WATERVLIET ARSENAL, N.Y. -- Watervliet Arsenal will install new machines in the historic 'Big Gun Shop' to increase cannon production capacity.

The demand in increased capacity results from the Army's prioritization of long-range precision artillery to meet potential near-peer threats.

"Long-range artillery has been in the arsenal's wheel house since 1883," said Joseph Turcotte, Watervliet Arsenal deputy to the commander. "The Army's prioritization on long-range artillery is the push behind expanding our manufacturing capacity and driving our modernization efforts. It is imperative that we have the tools necessary to fulfill our mission to the Department of Defense and this is an important step in completing that goal."

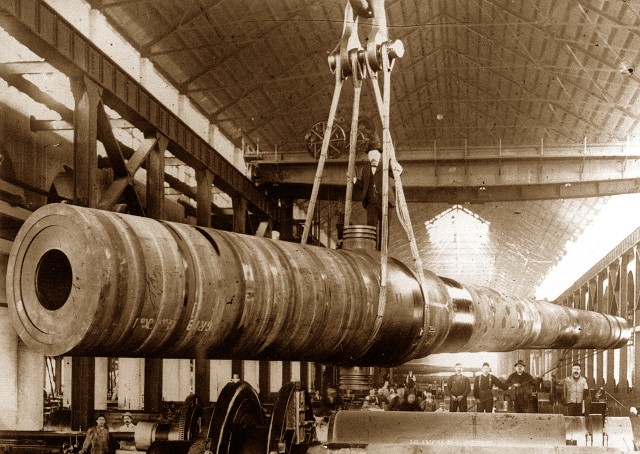

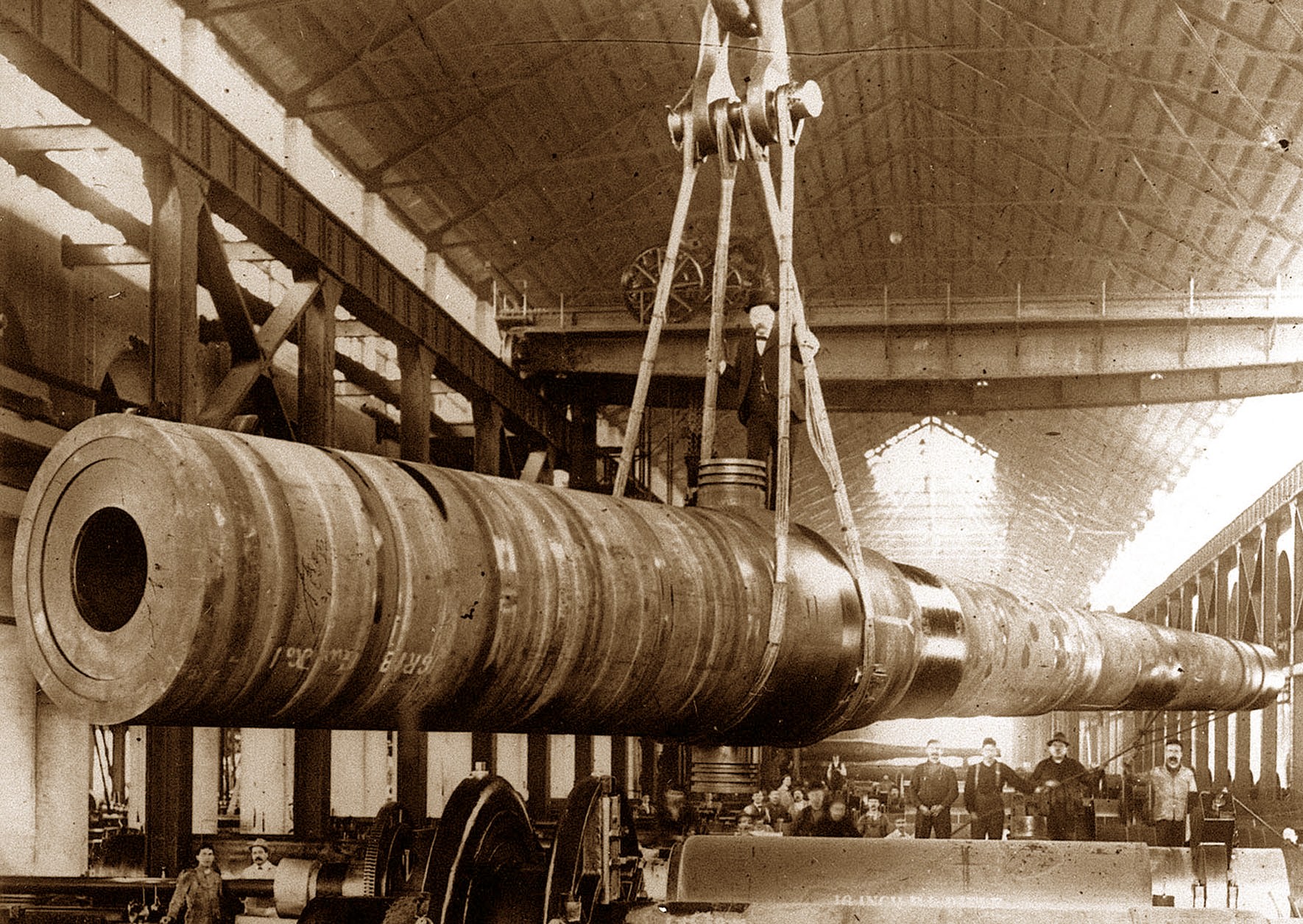

Built in 1889, the quarter-mile-long 'Big Gun Shop' is the arsenal's oldest manufacturing facility. The building earned its name by being home to 16-inch seacoast and battleship gun production. The arsenal's big guns were used in every conflict from the Spanish American War through the Persian Gulf War. Major cannon work ceased during the drawdowns of the 1990s resulting in machines being removed and cannon work shifting to other buildings. Since then, the building has been primarily used for minor work including paint, preservation and composites. A large portion of the facility was left unutilized.

In response to increased workload demands, the arsenal is increasing production capacity making the 'Big Gun Shop' the perfect location to house new equipment on the 143-acre installation. The machines will perform a variety of manufacturing functions including turning operations, straightening and abrasive blasting.

"New requirements and more machines to produce at increased rates are what is driving this latest batch of equipment," said Tim Fontaine, industrial engineering specialist with the arsenal's capital improvement program.

In addition to increasing capacity, new machines being installed will future-proof the arsenal's capabilities by ensuring the arsenal can meet tomorrow's production requirements.

"Being able to produce future weapon systems is a primary focus when planning new machines," said James Kardas, industrial engineer with the arsenal's capital improvement program.

The 'Big Gun Shop' revitalization is the latest in a series of recent capital investment projects at the arsenal. Which, according to Watervliet Arsenal Commander Col. Milton G. Kelly, reflects the Army's commitment to the historic arsenal.

"Investment in new machines is a testament of the Army's faith and trust in the arsenal to perform its mission and do it well," said Kelly. "These new machines help us become more efficient and respond to future requirements."

Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest continuously active arsenal in the United States, having begun operations during the War of 1812. It celebrated its 200th anniversary on July 14, 2013. Today's arsenal is relied upon by the U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannons, howitzers and mortar systems.

Social Sharing