For a center that specializes in creating military training devices, to include unexploded ordnances and improvised explosive devices, the facility’s latest production might come as a surprise.

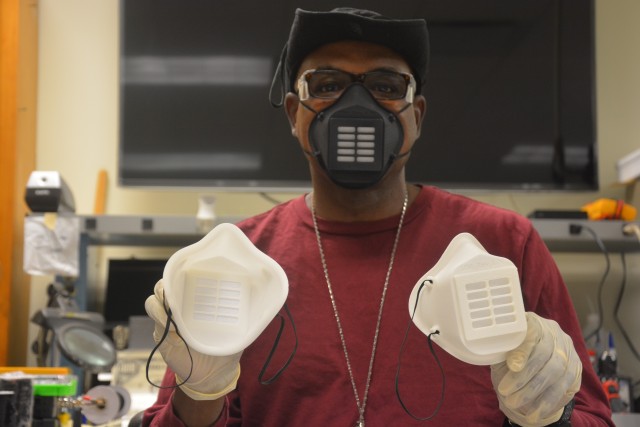

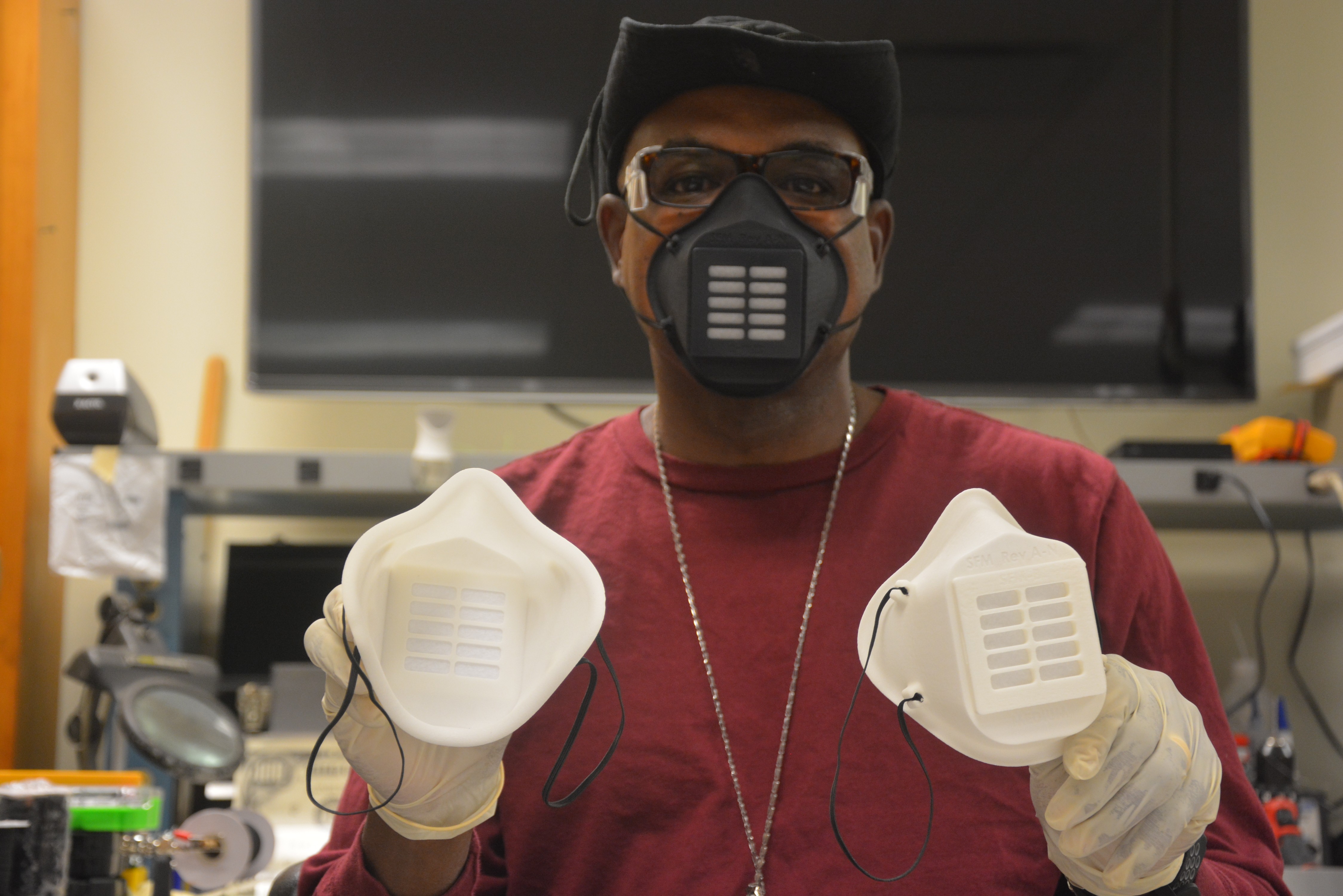

Like many people, Brian Clayson and his coworkers found themselves having to purchase masks during the onset of the COVID-19 pandemic. Surrounded by state-of-the-art technology, namely 3D printing capabilities, Clayson, training support officer with Fort Gordon’s Training Support Center Division (TSCD), said a thought occurred to him.

“I was like, ‘Why can’t we just make 3D-printed masks?’”

Clayson and his staff began researching how to make masks and reached out to the company that they got the center’s 3D printer from, which got the process moving.

“They had a CAD/CAM file already on file they could give out to make the masks, so they sent it out to us, and we first did a prototype for the mask and for the face shield,” Clayson explained. “We printed it out and took it up to the garrison commander to get his approval so we could go forward with it.”

Despite receiving the GC’s approval, the prototypes had to go through several other commands, to include U.S. Army Medical Research and Development Command (USAMRDC) out of Fort Detrick, Maryland, before finally being approved.

“They’re a part of the COVID-19 Task Force for Department of Defense,” Clayson said. “Within 24 hours, they had all the legal verbiage in there and everything else that we needed.”

Clayson’s team followed the command’s guidance and began churning out face masks and shields.

Aside from cleaning, attaching straps and packing, the process for making each mask is digital and takes 24 hours per 40 masks, whereas prototypes take one-third of the time.

