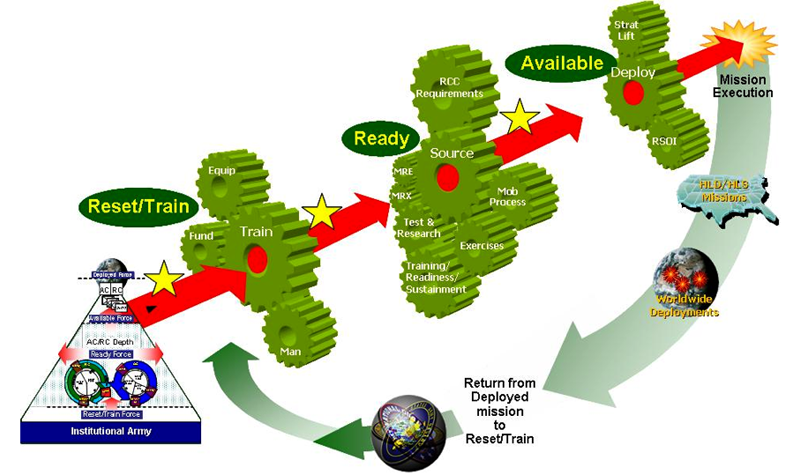

• Reset/Train Force Pool: Units enter the Reset/Train Force Pool after returning from a deployment. Their mission is to rec... VIEW ORIGINAL

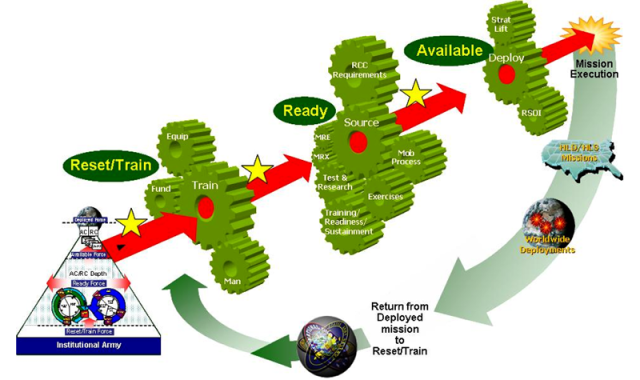

Like any high-performance power source, the Army needs a smooth-running transmission to apply force on the ground.

Constantly in motion, synchronized with other activities, and operating largely unseen, Army Sustainment Command is a key part of the Army Force Generation Process.

By design, ASC is Army Materiel Command's integrator for ARFORGEN. Our global network of Army Field Support Brigades and Battalions, Logistics Support Elements, Brigade Logistics Support Teams and task-oriented teams are all linked to ASC Headquarters at Rock Island Arsenal, Ill.

From ASC's Field Support Directorate, especially the Distribution Management Center, we are connecting the dots from battlefields and training centers all the way back to sources of supply and repair, and beyond to acquisition and technology activities.

In his presentations to visiting officials, Maj. Gen. Robert Radin, ASC's commanding general, puts ARFORGEN atop the list of the command's mission sets. He points out ASC is providing logistics support at every stage of the process, from pre-deployment to deployment and sustainment, and on to redeployment and home-station Reset.

Several programs feature prominently in ASC's ARFORGEN effort.

Left-behind equipment, as the name implies, is that which deploying units do not take with them. When a Stateside unit moves out, ASC moves in, taking LBE onto our books, then seeing to its maintenance and storage. Not only does this free deploying units of the need to leave people behind to attend to the gear, it ensures a high state of materiel readiness on the units' return. In Europe, ASC shares management with U.S. Army - Europe/7th Army.

Field-level Reset is the massive effort to ensure battle-weary equipment is restored to operational capability. Through our work-loading conferences, ASC provides coordinated recommendations to AMC's life-cycle management commands and workload across the installation repair activities and special Field-Level Repair Centers within our maintenance enterprise. In addition, we work closely with the LCMCs to synchronize special repair teams with redeploying units.

Effective training is key to combat effectiveness. For its part, ASC plays an active role in managing pre-deployment training equipment. In coordination with Army Forces Command, ASC maintains and issues PDTE at training centers, saving the time and expense of transportation, while maximizing training opportunities for troops.

All of this, and more, is tied to what Army officials call Institutional Adaptation, the next stage in the Army's ongoing transformation. Its goals, according to the June 3 edition of the Army's "Stand-To!" bulletin, are:

Aca,!Ac Improve Army Force Generation (ARFORGEN)

Aca,!Ac Adopt an enterprise approach to strategic decision-making

Aca,!Ac Reform the requirements and resource processes.

Aca,!Ac

"By organizing around the Army's core process, ARFORGEN, Institutional Adaptation enhances the Army's versatility in response to a complex strategic environment. It isn't a change to organizational structure but is instead a drive to improve collaboration, synchronization and integration across the entire force. Improved cooperation will yield better decisions faster and lead to increased predictability and reduced turbulence.

"To put plans in action, the Army has incorporated an enterprise approach to decision-making. As a result, the Generating Force has functionally aligned into four core enterprises (CEs) aligned around the inputs to the ARFORGEN process (Readiness, Human Capital, Materiel, Services and Infrastructure).

"The Materiel CE is adjusting its processes to provide the Army's senior leadership with the most accurate information for timely and sound decision making to optimize logistical support to the warfighter," according to the "Stand-To!" article.

As a key component of the Materiel Enterprise, ASC is aimed directly at ARFORGEN.

Any mechanic or driving enthusiast will tell you that a smooth transmission - like that depicted in the ARFORGEN illustration - needs good synchros to put power on the pavement.

So it is with ASC. With global reach, expertise and enthusiasm, we keep the gearbox humming, synchronizing acquisition, logistics and technology capabilities, matching materiel to missions.

In plain talk, it looks just like a modern military operation. ASC's field units are the scouts, working alongside training and combat formations, observing and reporting. Working their way up the chain, the scouting reports are combined and assessed, then delivered to the operations center for action.

The Distribution Management Center, located deep in the massive Building 350 at Rock Island Arsenal, is akin to the ops center. From the DMC, all the capabilities of the Materiel Enterprise can be brought to bear on the target.

In the Materiel Enterprise, the DMC adds value by providing centralization, standardization and stabilization for materiel management in CONUS.

The DMC's mission statement spells out the objectives: Provide readiness management for active-duty Army forces in the continental United States, Alaska and Hawaii by serving as the single integrator for field-level Reset and left-behind equipment in support of ARFORGEN.

To make it happen, the DMC establishes relationships that vary from full partnering, to service provider, to training assistance to supported forces. Organized along functional lines, the DMC merges supply, maintenance, funding, contract management, data support and mobility capabilities to deliver solutions.

The DMC's individual tasks are numerous and far-reaching:

Aca,!Ac Single Interface for the synchronization and integration of logistical functions among tactical units, Forces Command, Installation Management Command, the Logistics Support Activity, and AMC's life-cycle management commands.

Aca,!Ac Supervise 15 geographically dispersed Distribution Management Teams responsible for regional materiel and readiness management support throughout CONUS, Hawaii and Alaska.

Aca,!Ac Develop strategic level logistics processes and procedures supportive of ARFORGEN (Reset, LBE, PDTE).

Aca,!Ac Provide supply management support to CONUS, including oversight responsibility for 153 Supply Support Activities.

Aca,!Ac Provide subject-matter expertise to: the Army Integrated Action Group.

Aca,!Ac Help mold the Logistics Information Warehouse into a Logistics Common Operating Picture by providing SME to LOGSA on the development and implementation of Army-wide tools for Reset, maintenance work loading, SSA performance, retrograde, etc.

Aca,!Ac Facilitate materiel management training for Sustainment Brigade Soldiers.

The DMC's got a big job to do - one that's evolving as our transforming Army at war creates new demands. The same can be said throughout the ASC enterprise, "On the Line" from its most far-flung outpost in Afghanistan to the Headquarters.

Social Sharing