A program that modernizes Black Hawk helicopters maximizes Corpus Christi Army Depot’s capabilities as part of a winning readiness strategy for U.S. Army aviation.

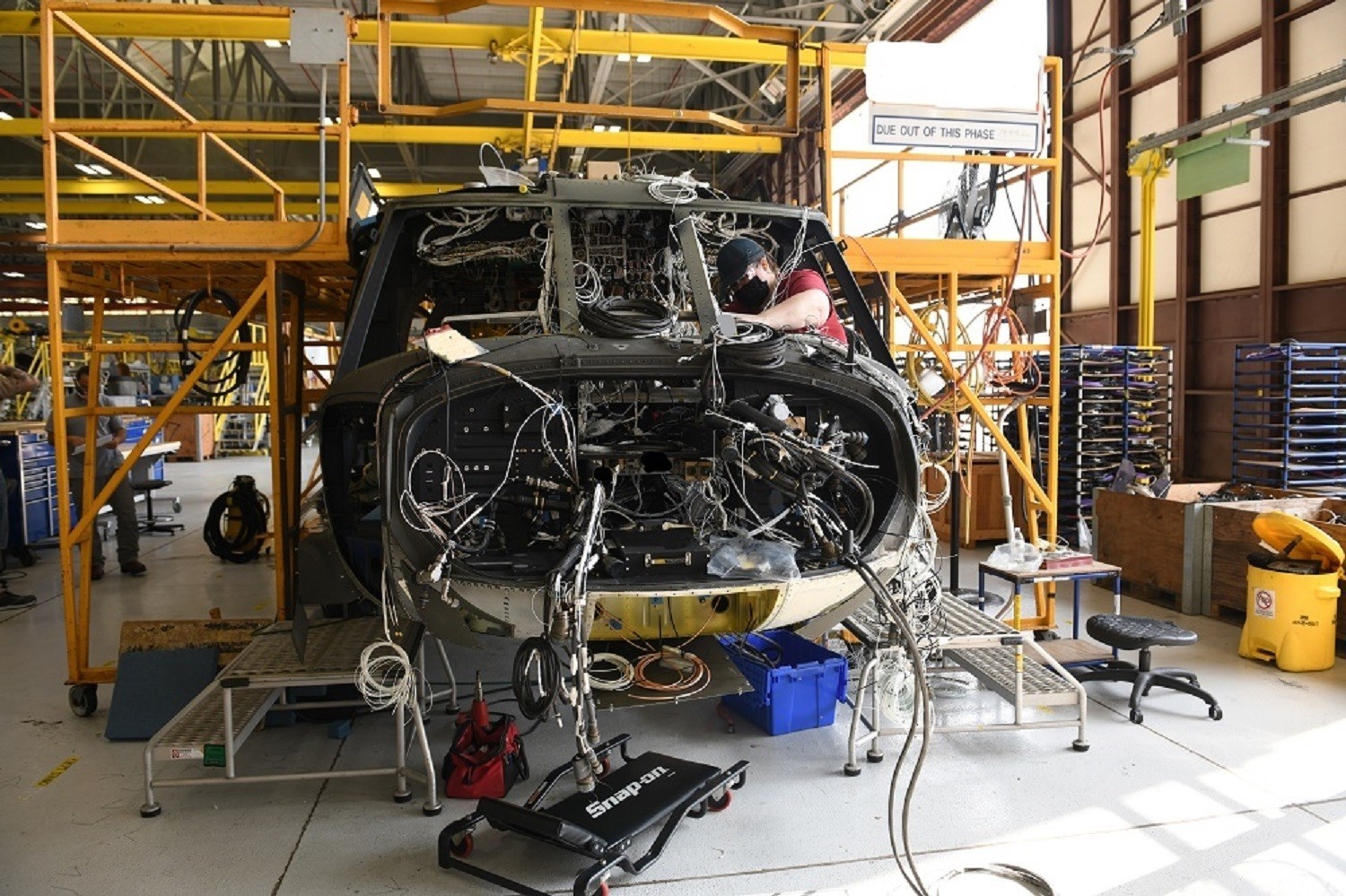

Skilled artisans and technical experts at Corpus Christi Army Depot are upgrading UH-60 Black Hawk helicopters, leveraging the Army’s investment in an enduring fleet of aircraft slated to continue service for decades to come. The upgraded aircraft are known as UH-60 “Victor” models. The Victor is a transformed UH-60 “Lima” model helicopter with a glass, digital cockpit that replaces an older analog system.

