ROCK ISLAND ARSENAL, Ill. – Soldiers from the 4th Quartermaster Theater Aerial Delivery Company, stationed at Joint Base Elmendorf-Richardson, Alaska, recently turned a routine mission into something special.

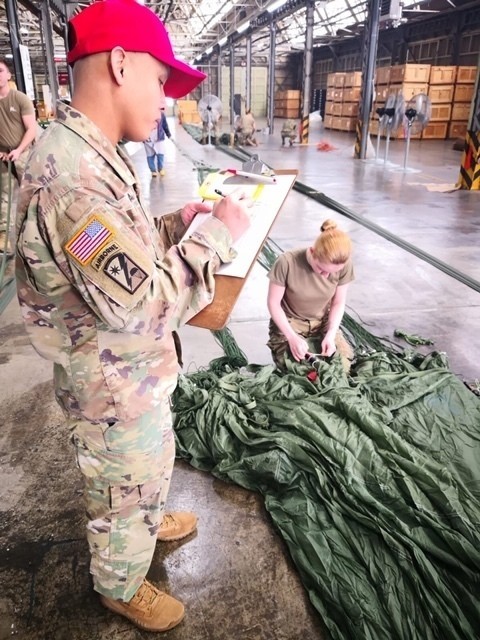

The parachute riggers recently spent 10 weeks at Sagami General Depot in Japan, conducting an annual Care Of Supplies In Storage mission where they assisted the Army Field Support Battalion-Northeast Asia’s Japan Support Team with the inspection, repair and repacking of more than 14,000 aerial delivery system items.

Parachutes large and small were unpacked, inspected for defects such as rips or tears, then repaired as needed, repacked and recertified. The work is repetitive and can be monotonous, but the Soldiers know how important their efforts are.

“We need to get this one done right because people’s lives depend on us,” said Staff Sgt. Angelito Froa, who was the non-commissioned officer in charge of the COSIS mission. “It's really important stuff.”

The team was so efficient, they finished up their mission three days early. Instead of kicking back, however, the riggers kicked things up a notch by deploying their secret weapon – their sewing skills. The timing was perfect as COVID-19 was ramping up in Japan and elsewhere, so the riggers took the opportunity to churn out high quality, fabric face masks for U.S. Army Japan.

“We provide support for the warfighter during contingency operations and we maintain all the aerial delivery equipment that is part of the Army’s Prepositioned Stocks in Korea and Japan,” said, Chief Warrant Officer 4 Brian Perinon, master air drop systems technician, JST. “The 4th QM Co. did a great job. Not only did they finish early, but they took those extra couple of days and applied their specialized sewing skills to produce face masks for the command here. We were lucky to have their particular talents at such an opportune time.”

The riggers produced 95 high-quality face masks in the three days.

“We finished ahead of schedule and due to the global pandemic, we went from sewing parachutes to sewing and fabricating face masks. If there is one thing that we really know how to do, it’s to operate a sewing machine,” said Chief Warrant Officer 2 Mervin Terre, senior airdrop system technician, 4th QM Co. “It was meaningful to be able to utilize our skillsets to help flatten the curve while contributing to the local command during this worldwide pandemic.”

Before leaving, the team patterned a mask template, prepped enough materials for the fabrication of approximately 200 masks, and provided a block of instruction teaching local workers how to sew the masks on their own. The Japanese Master Labor Contractors from AFSBn-NEA have produced more than 1,700 of the coveted masks for USFJ.

“I really learned a lot. It was great working with the civilians from the battalion. They were quick every time we would ask them a question, or we needed something, they would have it, ready to go right away,” said Spec. Michael McConville, parachute rigger, 4th QM Co. “This was a really good experience and I hope I have a chance to come back some day.”

AFSBn-NEA, headquartered at Camp Carroll, South Korea, falls under the 403rd Army Field Support Brigade, located in Daegu, South Korea. The 403rd AFSB is a subordinate unit of the U.S. Army Sustainment Command headquartered at Rock Island Arsenal, Illinois. ASC, the control hub for global Army logistics, falls under the U.S. Army Materiel Command headquartered at Redstone Arsenal, Alabama. AMC, a four-star command, delivers logistics, sustainment and materiel readiness from the installation to the forward tactical edge to ensure globally dominant land force capabilities.

Social Sharing