The Technologies and Investments Directorate (TID) is tasked with looking into the future and anticipating Yuma Proving Ground's (YPG) and Yuma, Cold Regions and Tropic Region's Test Center's, needs. Todd Hudson, Director of TID explains, "We are responsible for sustainment, enhancement, and modernization of YPG's test capabilities and integrating new technology and innovation to ensure YPG has the test capabilities to meet Army and DoD modernization and mission objectives."

The directorate has several functions, which include leading YPG's investment process, enterprise software development, fostering new technologies, providing support to the Army Futures Command, sponsoring or developing test policies and standards such as Test Operating Procedures and testing research which includes partnering with various government entities, academia, and others to advance innovations in the testing arena.

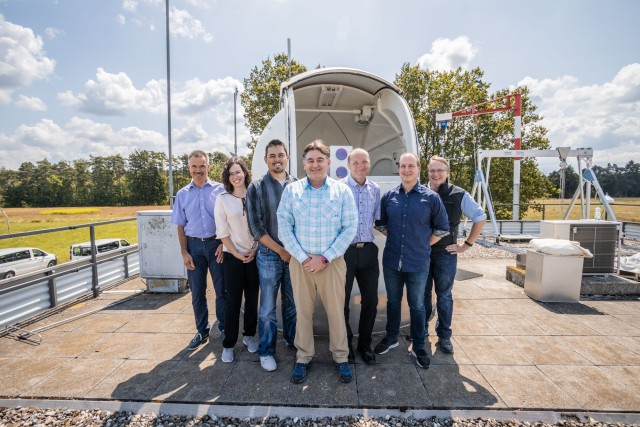

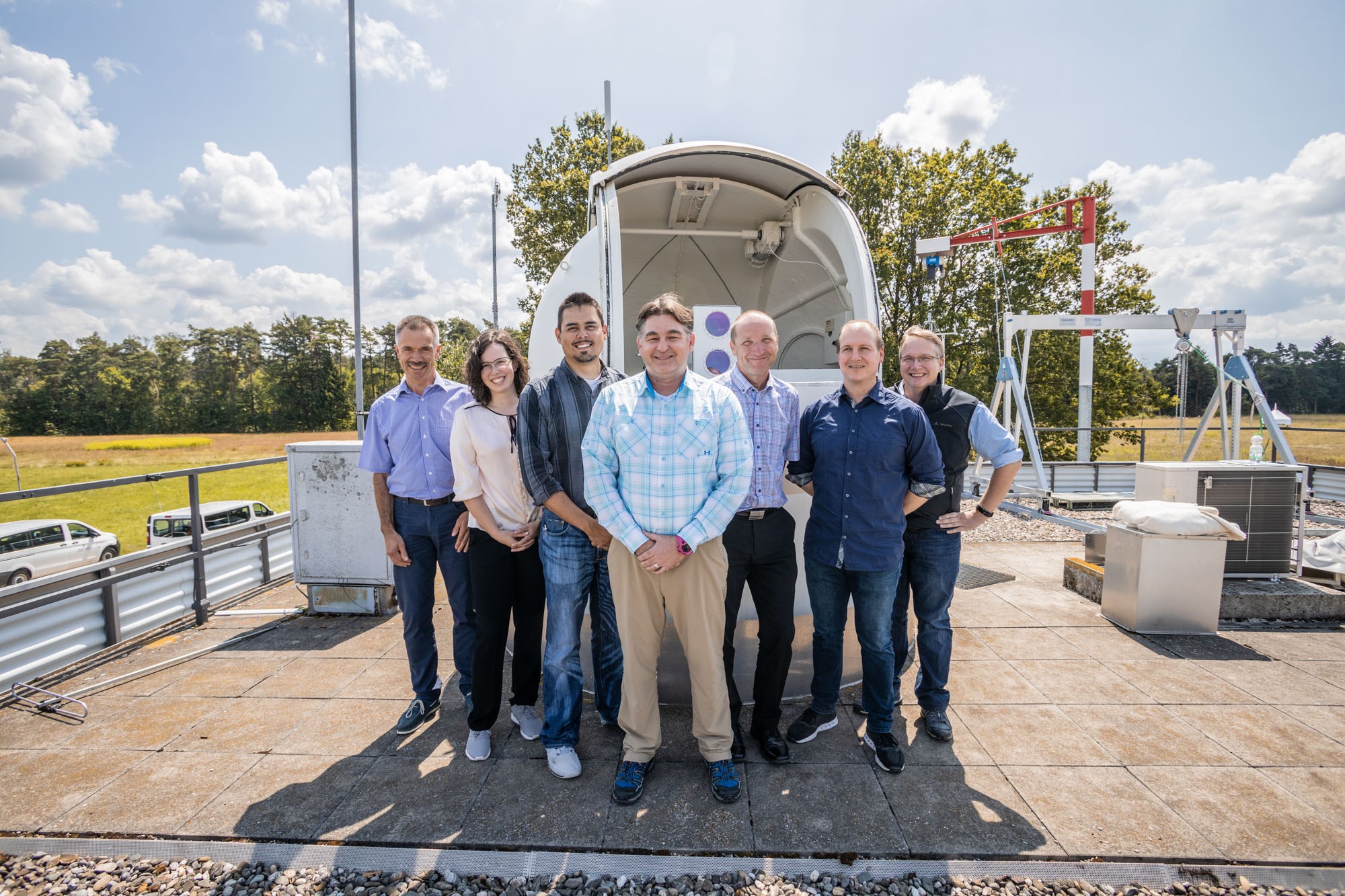

Recently, Hudson and George Franck, the Technology and Investments Manager, focused on the latter two of those functions when they visited Germany's Technical Center for Weapons and Ammunition (equivalent to a test center) and hosted their German counterparts at Yuma Test Center (YTC) earlier this summer. The technical centers test equipment for their government similar to what YPG does for our government.

Hudson explains that Germany is using very similar non-destructive test equipment that is used at YTC's Metrology and Simulation Division for cannon tube inspections. The trip was focused on cannon inspections since the Germany technical center uses similar techniques as YTC for indirect fire cannons. The hope is to collaborate and learn from one another, "The Germans have recently acquired the technology within the past two to three years. So they are new to it and are trying to understand it. Us being able to help them is going to save them a lot of time" explains Franck.

