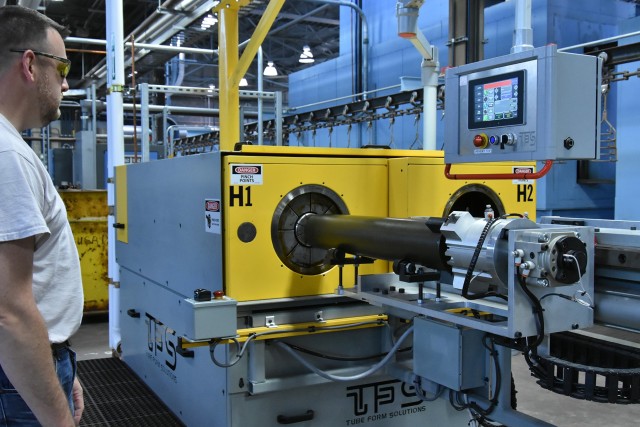

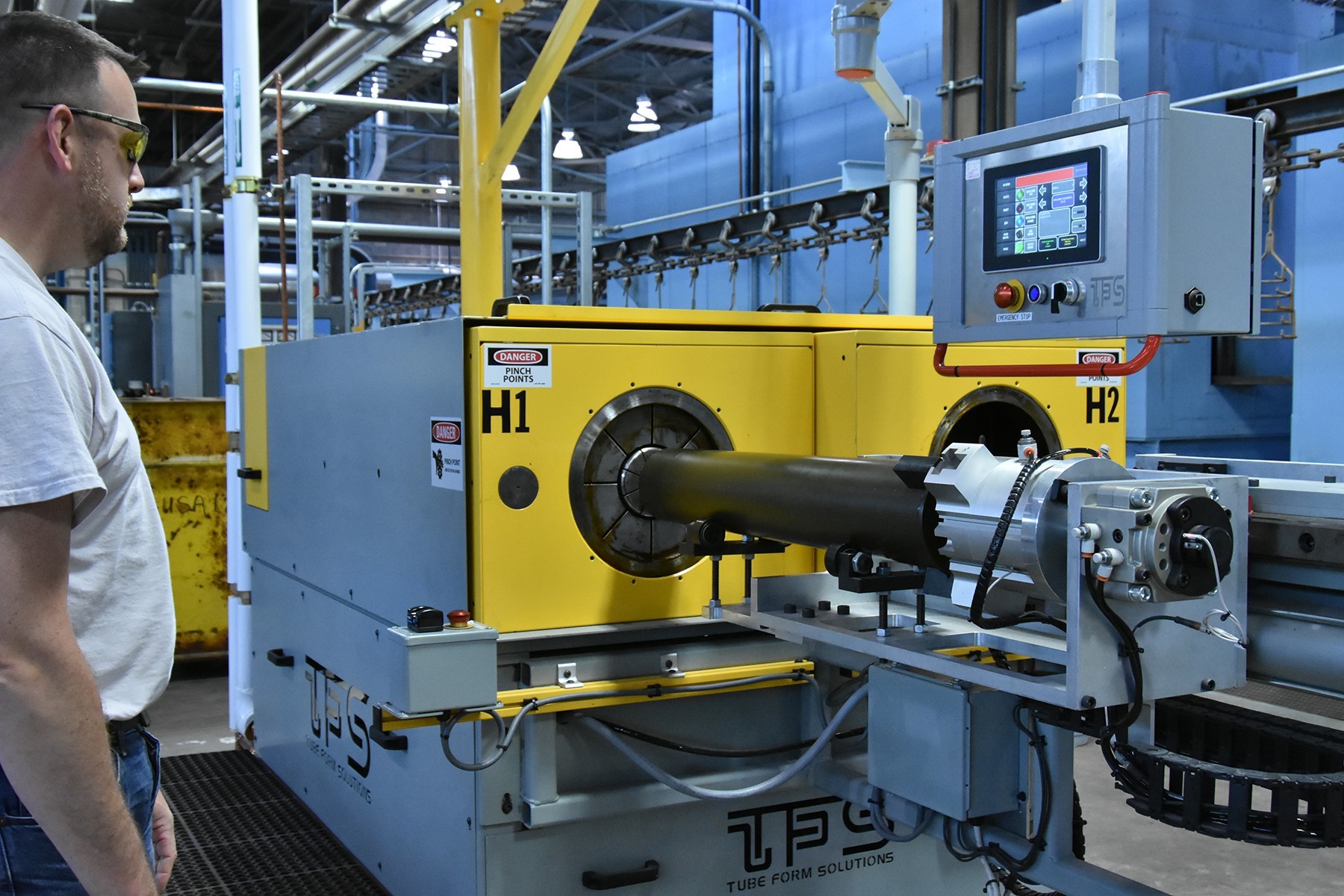

ROCK ISLAND ARSENAL, Ill. – The Quad City Cartridge Case Facility is a state-of-the-art, Army-owned facility, which is capable of producing deep-drawn steel and brass cartridge cases, such as those used with the U.S. Navy’s 5”/54 caliber system and the U.S. Army’s 105mm tank ammunition. The QCCCF also has the capability to produce 40mm to 155mm cartridge cases for all U.S. services. The Joint Munitions Command maintains control and oversight of all production equipment associated with the QCCCF.

In 2005, the Base Realignment and Closure Act relocated equipment from Riverbank Army Ammunition Plant in Riverbank, Calif., to RIA, and in 2011, the QCCCF successfully proved-out equipment on the steel case line. At that point, the Army did not have requirements to produce steel cartridge cases; however, brass cartridge cases were produced from fiscal years 2012 through 2014 to support the U.S. Air Force and foreign military sales to allies.

In 2014, the facility was laid away due to lack of sufficient requirements, and the Joint Manufacturing and Technology Center at RIA performed standby maintenance procedures through 2016.

In fiscal year 2017, the Naval Surface Warfare Center expressed interest in using the QCCCF for research and development efforts, as well as for the production of requirements for 5"/54 caliber (Mk9) steel cartridge cases.

As of June 2019, all equipment within the QCCCF has been reactivated. Currently, the Navy continues to prove-out the equipment with the production of Mk109 (a new version of the Mk9) and Army 105mm tank steel cartridge cases. The Navy plans to complete "first article" testing of the Mk109 and to start production by the third quarter of fiscal year 2020.

This unique teaming arrangement between the Army and Navy, in operation of an Army ammunition facility, demonstrates the Army’s dedication to meet the needs of all services to fulfill not only current demands, but to be postured for future requirements.

In addition, this collaboration keeps the facility operational and retains the employees who know how to operate the equipment, which are significant competencies for both the Army and the Navy. In order to increase capacity to meet any potential surge requirements, additional employees would possibly be hired.

While the Army owns the intellectual property of the QCCCF, NSWC is responsible for maintaining equipment that is used to support Navy production requirements.

But, because the QCCCF is an Army facility, any emerging Army requirements for production of steel cases would take precedence over Navy requirements.

Due to the successful collaboration between Army and Navy, the QCCCF will maintain the ability to produce cartridge cases for the foreseeable future.

Social Sharing