Being prepared for COVID-19 at Medical Department Activity-Alaska requires trained medical personnel to care for patients. To treat those patients safely while protecting staff and other patients, it also required facility changes and logistical support.

The initial focus for the facilities staff was setting up a tent outside the Bassett Army Community Hospital emergency room entrance to keep potential COVID-19 patients isolated while being screened.

“This turned out to be a real team building experience,” said Tim Steele, deputy chief, facilities management branch for MEDDAC-AK. “We had five brand new team members and with a deadline fast approaching we found ourselves putting the tent up in the middle of a snowstorm with 35 miles an hour winds.”

With the screening tent up and operational, the team installed high efficiency particulate air, or HEPA filters, and converted three rooms on the multi-service unit to negative pressure. This modification allows air to filter into the room but not escape, preventing airborne contagious diseases such as COVID-19 from contaminating other parts of the unit. These three additional rooms brought the total of negative pressure rooms in the facility to nine.

Also on the MSU, the team built temporary walls to provide an extra layer of safety for staff members working the unit.

“The tent and the MSU project pushed us out of our comfort zone,” said Steele. “There was a lot of research and collaboration with infection control, industrial hygiene and public health to make sure we were following guidelines and best practices to keep our patients and staff safe.”

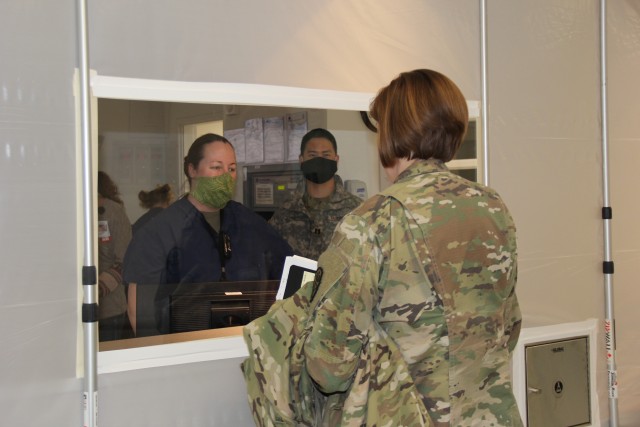

Another layer of protection for everyone entering the building was the addition of plexiglass and social distancing lines.

“We installed plexiglass ‘sneeze guards’ in all our check-in areas to create a barrier between the patient and the staff member in all our facilities,” said Steele.

While facilities was working to prepare MEDDAC-AK buildings, logistics worked to ensure the organization had enough personal protective equipment, supplies and medical maintenance contracts in place.

Like the rest of the world, MEDDAC-AK wanted to ensure there were proper levels of PPE available to provide care safely, said Maj. Michael Cooper, MEDDAC-AK chief of logistics. “N95 masks, surgical masks, hand sanitizer, thermometers and gloves were all in high-demand.”

“There was a lot of education that had to take place with our medical staff to prevent panic ordering from different sections,” said Cooper. “We had to change the mindset from worst-case scenario stockpiling to only ordering smaller quantities needed for a week or a two at a time, in order for our orders to not be immediately cancelled by the vendor.”

According to Cooper, one of the biggest successes in the logistics department was the work done by chief of Installation Medical Supply Activity, Mrs. Susan Turley and her staff at the IMSA. “She and her team worked through the supply chain to find the necessary PPE,” said Cooper. “They found alternate vendors and navigated through ordering constraints in smaller distribution channels.”

In addition to using vendors to get adequate PPE, logistics also collaborated with industrial hygiene and infection control to educate staff on the conservation of PPE using best practices from the Centers for Disease Control and Prevention.

The medical maintenance side of logistics moved quickly to procure additional licensing for the central viewing monitoring system on the MSU.

“The license was for 16 beds but needed to increase to 22,” said Cooper. “In the event we had all 22 of the rooms occupied, each patient could be monitored from the nurse’s station with the central viewing system.”

Housekeeping staff continue to be vital part to the logistics team by ensuring MEDDAC-AK facilities are prepared and safe. Additional education on COVID-19 helped to calm some fears by housekeeping team members and best practices from the CDC set into place additional measures, mostly in the way of increasing the number of times deep cleaning takes place daily.

Steele and Cooper both believe MEDDAC-AK is ready for COVID-19 patients.

“It’s taken time and a lot of teamwork, but we’re ready,” said Cooper.

Social Sharing