The hallmarks of today's Army Depot leads to readiness

Story and photos by Della Adame

Corpus Christi Army Depot Public Affairs

Corpus Christi Army Depot, Texas --- The Corpus Christi Army Depot (CCAD) continues to grow and its quest for talent continues to transform how to acquire, develop, and retain our most valuable asset – our people.

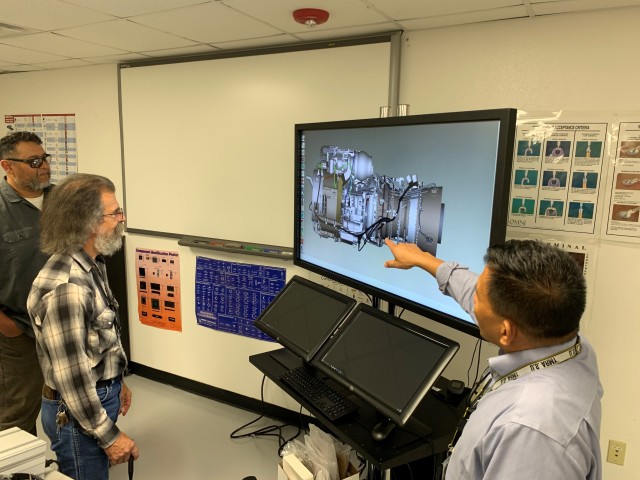

Bryan McMillan, training specialist lead for the Workforce Development Division (WDD), led the effort to bring a special training system to CCAD.

The system allows employees to visualize the inner workings of an actual helicopter engine and pull it apart…virtually. Yes, a virtual engine, think Iron Man Tony Stark style of tech.

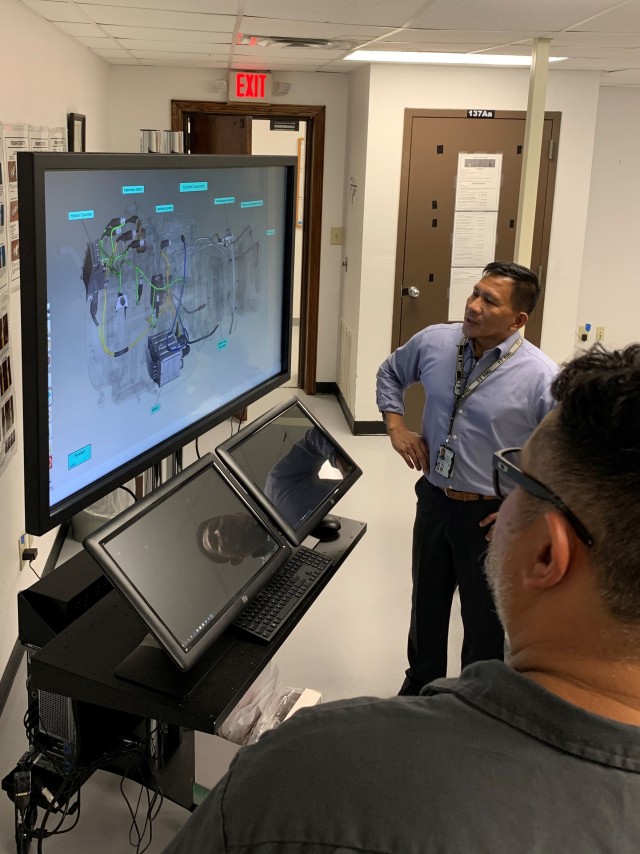

“We will be able to utilize artisans who are subject matter experts, who passionately serve as adjunct instructors and can answer the technical, complex questions that arise.” said McMillan.

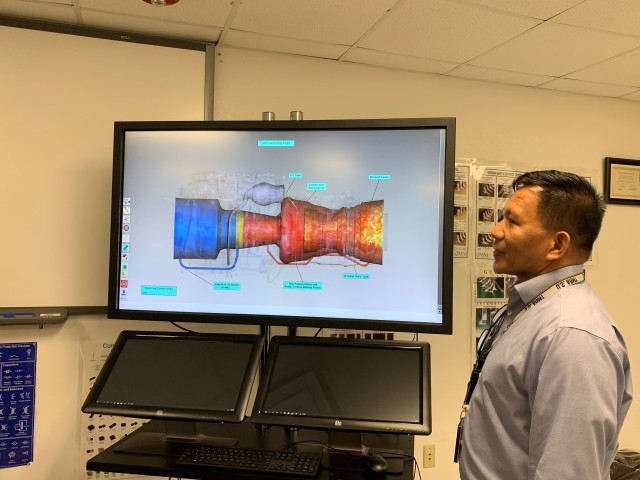

The Virtual Interactive Environment (VIE) platform provides a high definition 3-D compartmentalization capability that allows students (artisans) to visualize the engine or avionics systems.

It’s a virtual drill down into the smallest module or section of the systems. Imagine being able to virtually see what the problem is inside the engine while it is in use.

These virtual training systems caught the attention of McMillan in 2018 during a temporary duty assignment at the Logistics Aviation Readiness Center at Fort Hood, Texas.

This opened the door for a site visit to CCAD by original equipment manufacturer, Logistic Services International, Inc. to present depot leaders and supervisors with a show-and-tell of the capabilities.

Upon seeing the systems in action first-hand, leadership not only wanted the systems, they needed them.

McMillan said, “This is a big win for CCAD and I’m excited to see where this will go, and the impact it will make.”

The systems are stand-alone and do not interface directly with the CCAD network.

Upgrades and revisions come directly from Apache and Blackhawk Program Executive Office located in Huntsville, Alabama.

Each of the systems are comprised of a main 55-inch touch screen and two smaller instructor touch screens.

When all T700 artisans have taken the initial training, intermediate and advanced levels of training will be leveraged and competencies can be managed throughout their careers.

McMillan said, “I call this a "force multiplier" because this system can be utilized as standardized training for the target mass groups, from basic familiarization to advanced levels.”

Brett Todhunter, CCAD Electronics Mechanic, has experience working on this type of system.

“The VIE has the possibility to do great things for the Depot.” said Todhunter. “I see it helping new employees become familiar with different aircraft platforms than they have worked on before.”

WDD is always seeking new innovative technology to train and improve the skill level of the workforce, from the newest employee to the seasoned artisan in the shop. They are committed to providing only the best for the workforce, because the people at CCAD are our strength.

Social Sharing