ANNISTON ARMY DEPOT, Ala. -- About 200 employees work throughout Anniston Army Depot's industrial shops each night. That number is expected to grow.

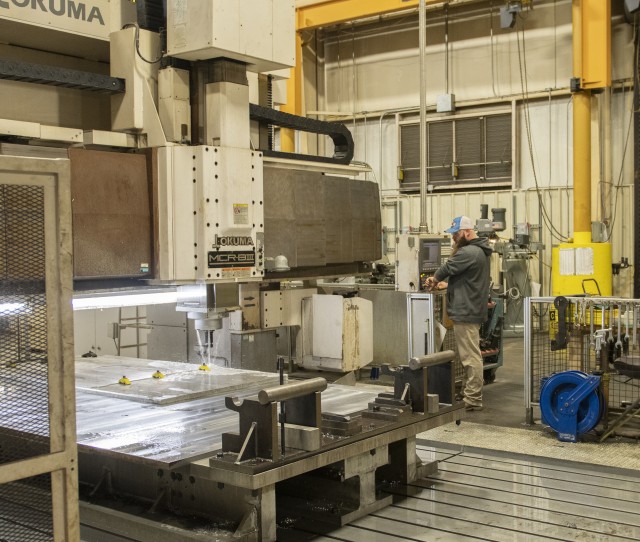

Their workload revolves around disassembly, cleaning, machining and welding - often time consuming processes.

"There's always been a need for machines to run or things to be done at night," said Rohn Bedford, the machinist supervisor for ANAD's night shift.

By performing these duties at night, the disassembled components, newly cleaned parts, created components from the machine shop and so much more are ready and waiting when day shift employees arrive.

"To me, that's the real value of a night shift," said Chris Williams, chief of Production for ANAD's night shift. "We support the day shift - filling in the holes in the line, handling the hot items and making sure everything is ready for day shift."

Production work at night primarily centers on areas with a limited capacity. There are only so many cleaning lines, so, by running them an extra shift, the cleaning area doesn't become a bottleneck for needed parts.

Similarly, the limited machining equipment and welding bays are utilized for longer periods each day.

"The employees out here at night are the unsung heroes of us reaching our production goals," said Williams.

With several production shops running, support and quality personnel also have to be on hand.

Directorate of Public Works' employees keep the equipment running and boiler plant operators keep steam flowing.

The Directorate of Production Management has material expediters and tool and parts attendants working alongside the DP employees and contract employees in the Tool Crib ensuring the correct tools are available.

Safety has a presence at night, as does the Quality Assurance Office.

Chuck Setters, the night shift supervisor for DPM, said support is often the biggest challenge faced on night shift, since many areas of the depot are closed.

"Luckily, I have great support from my supervisor, Jason Childs, and the day shift supervisors in DPM," said Setters. "They ensure I can get the things I need on nights which most people never think about."

For the production employees, the biggest challenges are often faced by working late.

Training and clinic appointments often mean staying a couple of extra hours each morning, instead of heading home to sleep.

"My personnel and I sacrifice time with family, working the hours we work. But, we take great pride in knowing our hard work benefits the depot and, ultimately, the depot's various customers - most importantly, the war fighters of our military," said Setters.

Their pride in the work can take the shape of reporting issues which can be seen better at night.

Williams said the processes performed during night shift can often highlight safety issues or equipment problems.

"You see a lot of things at night that are not right, which may indicate safety or equipment issues, and you can bring those to the attention of the day shift supervisors," he said.

Social Sharing