CAMP WALKER, Republic of Korea -- The USAG Daegu Directorate of Emergency Services Health and Safety Office has commissioned new customized hearing protection equipment for their firefighters, taking into consideration the unique ear shape of each and every individual firefighter, and providing them with comfortable, top-quality gear.

Annual noise monitoring conducted by industrial hygienist, Dr. Pyongyol U, with U.S. Army Medical Department Activity -- Korea, suggests there exists excessive noise in Area IV's fire stations that could result in permanent damage to hearing over time, which is why hearing protection is a necessary safety measure. Conventional, disposable hearing protection equipment poses problems that can make wearing them an uncomfortable experience. Misfit in size and having to apply pressure to the ear canal walls for effective prevention of noise-induced hearing loss are distractions that can be eliminated with the right gear.

"Our rationale for providing firefighters with custom hearing protection is an internal initiative to proactively protect our most important asset, our firefighters," said Robert Edmiston, Directorate of Emergency Services chief of health and safety. "Custom-molded earplugs are much more comfortable for the end user and, once inserted, users of custom-molded earplugs are as physically aware of the earplug as they are of a watch or ring."

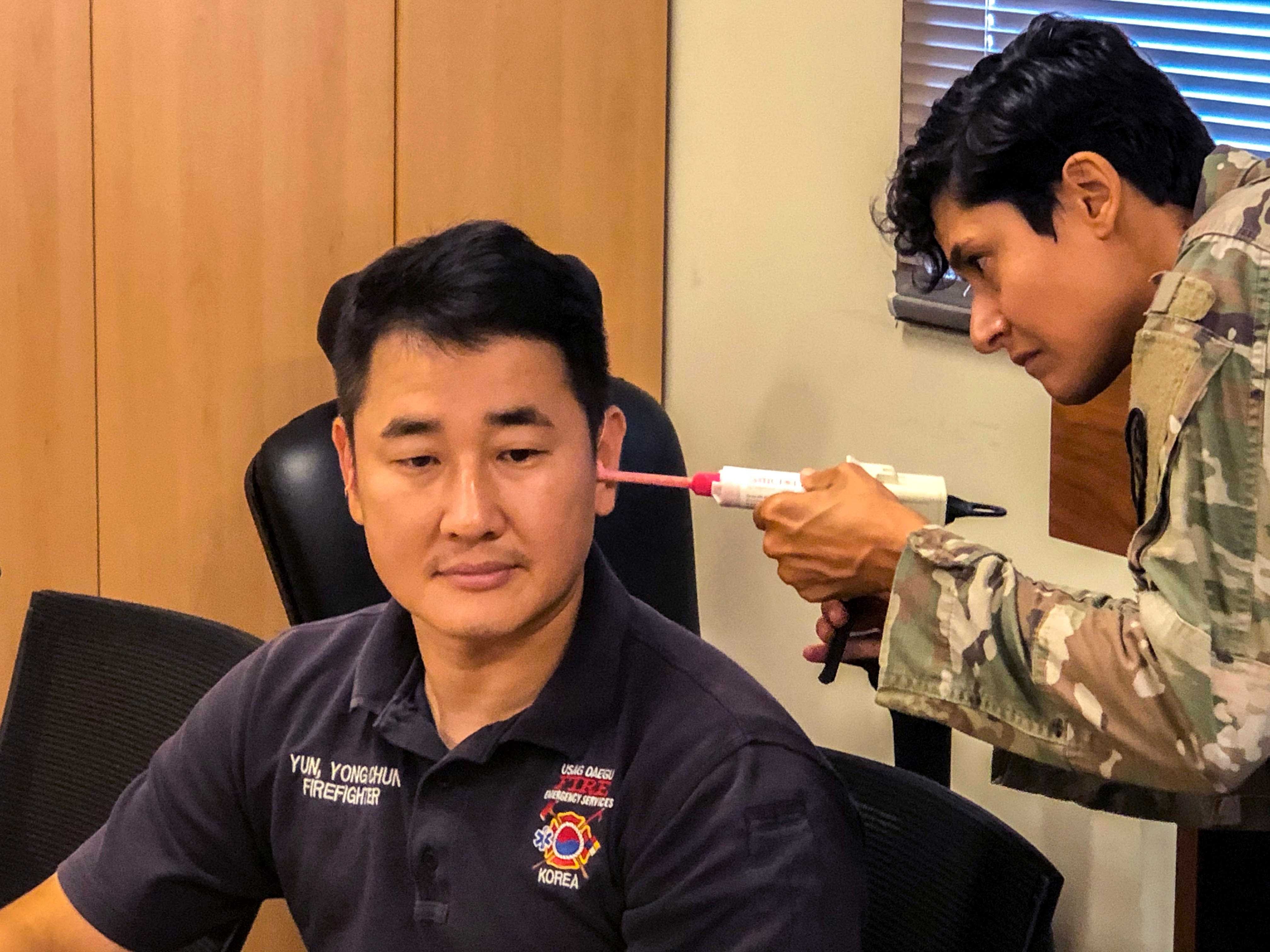

In the process of making customized earplugs, there was a need for professional inspection of each individual's ear in order to mold their respective impressions. U.S. Army Medical Command Doctor of Audiology Capt. Shauna Pearson from USAG Yongsan, assisted in making this procedure possible.

"Captain Pearson spent an entire week here in Area IV, visiting all of our fire stations and making ear impressions of all 75 fire department personnel," said Edmiston.

After all impressions were made, they were packaged and sent to the vendor in the U.S. to manufacture the customized ear-plugs. The vendor will also be digitally scanning and storing every ear impression in their system electronically. This process will make it possible to use the digital copies of the impressions to remake the customized plugs without going through the whole process of inspecting and making impressions again.

"When hearing protection is fit for the individual it's a lot more comfortable and I feel like there is more buy in for that individual because they participated in the process," said Pearson. "I haven't had any units take this initiative before, and it was great to work with Bob Edmiston and see how much he cares about the health and safety of his firefighters."

Social Sharing