It was clear to William Lamond the wheels on the robots would need to be repaired or replaced if they were to continue delivering supplies to work areas around the depot.

The electronic industrial control mechanic’s idea to update an age-old practice earned him a monetary award via the Tobyhanna Army Depot’s Suggestion Program. The new process spends less time and money while keeping the mission moving. Lamond works in the Production Engineering Directorate’s Mission and Support Division.

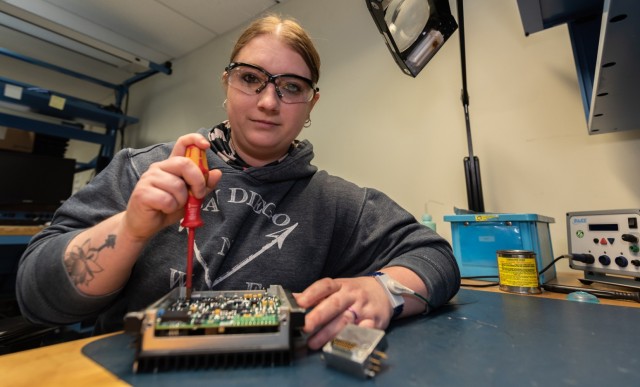

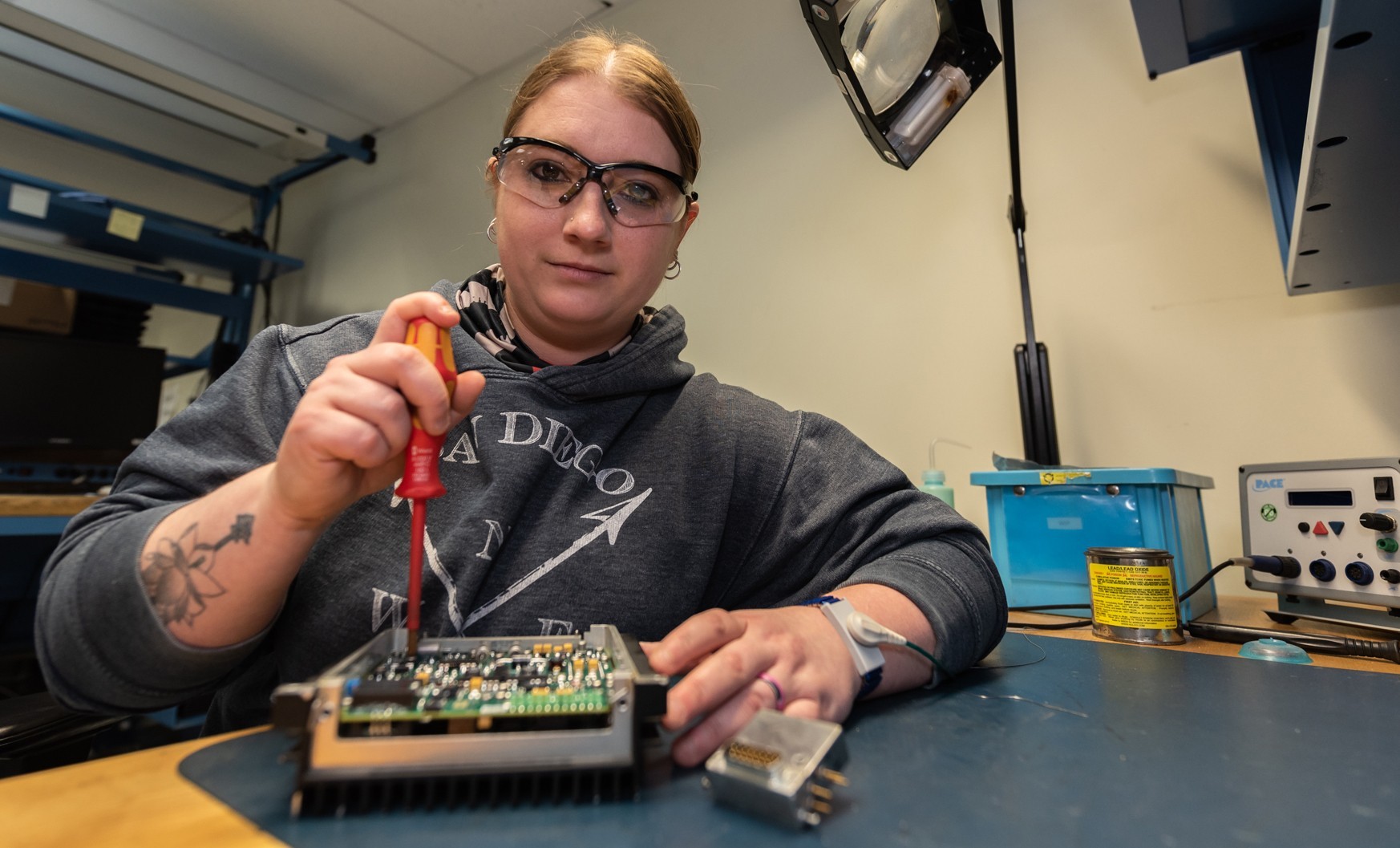

Amanda Cortino also earned a cash bonus after pitching her idea to alter repair methods for a power supply unit. As a work leader in the C4ISR Directorate’s Flight Control Branch, she was able to convince officials there would be fewer test failures by implementing her suggestion. Cortino recently started a detail as a production controller in the Production Management Directorate’s Avionics and Sensors Program Management Division.

Anyone can submit an idea through the Ideas for Innovation Suggestion mailbox at usarmy.tyad.usamc.mbx.asp@mail.mil, according to Christopher Gogola, program manager. He explained the submission form, ELTY 1045, Tobyhanna Army Depot Ideas for Innovation, is located on the depot’s intranet site under the local depot forms link. People looking to make a difference must follow the steps outlined in the guidance posted to the Programs-Services link, also on the intranet site, he added. Gogola is a lead process improvement specialist in the Resource Management Directorate’s Process Improvement Division.

“When submitting a suggestion, the more detailed information on the suggestion form the better,” said Gogola. “The suggestor must write like they are selling their idea because they are.”

Lamond and a team of mechanics maintain a fleet of vehicles used to deliver supplies to support Army readiness. In particular, the automated guided vehicles (AGV) -- unmanned, wire guided forklifts – which are programmed to travel along a black track that winds through the industrial area.

“The wheels were showing signs of wear and tear after years of continuous use,” said Lamond, who realized the existing method of replacement was costly and time consuming. “I knew there was a better way to keep these legacy vehicles rolling.”

