When SARS-CoV-2 was emerging on the world’s stage in early 2020, researchers and scientists across the Walter Reed Army Institute of Research were mobilizing their resources to combat it. Members of its Pilot Bioproduction Facility, the DOD’s unique small-scale manufacturing facility for vaccines and biologics, were no different.

There was just one problem—the building was offline, coming out of a multi-year reconstruction to modernize, improve, and expand its capabilities.

Founded in 1953, the PBF has a long history of manufacturing vaccines and biologics to protect against diseases of military relevance. Working with scientists at WRAIR as well as external partners like academic laboratories or biotech companies, the PBF manufactures small-scale batches of experimental products intended for testing in clinical trials.

Vaccines for diseases, like Japanese encephalitis and hepatitis A, now available to Service Members and the public, were manufactured through the PBF’s manufacturing pipeline. They have also assisted novel WRAIR technology by aseptically filling vials of bacteriophage—or viruses that exclusively infect specific types of bacteria—for patients with life-threatening multidrug-resistant infections.

“Operating a manufacturing facility is extremely complicated and highly regulated. Any product we make that goes into humans is carefully tested and controlled,” said Dr. Stasya Zarling, associate director at the WRAIR PBF. “As a result, the manufacturing that goes into those products is also closely scrutinized, particularly when we’re completely restarting production.”

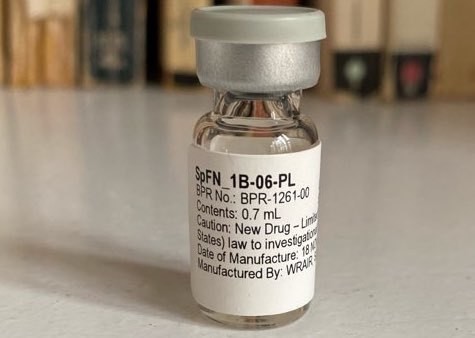

As such, the PBF staff threw themselves into their work, working around the clock to oversee the completion of building renovations, the calibration and qualification of equipment according to the U.S. Food and Drug Administration’s current good manufacturing practices and development of a manufacturing process for WRAIR’s COVID-19 vaccine, known as spike ferritin nanoparticle.

“Even outside a pandemic, there’s very little room for error when manufacturing vaccines. While we were working as quickly as possible, we also had to ensure our facility, processes and products were manufactured effectively,” said Maj. Jeffrey Froude, director of the WRAIR PBF.

Their hard work paid off in December 2020, when the first batches of SpFN rolled off the production line. From there, PBF staff performed the final quality control testing before an application to use the vaccine in a clinical trial was submitted in early March. Receiving approval from the FDA, the trial began on April 6th.

“The PBF is a unique organization, not just within the DOD but the whole U.S. government,” said Maj. Froude. “While we work with a diverse array of collaborators inside and outside government, our work—paired with other product testing capabilities at WRAIR—helps make sure that vaccines and biologics needed to protect Soldiers move into advanced development and hopefully are licensed for use.”

Rick Millward, WRAIR PBF associate director, points out, “The PBF fills a crucial need in a very important part of the vaccine production pipeline – Phase 1, or “first off the bench,” production suitable for Phase 1 clinical trials. Although this is a required step in this process, the availability of independent facilities willing to manufacture a full range of Phase 1 production under one roof is extremely limited.”

Social Sharing