At Dugway Proving Ground, the innovative SPITFIRE fixture is bagging two birds with one stone. While being validated for an upcoming test, it is also being used to ensure a new lot of glove box glove replacements are durable enough for use in the Chemical Test Division.

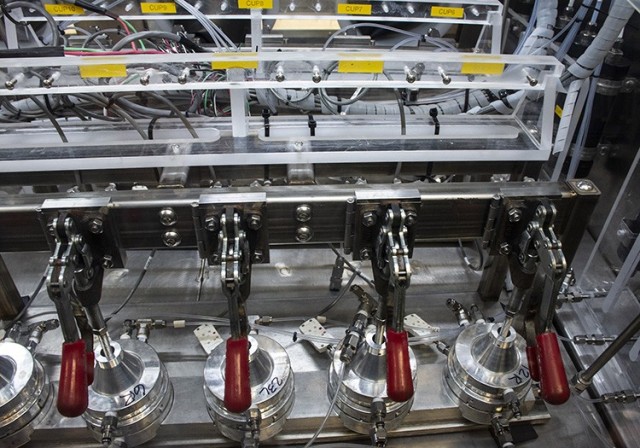

SPITFIRE (Swatch Permeation Test Fixture, Reengineered) is a recent fixture created for reduced cost of operation and easier setup when challenging samples of material (called “swatches”) and how well the material protects its wearer from chemical agents and hazards. In the past, the AVLAG (Aerosol Vapor Liquid Assessment Group) was used to challenge swatches with agent, requiring tedious assembly with multiple bolts in a permanent chamber. SPITFIRE is within a wheeled glovebox chamber and may be moved from one lab to another before testing begins. It retains similar components to AVLAG, but the tension of a single clamp holds all pieces together tightly. In both systems, sandwiched within two hollow-centered components, is the test swatch. Agent or simulant is disseminated onto the swatch, and testing begins.

“The Air Force has scheduled a test of material, to contaminate it with X-amount of chemical agent vapor,” explained Project Scientist Aaron Rogers of West Desert Test Center. “Then, the material will be monitored as the agent offgases from the material. The Air Force wants to know if the levels get so low that it’s possible to reuse the protective suit after a certain period of off-gassing time.” But before this test, SPITFIRE must be verified and validated – a series of steps to determine if a system or component meets all requirements. To that end, the material used in glovebox gloves also faces testing. “We’re verifying gloves for lab use,” Rogers said. “The material needs to last a certain amount of time before it can be considered safe for use in the lab. In this case, however, we’re actually letting it go long enough that we see a breakthrough of agent to the other side of the swatch.” Knowing the point of breakthrough will indicate when replacement is due. Eight glove samples will be challenged with chemical agent, and two additional samples serve as controls. Rogers noted that engineers and testers are already designing an improved SPITFIRE 2.0, which will be quite different from the current model. At an Army post where innovation and efficiency are commonplace, one has to wonder how many birds SPITFIRE 2.0 will bag with one stone.

Social Sharing