After trials, SPITFIRE'S first customer test began Aug. 1 and will continue into September, as various swatches from seven different commercial, off-the-shelf containment bags are tested for the U.S. Navy (Dugway frequently tests chem/bio defenses for all services). Each sample swatch must safely contain a liquid chemical agent for 14 days.

Tested bags range from a letter-sized evidence bag to an adult-sized bag for human remains. The Navy seeks a range of bags for its Explosive Ordnance Disposal personnel, to transport contaminated samples from the battlefield.

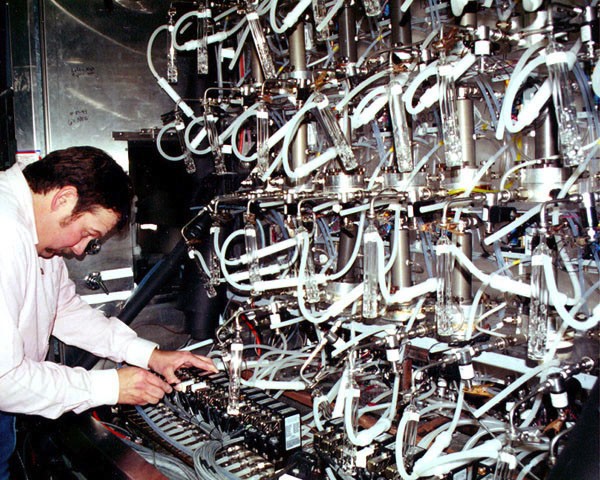

Both SPITFIRE and its predecessor AVLAG (Aerosol Vapor Liquid Assessment Group) are challenging swatches for the Navy test. Though AVLAG is more laborious to work with, it's still operable.

"We do a lot of swatch testing, so having multiple swatch fixture is advantageous to us," said Aaron Rogers, project scientist.

But overall, SPITFIRE has more advantages than AVLAG and may someday replace it. SPITFIRE is designed to be used in a wheeled glovebox with attached airlock, making it portable and easier for an agent handler to use. AVLAG is immovable, used in a wall-mounted hood, and requires more dexterity.

