NATICK, Mass. -- The U.S. Army Combat Capabilities Development Command Soldier Center (CCDC SC) is partnering with academia and industry to accelerate the development of wearable sensors for Soldiers conducting future Multi-Domain Operations (MDO).

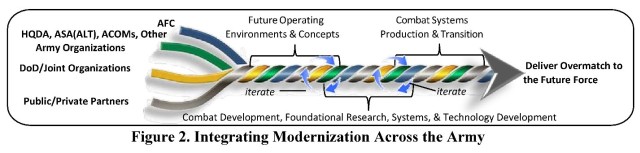

Representatives of CCDC Soldier Center led a collaborative innovation workshop with the U.S. Army Reserve 75th Innovation Command and in partnership with the University of Massachusetts, Lowell at UMass Lowell's Innovation Hub on 12-13 November to foster the collaborative behaviors needed to deliver the right technologies and capabilities to the future force. This approach aligns with the 2019 Army Modernization Strategy, particularly the integrated and iterative method (shown in Figure 2) to modernize across the Army and deliver overmatch capabilities.

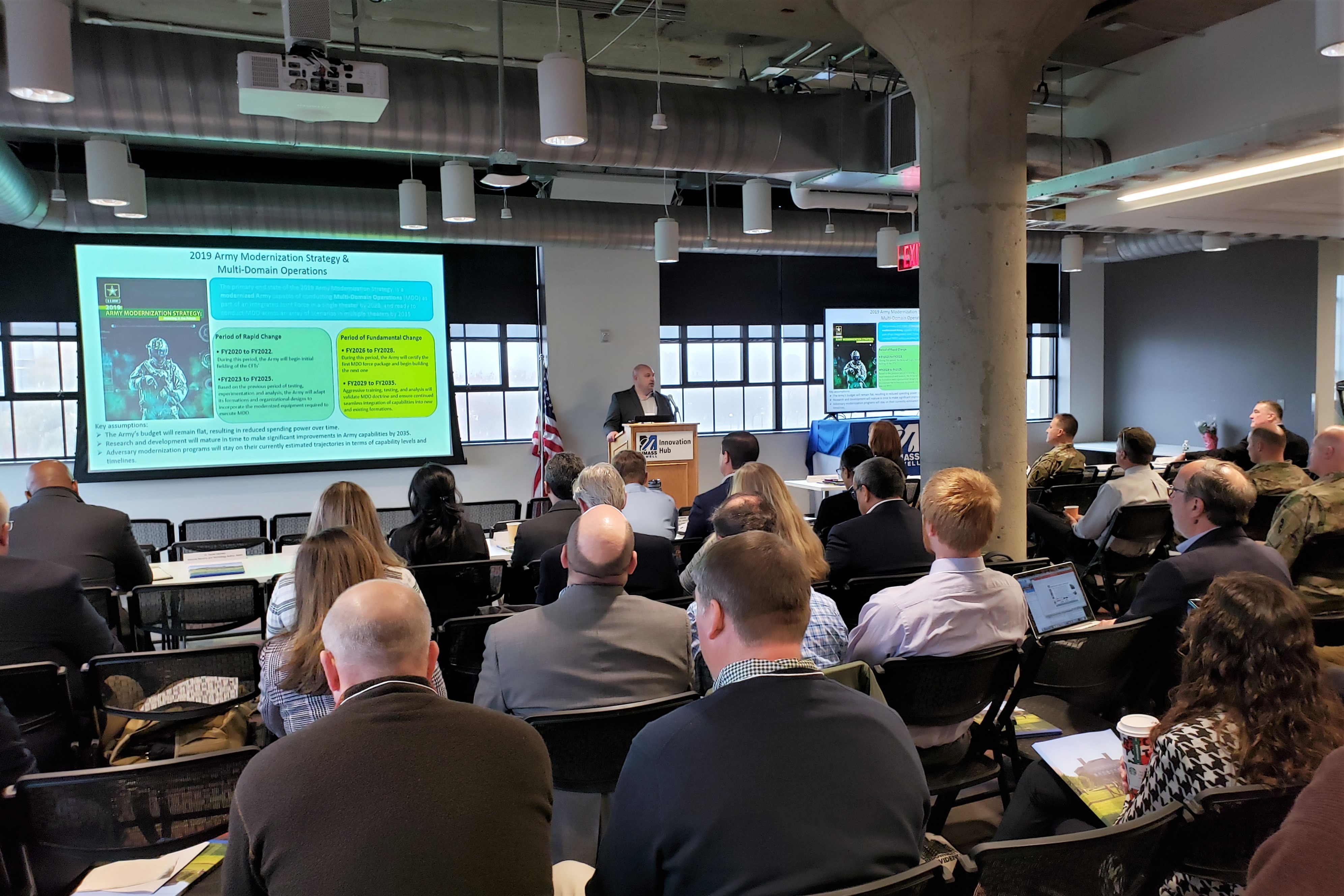

The event, titled "Wearable Sensors for Platoons Conducting Multi-Domain Urban Operations: Utility, Feasibility, Manufacturability," brought together experts from government, academia and industry to understand and address the technological capability gaps facing Soldiers during future combat on highly complex battlefields in urban and subterranean environments against near-peer adversaries in which wearable sensors will play a major role in enabling augmented reality to provide a decisive edge.

"The desired outcome is to sustain and enhance the Army's Future Force Modernization collaborative behaviors post event to ensure our warfighters continue to have the best technologies to achieve overmatch against our enemies," said CCDC Soldier Center's Military Deputy Col. Frank Moore during opening remarks.

More than 130 representatives across the Future Force Modernization Enterprise (FFME) attended the event, including: Army Futures Command (AFC); CCDC Army Research Lab; Maneuver Center of Excellence; Command, Control, Communications, Computers, Combat Systems, Intelligence, Surveillance, and Reconnaissance (C5ISR) Center; Army Medical Research and Development Command; Program Executive Office (PEO) Soldier; the U.S. Navy, the Department of Homeland Security; Asymmetrical Warfare Group; Massachusetts state government agencies; OSD sponsored National Manufacturing Initiatives; RAND Corporation; and approximately 20 individual companies working with the DoD which have product lines in the sensor field; as well as Drexel University; Massachusetts Institute of Technology; North Carolina State University; UMass Lowell; University of Penn; and Worcester Polytechnic Institute.

