ROCK ISLAND ARSENAL, Ill. - As the Army’s munitions provider, Joint Munitions Command places extraordinary emphasis on explosives safety. As part of its continuous focus on safety, JMC is conducting a four-year, command-wide review of its Explosives Safety Site Plans. This Risk Management process evaluates the locations of current and potential explosives and toxic chemical activities to ensure that mission requirements are met with a minimum risk to personnel, equipment and assets. Such efforts ensure that JMC remains an Army leader in safety.

Diligent safety standards were not always the rule. Prior to 1910, there were no regulations directing where explosives assets could be manufactured, tested or stored in the United States. The approach to this issue changed in 1926 when a series of devastating explosions destroyed nearly 200 buildings at Lake Denmark Naval Ammunition Storage Depot and also caused significant damage at neighboring Picatinny Arsenal. In 1928, the military services adopted the American Table of Distance to decrease the likelihood of future accidents. The newly-formed Armed Forces Explosives Safety Board, later the Department of Defense Explosives Safety Board, took charge, using the ATD to determine safe separation distances. Since then, DDESB and the Services have worked to develop and implement DOD explosives safety criteria that is more restrictive than ATD.

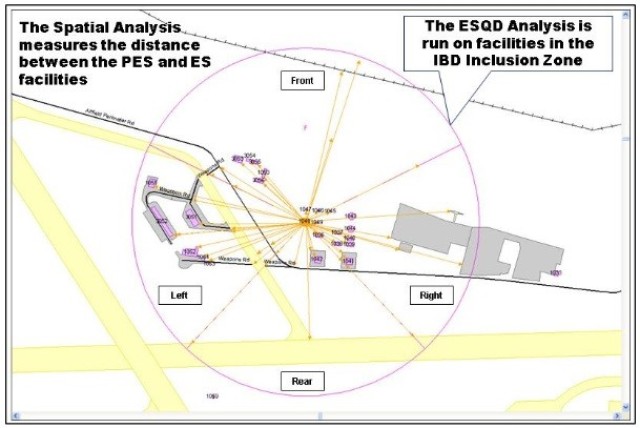

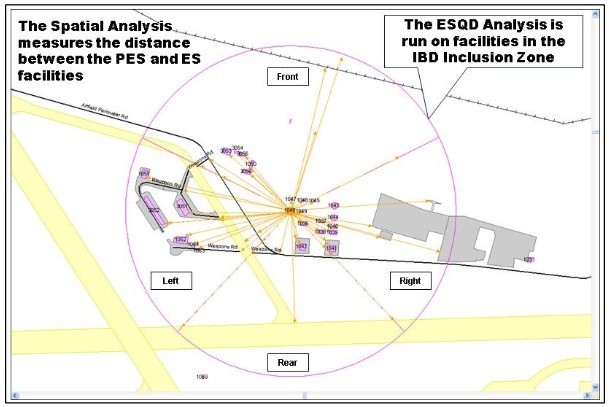

Explosives Safety Site Plans are key to ensuring safe placement of ammunition assets in the modern military. Each ESSP describes the relationship between a Potential Explosion Site or toxic chemical site, Exposed Sites, and personnel, while describing construction specifications and placement of required equipment. An ESSP consists of all information necessary to demonstrate compliance with the explosives safety standards, including relevant maps and drawings of each PES and ES, explosives limits and a glass hazard analysis. Explosives Safety Site software can also help determine Explosives Safety Quantity Distance arcs for explosives storage or handling sites. Once approved, each ESSP identifies limitations and provides a tool for managing risks. Installations then implement controls and changes in accordance with the site plan.

ESSPs help JMC commanders understand the risks associated with ammunition operations and storage in the command’s 14,717 PESs, while assessing the ability of each PES to suppress, and other facilities to resist, explosion effects. By adopting the standards established by over 7,000 ESSPs developed during this review, JMC can maintain the safest possible standards for current and future placement of ammunition and explosives facilities, while ensuring safer conditions for surrounding facilities exposed to PES locations.

Social Sharing