How do engineers know that the weapons and ammunition that they provide Soldiers will function as intended? How can systems be fielded faster?

Using modeling and simulation (M&S) tools can help determine if software or products meet the requirements or specifications that guide their development. Moreover, such tools also save time and money since modeling is usually a cheaper and faster way to mature items than the traditional method of cutting metal, testing, fixing flaws and repeating the process.

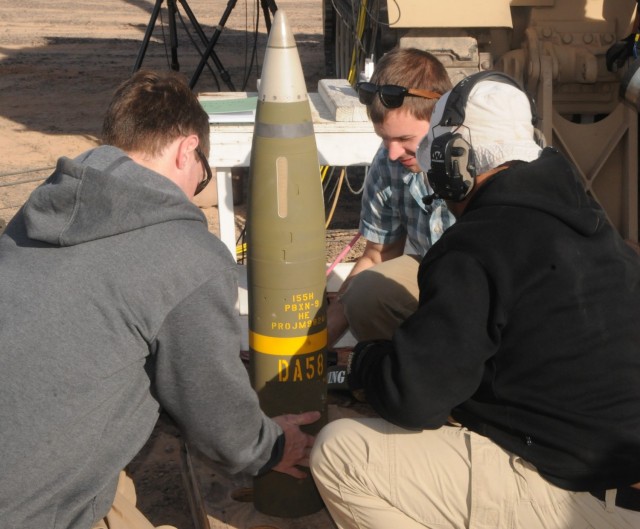

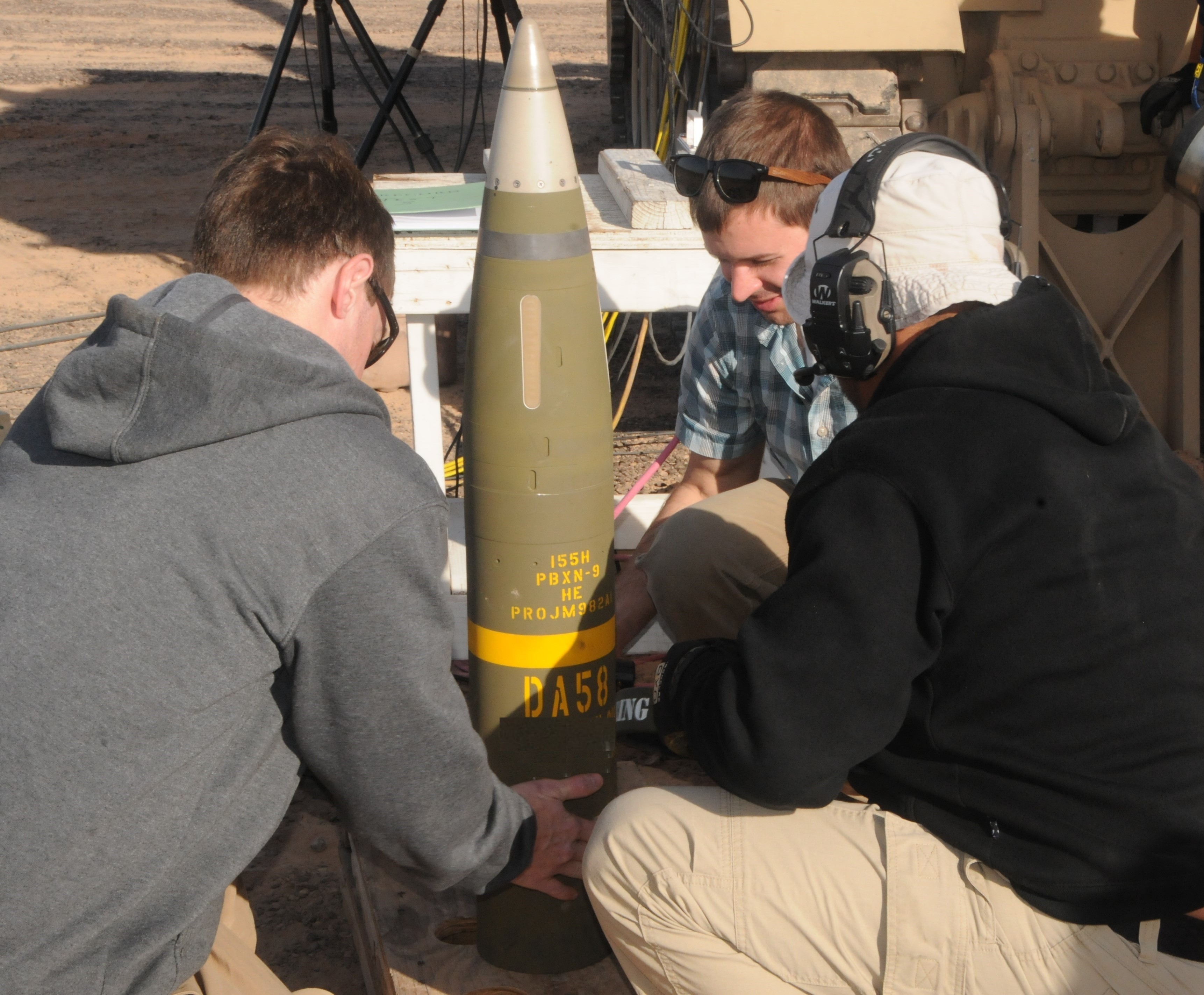

A notable example of how modeling and simulation can yield impressive results is the M982 Excalibur, a 155 mm extended range guided artillery shell. It was developed as a longer-ranged alternative to conventional artillery shells, with GPS guidance for improved accuracy.

“Without the physics models we would have never been able to field the Excalibur projectile in the actual short amount of time it took to design it and field it,” said Donald Carlucci, a Senior Research Scientist at the U.S. Army Combat Capabilities Development Command Armaments Center, located at Picatinny Arsenal.

“The models were absolutely critical to getting that system into the field,” Carlucci added. ”I think the Government/Industry team probably fielded Excalibur in about half the time it would have taken had we done it the traditional way, ‘test, fix, test.’” In addition to time, costs were also significantly reduced.

Modeling and simulation is used throughout the U.S. Army and other Joint Forces to create and analyze digital prototypes of physical models to predict their performance in real-world scenarios.

M&S encompasses the physical, mathematical, or logical representation of a system, entity, phenomenon or process. That serves as a basis for simulations to generate data to guide management or technical decisions.

While models can be very valuable tools, they also have varying degrees of accuracy and maturity. Even less accurate models can be bolstered with actual test data to enhance the development of items.

“There are several types of modeling that go on at Picatinny Arsenal,” said Carlucci. “The lowest level of it is what we call ‘physics models’. Those physics models are essentially calculations on physical phenomena. What I mean by that is, we can figure out the pressure on a surface when a fluid goes by, and then we can determine whether a piece of metal is going to break when it experiences this loading, or is acted on by a different force.

“We can determine when and if things will break or whether they will fly properly. There are physics models that determine how chemicals are going to react with one another when you put two or more together, or burn them together. We can do that for explosives, for pyrotechnics, and that kind of stuff. So, that’s one type of model. A great example would be the prediction of a component in a projectile that might then be tested and recovered--the result compared to the model. If it worked properly or deformed as predicted, the model did its job.”