As the Army focuses on modernizing its aviation fleet through its Future Vertical Lift program, the Black Hawk – known as the workhorse of Army aviation – has critical continuing roles in air assault, medical evacuation, combat stability, and support and special operations.

“The Black Hawk has more than 40 years of proven dependability and we will continue to rely on our enduring fleet for years to come,” said U.S. Army Aviation and Missile Command Commander Maj. Gen. Todd Royar. “This upgraded Victor model benefits Soldiers, pilots and the Army while showcasing the capabilities of our Organic Industrial Base.”

Corpus Christi Army Depot is among 26 facilities the Army calls its Organic Industrial Base, which includes maintenance depots, manufacturing arsenals and ammunition plants. The Organic Industrial Base has a role in maintaining military readiness and retains the capacity to surge in support of national security.

Rather than turning to industry for the modernization work, Corpus Christi Army Depot was selected because of its established capabilities. The depot’s workforce is already well-versed in providing what is known as the L-to-L recap – which takes the aging UH-60 Lima models through a program that refreshes their technology and systems, extending the life of the aircraft.

“Our workforce has decades of consistent performance delivering like-new airframes and components back to our Nation,” said Corpus Christi Army Depot Commander Col. Gail Atkins. “We are humbled and honored to be chosen by the Army as the provider of the UH60V fleet.”

The technical transition that produces a Victor model culminates a years’ long collaborative process between Army researchers and industry. That cooperative effort comes to life when the aircraft moves through the various “gates” at the depot.

“Corpus Christi Army Depot has been an invaluable partner on the Victor program,” said Program Executive Office – Aviation UH-60V Program Manager Lt. Col. Dan Thetford. “I have personally toured their main production line, back shops, and quality-control efforts; their ongoing contribution to the program will be critical in providing the best possible aircraft to our Army air crews."

The first two Victor model aircraft are nearing completion and should be final flight tested by September said Corpus Christi Army Depot Operations Manager Rod Benson. During the Low Rate Initial Production, the depot will produce 72 aircraft over five years. The Victor model Black Hawks will go to Army National Guard units, with the first unit expected to be fully equipped in Fiscal Year 2021. All told, the depot is slated to transition hundreds of Lima models to Victor models.

From concept to prototypes to test flights, the result is a government-owned Technical Data Package installed by the Depot workforce, extending the life of the airframe while improving commonalities with the Army’s Black Hawk fleet.

The government-owned technical package maximizes competition among vendors. Using an open-system architecture approach means the software design is not dependent on proprietary systems, making it easier to add or swap components and facilitate faster future upgrades.

“The UH-60 Victor program upgrades the Lima model with a digital suite that streamlines the cockpit for increased situational awareness with an enhanced cockpit management system,” said Benson. “Features include a moving map, enhanced messaging between pilots and a state-of-the-art navigation system.”

The featured upgrades in the UH-60V also include common functionality with the Mike model of the UH-60 – the most modern Black Hawk in the Army’s fleet. The resulting commonality translates into shared avionics and streamlined pilot training, improving both efficiency and cost.

“The Victor leverages the UH-60 Lima airframe by allowing for an affordable, relevant upgrade option with a Pilot Vehicle Interface that is comparable to the UH-60M. The modernization will improve the aviation community by streamlining the training requirements for pilots on both the Black Hawk Mike and Victor aircraft,” said Benson.

Social Sharing