Hudson adds, "We can share ideas, collaborate on research methods and technologies and develop policy changes and standard updates." One of the action items resulting from this trip is a working group to update the International Test Operating Procedures (ITOP).

"We are establishing a working group between our two countries to update this ITOP to include laser bore mapping techniques for cannon inspections."

Anyone within the international NATO allies would use the ITOP to ensure all inspection techniques and requirements meet the same standards. During their trip to Germany Hudson and Franck noticed there is work to be done when it comes to standardizing the inspection process.

"A lot of their inspection criteria is different than ours so as we want to come up with standardization policies and procedures for laser bore mapping there's gaps we are going to have to agree on how we identify flaws and different characteristics with the cannon tubes" explains Franck.

While this trip was focused on laser bore mapping TID is always looking to link its subject matter experts (SME) says Hudson, "As we meet experts across the world, we look for opportunities for collaboration. We foster this exchange and get our SMEs linked up with their SMEs."

Hudson points out that there are many benefits to sharing research methods and technologies and policy changes and standard updates. "Overall, collaboration with our national and international partners, that's what we are supposed to do. We are supposed to see what they are doing in Test and Evaluation and they see what we are doing. Together, in a collaborative nature we can become better Test and Evaluation professionals for both our governments."

Adding that the possibility of a collaboration like this leading to the next innovative design are not farfetched. "So when we do the next version of laser bore mapping, now it will be a collaborative between YPG and Germany to go back to the manufacturer and build something even better than we have now."

Social Sharing