Presentations emphasized current and future Soldier operating environments and doctrinal impacts of executing in MDO environments, while others covered programs and initiatives relevant to wearable sensors and smart materials, Soldier performance, technology, and national manufacturing initiatives.

An illustrative video, which can be found at the web link below, was used to highlight operational challenges of MDO at the tactical level close area fight. The video showcases various capabilities required to achieve overmatch against threats and mission demands in an MDO environment.

Following the informational briefings, break-out groups were formed to focus on technology scouting and applications, and potential technical approaches to the use of wearable sensors during urban and subterranean missions.

The venue and format were key factors in creating the most collaborative environment for participants.

"Our Preferred Partner Program is all about working with our industry and government partners in a more strategic and holistic way," said Dr. Julie Chen, UMass Lowell's Vice Chancellor of Research and Economic Development. "We look to maximize R&D connections, workforce development (through co-op and graduate/professional education), access to technical equipment, and in general, the frequency of informal interactions."

"These interactions help address some of the key barriers that slow us down -- including simply understanding the same technical and government language, understanding what has and hasn't worked in the past, and designing from a systems perspective so we don't have amazing sensors with no practical way to embed, power or communicate," said Chen.

UMass Lowell's Innovation Hub at 110 Canal Street is the only facility in the country where three of the Manufacturing USA Institutes come together under one roof, according to Chen.

"Advances in wearable sensor technologies require the integration of many fields, including the Advanced Functional Fabrics of America (AFFOA), Flexible Hybrid Electronics (NextFlex), and Advanced Robotics for Manufacturing (ARM) expertise represented in UMass Lowell's Fabric Discovery Center." said Chen.

This makes it an ideal location to spur collaborative research and development of technologies that can measure, predict, and enhance Soldier performance -- central tenets of CCDC Soldier Center's Measuring and Advancing Soldier Tactical Readiness and Effectiveness, or MASTR-E, program.

