ANNISTON ARMY DEPOT, Ala. -- Each month the Anniston Army Depot Safety Office follows the Target Zero Accident Prevention Program calendar as a guide for targeting specific accident prevention measures relating to certain established programs. That calendar is located on the Safety office intranet page.

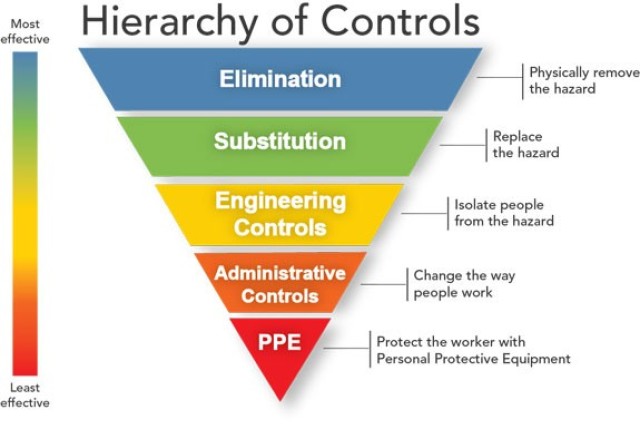

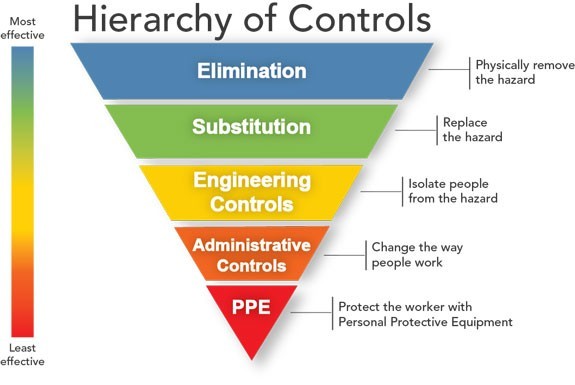

The focus area for March is Personal Protective Equipment; more commonly referred to as PPE. PPE is the last resort in the hierarchy of controls to eliminate hazards, and should never be the first option when attempting to eliminate a hazard.

The primary goal of hazard control, utilizing the hierarchy of controls, is to eliminate the hazard. Elimination of all hazards associated with a process or project can be very difficult due to many influencing factors associated with the work process. Elimination is not impossible, but in many cases it requires complete realignment of a job which can be costly and add valuable time to the process. The goal is to effectively eliminate or control hazards, and to create a safe environment where we do not accept unnecessary risks.

The second option to controlling hazards is substitution. Examples of substitution to eliminate or control hazards can be found all over ANAD. A perfect example is in one of our shops. A wash primer was being used which contained harmful chemicals. With the aid of research by the Directorate of Production Engineering, a replacement chemical was identified that would still meet the requirements of the job. The replacement chemical eliminated the hazardous chemical exposure to the employees who work the process each day.

Another option within the hierarchy is engineering controls. Well-designed engineering controls can be highly effective in protecting employees. The initial costs can be high but, over the long-term, the operating costs are effective. Engineering methods can be effective by controlling employee exposures at the source. These methods are used quite often at ANAD as we put controls in place like ventilation to pull fumes away and protect employees. Other types of engineering controls include ergonomic improvements or fitting the job to the worker not the worker to the job. An employee could be using an air tool to remove a part from a vehicle instead of a wrench or ratchet bar, which could cause strains or other types of muscle and joint injuries. By equipping the employee with the correct tool to perform the job you eliminate potential stressors that may result in injury from long-term or short-term exposure.

Administrative controls are used with existing processes where hazards cannot be effectively controlled via elimination, substitution or engineering controls. These type of controls may include implementation of a worker rotation program, detailed work instructions or something as simple as warning signs in hazardous areas.

PPE is a large part of every organization’s focus; from safety glasses and hearing protection to respiratory protection. The details of the ANAD specific PPE requirements can be found in ANAD regulatory policy 385-4 PPE.

ANAD is committed to ensuring that our employees are given the best possible protection from hazards. The cooperative efforts from management and employees help to establish and maintain a safe and healthful working environment here at the depot. Every employee provides input that aides in establishing PPE requirements for the work area. The ANAD 385-4 regulation details these requirements from top level management all the way to the floor level employee. It is very important when PPE is chosen as the means of hazard control that it is worn and worn properly.

Hazard control is a very important topic in industrial safety. As you have read in the paragraphs above, it involves input from many different areas; from standards to floor level employees. Safety is a 24/7, 365-day commitment, and all employees are responsible for ensuring they are working safely each day.

Social Sharing