Have you ever wondered about the process it takes to maintain a stockpile of parts to keep the Army in the fight? Not a lot of people have.

Army Materiel Command tasked its subordinate commands, including Tank-automotive and Armaments Command, to synchronize, integrate and maintain operational capabilities for the Army to be prepared to respond to any contingency at any time.

To that end, Mary Isrow, TACOM's Continuous Performance Improvement Deputy Deployment Director, set out to reduce administrative lead times, or ALTs, to improve the speed and efficiency of the procurement process.

These ALTs affect the capabilities of TACOM from entering into contracts to buy the parts needed to help maintain Army readiness.

Isrow brought together subject matter experts from each organization involved as her core team to look at ways to improve contract processing.

"Historically, organizations had only been looking at their portion of the process," she said.

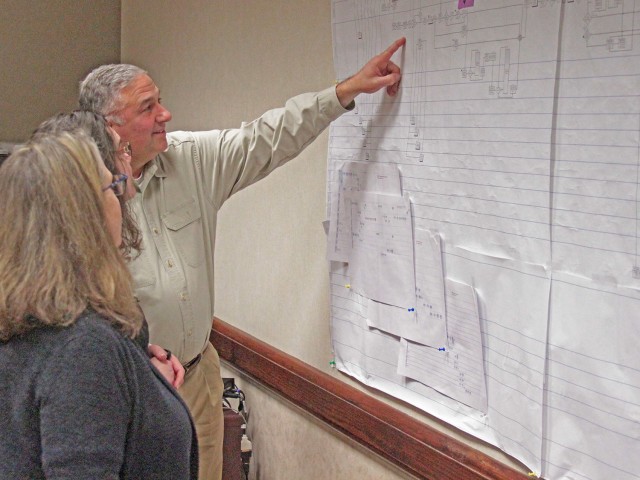

This narrow focus prevented them from seeing how decisions at each level impacted other parts of the organization. Isrow wanted to find a way to present information in a "big picture" sort of way allowing all participants to track the overall process in real time.

Isrow's team documented the entire procurement process from the time a part is ordered until the contract is awarded. They mapped it out in a way that had never been done in the Army before.

This new layout provided a level of detail that allowed the data to be analyzed more effectively.

The previous process didn't allow decision makers to have up-to-date information from all parts of the process for them to adapt to changes rapidly. This delay hindered the organization's capabilities.

The new ALT status report provides a holistic view that provides all team members the ability to see when a procurement contract is ready to be awarded.

"When an organization is able to see and measure itself, it can standardize and control its processes, train and educate its workforce, and start tackling efficiency opportunities," Isrow said.

Isrow briefed Gen. Gus Perna, AMC commanding general, about the new process during his quarterly visit to TACOM Feb. 20.

Perna echoed those sentiments and added, "I do not just want to be enamored by our success, I want to figure out how to see ourselves and make better decisions to processes and execution."

The Integrated Logisitics Support Center plans to educate all of its employees within the next 12 months on the new process mainly through its ILSC Intern Bootcamp.

Also during Perna's visit to TACOM, he was briefed on readiness issues at each of TACOMs arsenals and depots. He stressed that they should be paying more attention to life cycle management and getting quality work done on time.

"The hidden metric is people, as long as we can get people's workload to stay steady, then we will not be forcing workload," he said. "Unplanned workload should be a cause for concern."

It was also pointed out during the briefing by Marion Whicker, ILSC Executive Director, that TACOM has made great improvements in supply chain management.

"We are turning over inventory about every five months," Whicker said, "which means we are buying the right things."

She admitted that she would still like to see more improvement, but overall processes are working.

The depots and arsenals were also reminded of Perna's top priorities for Army readiness and prompted to keep them at the forefront of their efforts. These priorities are to meet readiness requirements for today's needs, be prepared to meet surge requirements in case of contingency, and be prepared to facilitate Army modernization needs.

Perna also recognized some of TACOMs top performers for the quarter, including Nick Hieser, Director of Program and Budget; Stephanie Tice, Deputy Chief of Staff G-6; David Holm, Director Materiel Systems Organization Cost and Systems Analysis; Annette Lozen, Industrial Base Manager; Dave Ellis, Director Human Resources; and Jeff Bohun, Director of Logistics Support Operations.

Social Sharing