TOBYHANNA ARMY DEPOT, Pa. Aca,!" Using cutting-edge technology, Tobyhanna visionaries have created a workspace that will showcase, test and demonstrate new methods and systems.

The Depot Maintenance of the Future (DMOF) facility is a 10,000 square foot, technological innovation designed to stimulate new ideas and influence advancement of work techniques. Featuring top-quality amenities, the facility will serve as a working laboratory for new technology and processes.

Aca,!A"DMOF is our vision for how Tobyhanna will look and operate in 2015 and beyond,Aca,!A? said Col. Ron Alberto, depot commander. Aca,!A"It is a working laboratory to test new tools, processes, equipment and facilitiesAca,!"we will propagate what works across the depot and will scrap what does not fit into our system. The greatest part of DMOF is that it is designed as a flexible and agile workspace that we can rapidly reconfigure to new workload, processes or customers. I expect it to be a selling point to future customers for years.Aca,!A?

The facility includes a flexible design, electronic technical data, the latest technologies and equipment, and electrostatic discharge (ESD) control. It is also visually attractive and environmentally friendly. DMOFAca,!a,,cs central location allows easy access to nearby work centers to view and evaluate the prototype equipment, processes and facility.

Aca,!A"The cutting edge design features elements that have never been seen here before and are demonstrated through the physical space as well as the virtual,Aca,!A? said Thomas Sincavage, lead architect, adding that everything is going to be a very unique experience. Aca,!A"DMOF will encourage people to embrace the possibilities. WeAca,!a,,cre taking the next steps forward, building on and improving things for our future.Aca,!A?

Employees in two Command, Control and Computers (C3)/Avionics Directorate organizations will be the first to work in the DMOF. Workload in the Navigation Systems and the Computer Service and Repair branches was selected based on specific characteristics.

Aca,!A"We are moving the Tobyhanna Multimedia Language Lab (TMLL) and the Medical Communications for Combat Casualty Care (MC4) from the Computer Service and Repair Branch,Aca,!A? said George Bellas, C3/Avionics director. Aca,!A"Both of these systems are high tech, new equipment consisting of state-of-the-art computers.Aca,!A?

Bellas noted that TMLL is deployed to countries to teach primarily English using personal computers and MC4 consists of a handheld computer system that allows medics in the field to access an injured SoldierAca,!a,,cs complete medical record.

Aca,!A"MC4 integrates, fields and supports a comprehensive medical information system enabling lifelong electronic medical records, treamlined medical logistics and enhanced situational awareness for Army tactical forces,Aca,!A? Bellas said. Tobyhanna configures the systems for fielding, upgrades the hardware and software, and performs repair in the field through Forward Repair Activities.

Aca,!A"Using the DMOF to roll out and test new concepts, procedures and equipment will enhance our capabilities in and around the depot,Aca,!A? said Jerry Dougher, C3 Division chief. The selection of the MC4 and language labs workload will show the rest of the depot work force some of the capabilities that reside in parts of the depot that are not commonly on display.Aca,!A?

The DMOF will provide an environment of continuous improvement that can help employees repair older components faster and more efficiently.

The Navigation Systems Branch showcases TobyhannaAca,!a,,cs capability to design, build and use modern automated test equipment (ATE) such as the PXI (PCI eXtensions for Instrumentation) System and the Agilent 3070 Board Test System. Branch employees will overhaul AN/ASN-128 Doppler Global Positioning System (GPS) Navigation Systems, AN/ARN 149, 147, 123 and 89 receivers, and Miniaturized Airborne GPS Receivers (MAGR) in the new facility.

Aca,!A"Although these systems are older legacy systems, we are setting up new state-of-the-art test equipment in the DMOF repair process,Aca,!A? Bellas said.

The branch chief noted that the new benches, climate control system and improved lighting all contribute to a better work environment. Aca,!A"The ESD controls being implemented meet the latest standards and will allow the shop to take in new workload with the latest technology that contains highly sensitive components,Aca,!A? Anthony Gentle said.

The benefits of the new workspace are many, according to Bellas. From the natural lighting piped in from light tubes to the superior air conditioning and exhaust system, the environment will provide outstanding working conditions, he remarked. Aca,!A"We expect additional benefits from the enhanced ESD equipment and procedures, paperless environment, the conveyor system. and the new test equipment and processes,Aca,!A? he said.

Another main feature of the DMOF is its flexibility. As workload requirements change, the room can be converted to support any mission.

Aca,!A"Although the depot has embraced Lean concepts, the DMOF facility was designed using Lean principles from the start,Aca,!A? said Joseph Wassell, Avionics Division chief. Aca,!A"The modular design of the work area promotes efficiency and allows for quick-reaction restructuring due to changes in workload,Aca,!A? he said, adding that the DMOF concept will serve as a steppingstone to facility improvements throughout the depot.

Aca,!A"It will be a constant reminder of how flexible the depot needs to be in order to accommodate future systems and their specific requirements,Aca,!A? Wassell said.

DMOF features modular moveable walls and doors. Glass partitions will provide privacy without confinement, and acoustic materials will ensure the area is quiet. The workspace also includes new ergonomic workstations with a variety of accessories that can be added to precisely suit the needs of different applications and users.

These workstations can increase a workerAca,!a,,cs productivity by providing easier access to test equipment on adjustable height shelving, access to technical data on monitors attached with adjustable swing arms and customized drawer storage providing shadow boxes for standard tools, according to Patty Curran, project leader. The conveyor systems, which are also modular and reconfigurable, will enhance efficiency by providing an improved material process flow, she added.

An overhead utility grid system will provide power, networking, compressed air, and even fume extraction, to the workstations that require those utilities. The grid provides an agile workspace, frees up floor space and enables quick reconfiguration.

