with the current advancements in artificial intelligence and machine learning tools and high-powered GPU computing resources, we are at the right time now to use this approach to accomplish complex computationally intensive full-scale gas turbine engine simulations in relatively shorter time with high fidelity,” said Dr. Muthuvel Murugan. “AI/ML tools can greatly contribute to performance simulations of high-fidelity digital twin engine models on-the-fly and allow us to use real-time engine operations control and cost-effective sustainment framework of Army aircraft.”

Advanced engine design will be aided by countless high-fidelity simulations from supercomputers in the future.

“There is a need for physics-informed smart design going forward,” said Dr. Anindya Ghoshal, Army researcher and DEVCOM ARL Turbine Power Research team lead. “Understanding the design space, gas turbine engine component interaction models, compression models and machine learning algorithms will help us to understand how the engine will operate under different regimes.”

Ghoshal and his fellow Army researchers have been experimenting with advanced thermal barrier coatings and next generation materials to protect gas turbine engines from harmful particles. They are also studying advanced aeroengine concepts with academic and industry partners for future Army aircraft. He said their work will not only save lives, but essentially lead to the development of more powerful Army helicopters.

“This is really the culmination of our work at ARL in Turbine Power Sciences,” he said. “We’re addressing one of the grand challenges in the propulsion community. We can do this.”

In setting a research direction that looks at the interface of full-engine modeling and simulation and machine learning to provide the next generation of design tools, the researchers have lofty goals, but they are confident it can be accomplished.

“There is always a level of risk in basic research, but we are confident we have the right expertise here at ARL and with our partnerships across industry and academia to make a difference,” Bravo said. “We are also very fortunate to be able to leverage the tremendous supercomputing resources sponsored by the DOD High Performance Computing Modernization Program Office.”

As researchers pursue mitigation strategies for sand, ash, dust and even rain and humidity, future aircraft–both civilian and military–will reap the benefits in safety and performance.

“I feel extremely happy for my key role in this grand challenge project of enabling highly durable sandphobic coatings and high-efficiency/high-power density gas turbine engines for future Army rotorcraft,” Murugan said. “The technology outcomes from this project can greatly enhance the safety and durable performance of Army vertical take-off and landing aircraft.

Army researchers imagine more power from the same form, fit and factor, that will also be more efficient.

“Personally, I am inspired by working on futuristic propulsion technologies that will deliver technology overmatch for the Soldier and ultimately for our nation,” Bravo said.

Visit the laboratory's Media Center to discover more Army science and technology stories

As the Army’s national research laboratory, ARL is operationalizing science to achieve transformational overmatch. Through collaboration across the command’s core technical competencies, DEVCOM leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more successful at winning the nation’s wars and come home safely. DEVCOM Army Research Laboratory is an element of the U.S. Army Combat Capabilities Development Command. DEVCOM is a major subordinate command of the Army Futures Command.

Social Sharing