Carlucci said another type of physics model deals with mechanisms. They are used to see how quickly mechanisms move, and how they are going to move based on what kind of springs and or lubricants are used, or what the friction on the surface would look like.

Such models are generally called kinematic models. For instance, it would be used to see how a different spring in an M16 rifle would affect the rate of fire. “All these models are essentially just fancy ways of calculating whether something is going to work properly or not,” Carlucci said. “Years ago it used to be done by hand calculation. Now we can do it with computers.”

Although physics models help with crunching numbers, Carlucci said the validation is usually left up to the engineer to make sure that they are confident in their models and, it shows up in tests of their systems.

While engineers may be able to predict an outcome, or how something should work in theory, their conclusions are not always accurate.

“We have models that predict burning of propellants,” Carlucci said. “Those are about average on how good they are. Sometimes they work, sometimes they don’t work quite as well. We have very poor models on ignition,” Carlucci said, adding that ignition is very complex. “So we have to guess about that, and when we guess we generally use data that we gather from a test and feed it into the model.

“An example of this would be the ignition in the ERCA (Extended Range Cannon Artillery) weapons system where we use physical simulators to feed more detailed ignition models. This prediction is important because getting it right saves a lot of test costs and time and allows us to field a safe system.”

Carlucci said models that predict metal failure are usually excellent given that the right material properties are used. “Nonetheless they are validated through a Lab test or actual gun firing,” he said. “Normally when we are doing a model of an entire projectile system or any entire gun system, we validate it by going to the proving grounds and putting strain gauges or accelerometers or some other device on the system when we test it.

“We compare it back to the model and see that it matches. If it doesn’t match we make modifications to the model by asking ourselves ‘What did we assume that was wrong?’ ‘What was incorrect in the model?’ The model could be wrong because it has the wrong material properties or behavior. The model could be wrong because one of the assumptions such as boundary conditions we put into the model were incorrect. Once we correct them, the models usually match fairly well to test results. That is considered, ‘validation.’”

Modeling and simulation is a vast field. While Carlucci’s expertise is the physics models, there are other models such as operational models, logistical models, lethality models and others.

“The holy grail is to take these very detailed physics models and combine them into sort of operational models. It’s like the engineers are using the physics models as nuts and bolts. They take the nuts and bolts, aggregate them, and say, ‘Here is what an Army officer can look at from an actionable standpoint.’”

Social Sharing