REDSTONE ARSENAL, Ala. - The Army Primary Standards Laboratory (APSL), home of the most precise calibration standards in the Army, is receiving a long-awaited, multi-million dollar renovation which will lead to a better work environment, more calibration area and, most importantly, improved Army readiness.

"Once the entire renovation is complete, we will have a first-class facility to match the first-class calibration professionals supporting Army readiness worldwide," said Dr. Myra Gray, the U.S. Army Test, Measurement and Diagnostic Equipment Activity (USATA) Executive Director. "The improvements to both calibration areas and the reconfigured support space are long overdue and will enhance our ability to increase productivity and decrease the turn-around time for much of the equipment we certify."

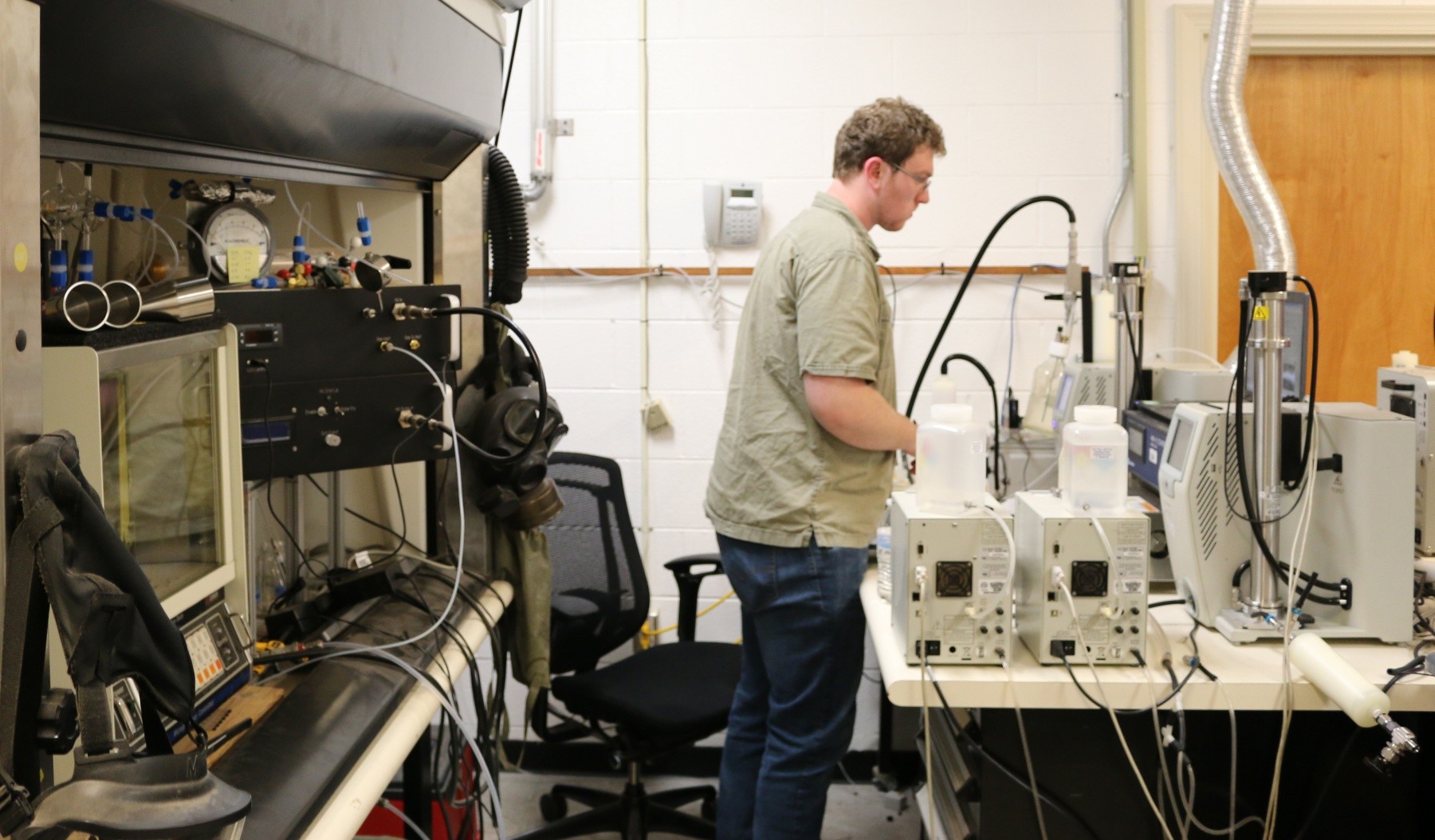

The APSL calibration and measurement standards, as well as the laboratory's environmental conditions, are essential to maintaining USATA's accreditation and their accuracies, which are traceable to the National Institute of Standards and Technology's (NIST) national reference laboratories. USATA metrologists, the formal name for calibration technicians who certify the accuracy of measurement devices, support every Soldier and every weapon system used by the Army. Without accurate, calibrated measuring devices, the readiness of the Army's aircraft, rockets and missiles would be degraded, which in turn would degrade the Warfighter's capabilities.

The APSL on Redstone Arsenal, Alabama, dates back to 1963, and several additions and modifications to the original laboratory have occurred since the original construction. The last major expansion occurred in the 1980s. The chain of accuracy for the Army starts with the APSL's calibration spaces. According to Martin Roggio, USATA director of management and operations, the outdated facility lacked the environmental and physical structures required to perform today's mission effectively and efficiently.

"The current space is being reconfigured to provide more and improved calibration areas," said Roggio. "More importantly, we are upgrading all of the environmental systems and replacing the degraded shielding in those calibration areas that are sensitive to electro-magnetic interference."

The process of calibrating very precise TMDE requires tightly controlled temperature and humidity levels throughout the laboratory. Temperatures in some of the areas physical/dimensional "clean rooms" must be maintained at 68 degrees Fahrenheit plus or minus .1 degrees and have very tight airborne contaminate (dust) tolerances.

"We had a tough time maintaining the environment within the tight tolerances required for the standards we maintain," said Roggio. "Additionally, in the first phase, we have added a clean room to the Chemical/Biological laboratory. This along with the larger work area is really going to reduce calibration time for these types of detectors."