Emphasizing how important it is to get each prototype perfect before creating an actual mask, Clayson said that the slightest flaw in a prototype forces them to redo the process.

“When you’re scaling these prototypes, you have to watch because when you’re making it larger so it fits differently, you have to change the whole interior on all of the shapes in it,” Clayson said. “If you mess up on your prototype, you come back and redo it and redo it until you get it right.”

Each mask comes with 21 pre-cut filters, adjustable straps, and seven pages of instructions that include how to properly wear, clean and store one’s mask.

Clayson said although the masks are effective and come with the lowest micron filter they could find, they are not suitable for those coming in direct contact with COVID-19 patients.

“This is not an N-95 mask,” Clayson said. “It does filter down to 5 microns, but it just prevents you from coughing on people and people coughing on you.”

To date, the TSCD has produced more than 1,000 masks and 150 face shields made of plexiglass.

Craig Larsen, Directorate of Family, Morale, Welfare and Recreation director, received about 250 of the masks, which he distributed to critical childcare workers, his Technical Services Team, and staff members who are cleaning facilities in preparation for reopening. Larsen said he was impressed by the masks and appreciated the time and effort the TSCD put into producing them.

“The masks are very durable, easily cleaned and filter far more than typical cloth masks,” Larsen said.

Clayson that while it is nice hearing they may be making a positive difference, he insists that he and his team are not doing anything spectacular.

“We’re just doing our job,” Clayson said. “And it’s good because it gets everybody back into work and excited about it.”

Social Sharing