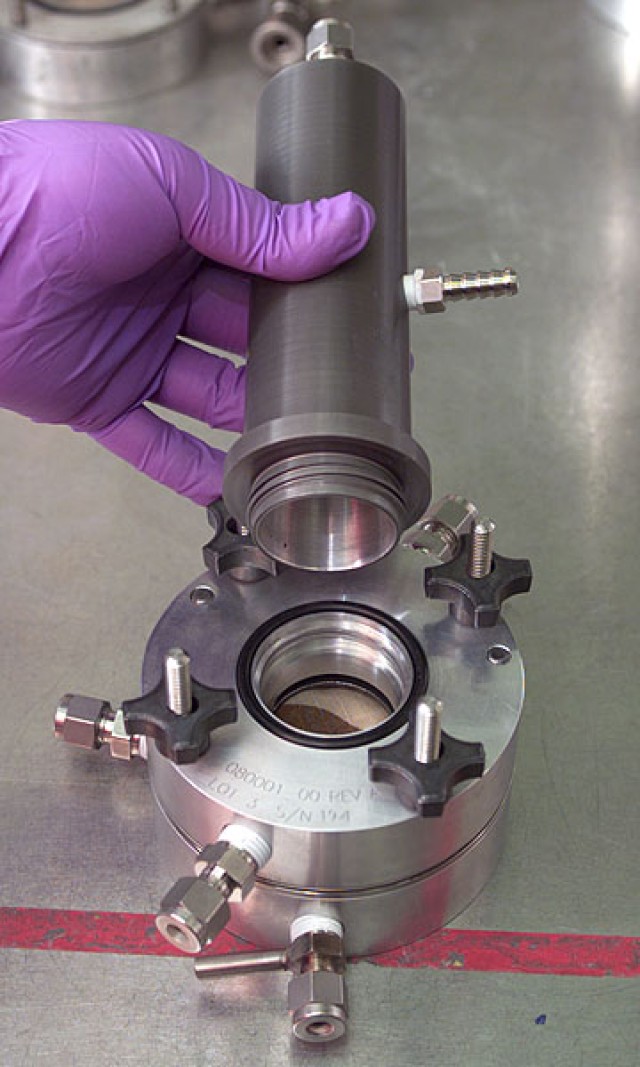

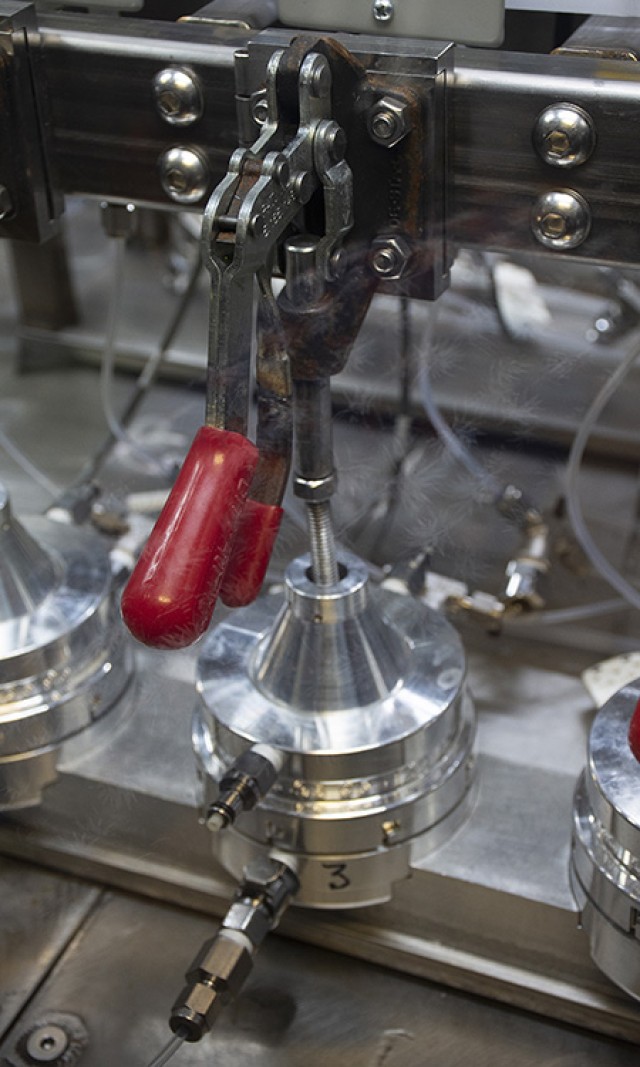

SPITFIRE's components are held together with the tension of a clamp; AVLAG uses multiple bolts and components. Each AVLAG unit is designed for a certain swatch thickness, while SPITFIRE can accommodate a variety of material thicknesses, ensuring a tight seal that prevents swatches from getting wrinkled or creased.

"It means more reliable data, because of tighter cup-to-cup variability than AVLAG," said Rogers.

SPITFIRE has very precise control over humidity, and its temperature control is more accurate than AVLAG. SPITFIRE is easier for the agent handler to use, a metal cup that holds the swatch may be switched out while the other cups continue testing. With AVLAG, testing with all cups must be temporarily halted during a single change-out.

The list of SPITFIRE advantages over AVLAG goes on.

"The main thing was to design this for ease of operation, safety in operation and much higher quality data," Rogers said. "For our agent handlers, it's much safer."

For the ultimate customer -- The Warfighter -- swatch testing means the Warfighter can trust his protective clothing to defend against chemical agent as expected.

"It enables the Warfighter to make better decisions on the battlefield and to ensure the Armed Forces have the best quality materials for the Warfighters," Rogers said.

-30-

Social Sharing