Another example of how UMass Lowell stimulates innovation is their Medical Device Development Center, or M2D2, which offers biotech and medical-device startup companies coordinated access to the university's researchers and resources with the goal of bridging the gap between idea and market to find solutions to public-health emergencies.

The Army wants to apply the same collaborative approach towards executing its modernization priorities and has a designated unit working to expand the relationship between military and civilian innovation communities with the goal of finding and delivering solutions to national security threats.

The Army's 75th Innovation Command plays a critical role in generating the cross-sector partnerships and collective innovation needed to modernize its forces and increase its close combat capabilities.

"The 75th IC is broadening the solver community surrounding Army modernization," said COL Ron Corsetti, Officer-in-Charge of the 75th IC's 1st Group (Eastern Region).

According to Corsetti, the unit is composed of trained and experienced Soldiers who are also high-performing professionals in their private lives within areas important to modernization, which serves as a force multiplier to the Army's Future Force Modernization Enterprise.

"We have Soldiers that interact every day with the stakeholders of innovation ecosystems - government, academia, corporations, risk capital, and entrepreneurs in over 23 cities nationwide," explained Corsetti. "Our Soldiers serve to bridge Army interests in innovation ecosystems while bringing an understanding of those stakeholder's interests back to the Army.

"This is building better partnerships for the Army, improved national security, and a stronger U.S. economy," said Corsetti.

One concept discussed that could help the Army accelerate development of Soldier wearable technologies is implementing minimum viable product, or MVP, cycles. MVP can be defined as the earliest version of a product with sufficient functionality to allow developers to collect the maximum amount of validated learning about it with the least effort and cost put in.

"Industry has used minimum MVP cycles with great success," said Dr. Shawn Walsh, a research engineer in the Office of the Director at CCDC Army Research Laboratory. "An MVP cycle, in concert with well-designed experimentation, will allow the Army to test out new concepts and emerging science and technology much earlier, including candid and constructive feedback from the Warfighter concepts and requirements community."

"The private sector now greatly outspends the DoD on R&D innovation and the most disruptive technologies are coming from private sector innovation ecosystems," said Corsetti. "Harnessing the full potential of private sector innovation is vital if we are not to fall behind near peer competitors and ensure our national security."

The event demonstrated that solving the unique operational challenges Soldiers face while fighting in extremely dynamic, urban and subterranean environments requires the collective efforts of cross-sector partnerships and the Army's commitment to transforming how its Science and Technology (S&T) organizations get technology into the hands of warfighters.

Initial feedback from attendees and participants regarding the information, collaboration, facilities, and ability to work towards solutions was overwhelmingly positive.

"The participation by CCDC Soldier Center, the 75th IC, PEO Soldier, Army S&T groups, academia, and industry created a perfect environment for the exchange of information and networking," said Francisco Martinez, Chief Technology Officer of PTF Innovations. "All the speakers provided valuable insight about on-going and future programs."

"The MDO Wearables event, held at UMass Lowell's Innovation Hub, is an example of the Army 'leaning forward' into the future and catalyzing collaboration across government, university, and industry sectors," said Walsh. "It provides a vital path to move our science and technology off the lab bench and into the hands of future Warfighters."

"The MDO Platoon event co-sponsored by UMass Lowell and the 75th IC is a model for how the FFME can work to inform modernization decisions and bring the talent of a broad solver community to bear in advancing our Army," said Corsetti.

Many of the ideas and concepts generated during this event to support the Army Modernization Priorities and projects will enhance Soldier Lethality in MDO through effective increases in Soldier/Squad situational awareness, survivability and sustainment.

Collaboration teams formed at the event will continue to refine proposals for funding. The MVP approach will be utilized and select concepts are expected to be funded, resulting in additional Soldier touch points and prototypes in fiscal year 2020, which will be developed in partnership with National Manufacturing Initiatives AFFOA and NEXTFLEX. Additional innovation workshops focused on capabilities for MDO-capable close combat platoons are in the planning stages for calendar year 2020.

Social Sharing