Relying on years of experience as a mechanic, he worked with a local vendor to see if they could repair wheels for the 10 robots still in service at the depot. Once requirements were established and a partnership formed, Tobyhanna was able to cut costs by having the wheels recapped using the same hub versus replacing the entire assembly.

“Maintaining these ageing vehicles has been trying at times due to parts not being available and extreme costs when we were able to procure them, said Paul DePrimo, Mobile Equipment Branch chief. “Employees like Bill look for ways to provide a cost savings and his suggestion to try recapped wheels worked out for us in the end.”

This was Lamond’s first experience with the Suggestion Program.

“It’s rewarding to know my coworkers and the depot can benefit from my ideas,” he said.

Cortino was repairing power supply units for AN/ARC-231Airborne Integrated Terminal Group assets when she realized test rates could be improved by making a simple change to the process.

Cost savings were realized after Cortino discovered it was possible to replace a component called the filter captor instead of a circuit card assembly. The component, which connects the power supply unit to the test station, often comes in corroded or broken, she explained.

“To change a power supply you have to take the whole radio apart,” Cortino said. “One day I saw a pin was broken so I decided to see if I could order a replacement part. A procedural change that would fix the connector problems.”

Process improvement strategies benefit Tobyhanna Army Depot and its customers by cutting costs and refining repair cycle time. Innovative ideas submitted through the suggestion program are aligned with the depot’s long-range strategic plan, Toby 2028, specifically the Invest in Our People line of effort.

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for command, control, communications, computers, cyber, intelligence, surveillance and reconnaissance (C5ISR) systems across the Department of Defense. Tobyhanna’s Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C5ISR provider of choice for all branches of the Armed Forces and industry partners.

Tobyhanna’s unparalleled capabilities include full-spectrum logistics support for sustainment, overhaul and repair, fabrication and manufacturing, engineering design and development, systems integration, post production software support, technology insertion, modification, foreign military sales and global field support to our joint warfighters.

Social Sharing