The entire $32 million, 30-month renovation project consists of six phases and will create an additional 10,000 to 12,000 square feet of calibration space. With the completion of the first phase later this month, calibration equipment and technicians will move into the first completely renovated calibration spaces very soon, according to Chase Hollingsworth, a U.S. Army Corps of Engineers project manager from the Mobile District.

"The first, most extensive renovation phase for the APSL was scheduled for 12 months," said Roggio. "With the completion of this phase, we will be almost halfway through the project."

The renovation of APSL includes much more than improving the physical spaces functionality. According to Hollingsworth, there were many areas not normally seen that needed to be addressed.

"Several areas have materials containing asbestos including duct work and flooring that must be remediated," said Hollingsworth. "Contaminated soil must also be removed and disposed of while excavating for new utility service. Additionally, all utilities and communication systems throughout the building will be updated as part of the contract."

Once the equipment and people move into the completed phase 1a space, expected by the end of October, phase 1b can start. The entire project required extensive planning to ensure USATA's mission would not suffer because of the renovation to their primary laboratory.

"We spent almost two years planning for this major renovation project," said Wade Weaver, USATA facility manager. "It was very important that the existing calibration areas remain usable during this phased construction project."

The entire process started with a smaller renovation of an adjacent building (Bldg. 5436) which created new office space for much of the USATA support element, according to Weaver.

"We would not have been able to complete this renovation and keep the calibration areas functional without freeing-up much needed flex space in the APSL," said Weaver. "Creating new calibration work areas in spaces that were previously used as office space will allow us to move our calibration technician into their new work areas and start the next phase of the renovation."

With the first phase of the renovation nearing completion, the entire project continues to be on schedule, said Hollingsworth.

"Keeping [APSL] operational during the process has been a challenge but the contractor has met the user's needs," said Hollingsworth. "They are on-track to complete the entire renovation project by March 2021."

The complete renovation of such a large and complex calibration facility requires teamwork and a dedicated workforce willing to adapt to the challenges of working in and around an active construction zone. According to Gray, her team continues to meet that challenge.

"The USATA team at the Army Primary Standards Laboratory continues to provide calibration and measurement services in support of Army readiness, executing our efforts in the midst of this renovation project," said Gray. "Our folks all have the same end-state desire - to have a world-class calibration facility where they can continue to enable Army readiness through accuracy."

Social Sharing