On Jan. 20, 2020, the World Health Organization declared a public health emergency of international concern due to COVID-19. On Jan. 31, 2020, the Secretary of Health and Human Services declared a public health emergency in the United States. In response to these declarations, the Center for Disease Control and Prevention has identified precautions citizens should take to stay healthy, to include covering mouth and nose with a cloth face cover.

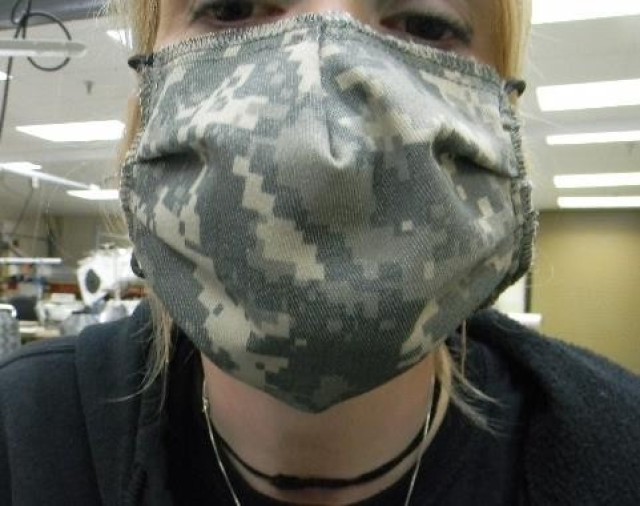

In a memo signed April 5, 2020, the U.S. Secretary of Defense, Mr. Mark Esper, directed all individuals on Department of Defense property, installations and facilities to wear a cloth face covering when they cannot maintain six feet of social distance in public areas or work centers. Within 48 hours, Pine Bluff Arsenal, a Joint Munitions Command installation, responded by producing a face mask to protect military personnel, Civilian employees, contractors and all other individuals on DoD property.

PBA, the Center of Industrial and Technical Excellence for Smoke Ammunition and Chemical-Biological Defense, already has an existing cut-sew-seam mission in support of Joint Program Executive Office for Chemical, Biological, Radiological and Nuclear Defense, sewing Chemical Patient Protective Wrap, Integrated Footwear System and Neck-Dams. Using existing equipment and rapid procurement of needed supplies, PBA subject matter experts and textile industrial workers anticipate producing a large quantity of face masks to support this DoD directive.

The Army and Joint Munitions Command are conducting a change of mission to protect the force and the nation. With this new mission, the Army continues to support global operations and combat operations, while fighting COVID-19. The Army continues to assess how best to protect Soldiers, Civilians and their Families; maintain force readiness to meet global challenges; and provide support to the FEMA-lead national COVID-19 response. “The design and production of face masks at PBA is just one way PBA and JMC are supporting DoD’s COVID-19 efforts,” said Col. Luis Ortiz, commander of PBA.

Force health protection is the Army’s top priority and Army senior leaders are urging everyone to adhere to the latest CDC guidelines to prevent the spread of the virus. The PBA team, in coordination with leadership at JMC and higher-headquarters, Army Materiel Command, is rapidly working to determine production requirements, funding sources and how best to distribute masks to help protect citizens against airborne particulate materials.

Social Sharing