Curran explained that unlike a raised floor system, which requires the relocation of furniture and equipment whenever utility changes are needed, the overhead utility grid enables reconfiguration of the area with very little disruption to other processes.

Increased productivity, healthier environment and lessening the depotAca,!a,,cs environmental footprint were taken into consideration when designing the DMOF facility.

Aca,!A"ItAca,!a,,cs a space thatAca,!a,,cs going to have movement in it,Aca,!A? Sincavage said. Aca,!A"This is not the conventional design most people are used to seeing,Aca,!A? he said, pointing out that this space introduces natural light and open space.

Lighting for this new area is intended to be environmentally friendly, energy efficient and aesthetically pleasing.

Solar panels were placed on the roof to provide energy for such things as ambient and task lighting. Aca,!A"The solar panels will power light emitting diode (LED) strips on each bench,Aca,!A? said Curran. Aca,!A"Strips consisting of 50 little dots will light work areas more efficiently than the standard bench lights or light bar.Aca,!A?

Solar tubes will provide natural light to the room. Unlike old-fashion skylights, solar tubes use mirrored surfaces to expand the amount of natural light made available to the room, while keeping heat-loss to a minimum due to their small roof opening.

Curran stated that natural lighting increases the comfort level of employees and also makes them more productive.

The roof is made of a reflective material and designed to provide water reclamation. This feature will enable water that is collected from existing roof drains to flush toilets in adjacent rest rooms. Included as part of this system is an ultraviolet disinfection system that sanitizes the water being sent to restroom fixtures.

Aca,!A"I think all the employees who will be working in the DMOF will come to appreciate their surroundings,Aca,!A? Dougher said. Aca,!A"IAca,!a,,cm looking forward to hearing what they have to say about the new and different environment.Aca,!A?

The next feature of the area is the presence of electronic technical data. All technical data will be available electronically at each workstation.

Aca,!A"This feature assures that users who are accessing technical reference orders, technical publications and test procedures will be using the most current version that is available,Aca,!A? Curran said. Aca,!A"Some workstations will be equipped with dual monitors, so they can access test procedures and schematics concurrently.Aca,!A?

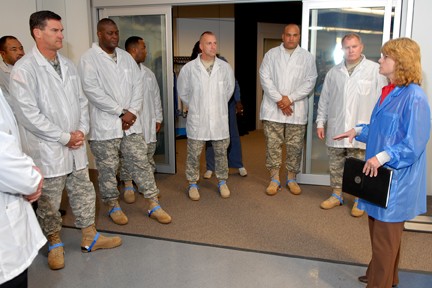

An ESD control team, composed of members from the Productivity Improvement and Innovation and the C3/Avionics directorates researched all aspects of ESD control, ranging from dissipative floors to ESD smocks.

Aca,!A"As a result of their involvement in this project, the Depot Maintenance of the Future area is expected to be a model area for ESD control,Aca,!A? Curran said.

Wassell agrees. Aca,!A"The built-in ESD procedures reinforce the more stringent requirements of todayAca,!a,,cs advanced systems and emphasize ESD processes required for AS 9110 certification.Aca,!A?

The Information Management Directorate (DOIM) specified workstation computers and audio/visual support. In addition to providing improved sound and video systems, DOIM is also using this area to demonstrate the many uses of three dimensional 3D holographic projection systems.

The DMOF facility will also feature state-of-the-art audio-visual presentations to demonstrate TobyhannaAca,!a,,cs capabilities to customers and visitors.

Aca,!A"This facility will deliver a 3D visual and immersive sound experience that brings to life TobyhannaAca,!a,,cs message of support to the warfighter,Aca,!A? explains Ed Farrell, chief of the Commodity Management Division in the Business Management Directorate. Farrell is the team lead on the marketing component of the DMOF project.

Using descriptive scenarios, a video projected on the glass walls of the facility will depict how Tobyhanna ensures support to the warfighter in such areas as owning the night, force protection and communications, he explained. A power wall will present a 3D production on the future of depot maintenance, depicting how Tobyhanna can virtually project its capabilities wherever joint forces operate. Depot engineers will use the power wall for computer-aided engineering demonstrations as well as workload design and development with customers.

Holographic staging and touch light displays complete the advanced presentation format. Touch light is an interactive tool using infrared technologies that will allow customers and visitors to interact with 3D models of Tobyhanna-support equipment.

Aca,!A"As we conduct our external marketing, we will encourage customers and DoD leaders to visit Tobyhanna to experience first-hand our capabilities in these unique presentation formats,Aca,!A? Farrell concluded.

Aca,!A"Employees will see a definite transformation as they walk from the depot of the present to the depot of the future,Aca,!A? Sincavage said. Aca,!A"IAca,!a,,cm looking forward to seeing everything come together as envisioned.Aca,!A?

Several depot organizations, such as the Process Engineering Division, Safety Office and the union, examined 3D model layouts and made recommendations for improvements.

Aca,!A"The only reason that this aggressive schedule has been a success is due to the cooperation between many depot organizations and outside vendors,Aca,!A? Curran said. Aca,!A"It is this cooperation that has kept this project moving forward.Aca,!A?

Sincavage concurs. Aca,!A"Everyone working on this job has been outstanding,Aca,!A? he said. Aca,!A"TheyAca,!a,,cve really had a vision to see this project through to the end.Aca,!A?

Tobyhanna Army Depot is the Defense DepartmentAca,!a,,cs largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network. TobyhannaAca,!a,,cs missions support all branches of the Armed Forces.

About 5,600 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army CECOM Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the commandAca,!a,,cs mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing