Aberdeen Proving Ground, MD -- A select group of military and civilian subject matter experts well-versed in additive manufacturing, specifically 3D printing, gathered at the U.S. Army Combat Capabilities Development Command (CCDC) Chemical Biological Center to assess five 3D printers for the Army’s long-term use.

“The machine selected will be fielded in the next 20 Metal Working Machine Shop Sets (MWMSS) to make replacement parts on the fly as needed,” explained Brad Ruprecht, additive manufacturing subject matter expert at the Center.

The MWMSS is part of the Mobile Maintenance Equipment Systems that provides a holistic maintenance and repair capability to the warfighter. The 3D printers will be used in an expeditionary environment to augment, and in some cases replace, the supply chain for the Army, Ruprecht said.

Ruprecht gave an overview of the assessment process and explained how the team was hand-picked by the U.S. Army’s Capability Development Integration Directorate.

“A lot of these guys have years of experience with 3D printing, exploring the new world of additive manufacturing as part of their job but also as a hobby,” said Adrian Bailey, who assembled the team on behalf of the Army. “There are also a few guys that have very little experience with additive manufacturing but play critical roles that necessitated their involvement.”

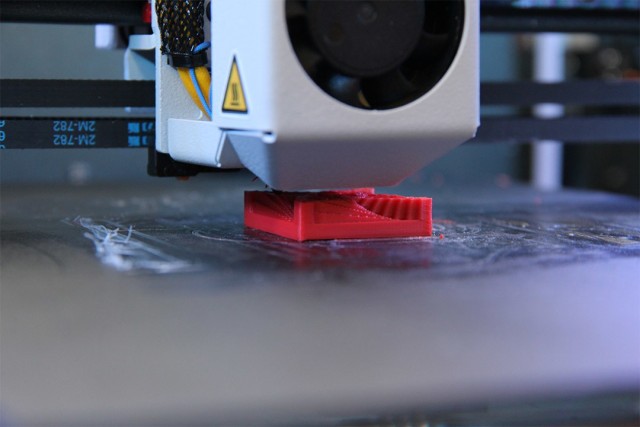

With introductions and initial questions complete, it was time to put each printer to a test by having each one print the same design. The test print was designed by CW2 Andres Arango who made sure the design really put each printer through its paces.

“Designing a cube is one thing but we’re looking for precision of the printers, among other things,” said Arango. “I incorporated a staircase design into the center of the cube to complicate things. A good printer will more accurately build the entire shape where on a lesser printer, the stairs might come out more like a blob.”

During the assessment, each person chose a printer to run. They used the software and the hardware to get the full feel for how the printer performed from start to finish.

Once the printers completed the job, the team assessed each printer based on the final product to determine which one performed the best. Beyond that, they will assess each printer on a host of other qualities, including physical size, weight, software compatibility and cost, to determine which printer they will recommend to Army leadership.

Army leadership will consider the team’s assessment and ultimately choose the printer that best meets the needs of the warfighter. Once the printer is selected, it will be used to teach Soldiers at the Allied Trades School House at Fort Lee, Virginia.

**********

Social Sharing