One of the advancing capabilities in sustainment operations is that of automatic identification technology (AIT), which can increase the accuracy of inventory records by automating the required data collection and enabling transmission of the data to and from military systems.

The Army has implemented the use of AIT as its inventory control technology of choice. But the equipment sits unused in forward theaters because of outdated policies, network constraints and a lack of training.

The AIT suite encompasses a variety of data storage and carrier technologies such as one-dimensional linear bar codes and two-dimensional (2D) symbols. The AIT suite can be combined with other technologies, such as active radio frequency identification (RFID), and can be used to read the stored data of equipment such as military vehicles and materiel in intermodal containers. Together, those systems can provide the in-transit visibility that the military requires; commanders will have the critical information they need to track unit cargo and sustainment materiel through the supply chain, from production to forward storage areas.

An example of how AIT works in our everyday life: Order a package at Amazon.com, and Amazon will track it from the distribution center to you. The bar code on the package enables this, and can provide virtually instant confirmation of delivery. Similar labeling and scanners within Amazon's facilities enable inventory management. This technology benefits asset management by informing Amazon.com that the item has reached its destination and allowing the company to see how many are still available to order.

The military sustainment community uses this technology extensively, providing sustainers the ability to properly inform commanders of assets in transit. The U.S. military has the world's largest active radio frequency in-transit visibility network, spanning 41 countries with 1,749 RFID tag read-and-write sites and more than 570 satellite-enabled tracking systems. Passive RFID, an electronic identification technology comprising a chip and antenna imbedded within a label, is also used in the defense supply chain but is not designed to carry large amounts of data and is not currently approved for use on ammunition and missiles.

In the continental United States, AIT suites support the receipt of sustainment supplies and equipment in the Army's organic industrial base, comprising 23 manufacturing arsenals, maintenance depots and ammunition plants. The AIT suite can be used to track the inventory in short- or long-term storage awaiting issue to units. U.S. Transportation Command, which leads the joint deployment and distribution enterprise and is the proponent for AIT and in-transit visibility, has been looking for additional ways to take strategic advantage of AIT to support commanders who have to make logistics decisions in tactical and operational missions.

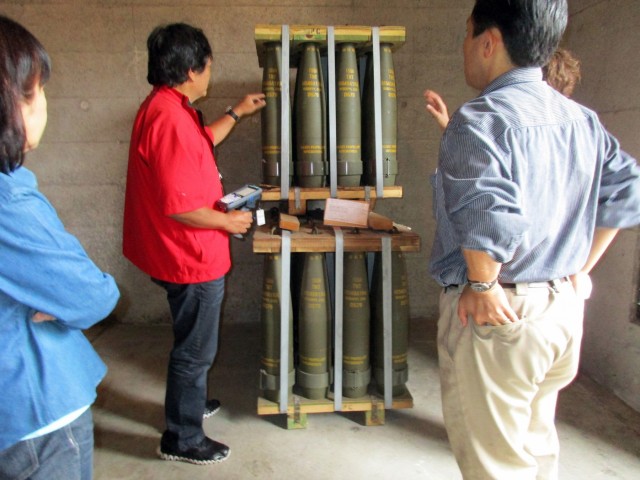

One of the most important functions of AIT at theater ammunition supply points is the ability to process serial numbers, using handheld terminal bar code readers, on items such as guided missiles and large rockets during receipt and inventory of ammunition material. The use of AIT can reduce a full day of checking serial numbers to a matter of a few minutes, freeing personnel to perform other critical tasks.

IMPLEMENTATION OF AIT

The Joint Ordnance Commanders Group, a flag and general officer forum in which all the services' conventional ammunition stakeholders jointly define and improve munitions management systems and execution, has an AIT subgroup that in 2011 implemented joint ammunition package label specification. The objective was to streamline bar code processing and effectively use AIT to enhance tracking systems and standardize labeling and tasks.

The Army has created a policy to procure AIT suites and have them available at theater ammunition storage activities through the system managed by the Product Lead for Logistics Information Systems under the Program Executive Office for Enterprise Information Systems. However, the Army faces many challenges in adopting new technology of value to ammunition management, such as network constraints and a lack of training on the use of AIT.

The ability to use AIT and integrate it with military ammunition systems is the key to AIT's rapid acceptance. Its primary use is to facilitate data management in the areas of cost, processing time and data accuracy. AIT can replicate bar code data, reducing the risk of keystroke errors that can create shortages and take time for inventory personnel to correct. Additionally, AIT can help monitor how responsive the supply chain is to commanders' requirements for battlefield munitions.

AIT UNDERUSED IN THE FIELD

The Army uses the Standard Army Ammunition System (SAAS) as its web-based ammunition system to provide accurate, real-time stock status in a theater of operations. The ammunition system is used at the point of issue and management levels. The real-time transfer of data makes the management of munitions more precise and satisfies the commander's requirements for tactical information on conventional ammunition. While the system offers the ability to track munitions on hand, it relies on personnel to manually receive and inventory ammunition, a time-

consuming process. At the same time, the units have AIT on hand but are not able to use it.

The total cost of the AIT suite is approximately $19,000 for a system at an ammunition supply point and $8,000 for a system at a unit ammunition transfer and holding point. Generally speaking, these prices are on the low end compared with the newer technology currently available through the indefinite-delivery, indefinite-quantity contracts for AIT. The equipment is authorized to 55 support battalions and 18 ordnance sections. Despite a sizable investment of about $782,000 in handheld terminals and portable printers for forward ammunition support activities, Soldiers in the field are not able to use the AIT equipment to conduct inventories or receipts. It remains underused, or not used at all.

CHALLENGES TO OVERCOME

One of the challenges in adopting AIT is developing institutional knowledge. While the military occupational specialties 89A (ammunition stock control and accounting specialist) and 890A (ammunition warrant officer) are responsible for SAAS, AIT is not part of their professional military education. At the unit level where the AIT resides, Soldiers thus find themselves with equipment they cannot operate.

An operational challenge is that the USB cradles for handheld terminals must be plugged into a computer on the Non-Secure Internet Protocol Router network, requiring an exemption from the network enterprise center for USB activation. Without the cradle, the data cannot transfer from the handheld devices to the website application. Additionally, information technology personnel do not have the experience to integrate handheld terminals with the SAAS and cannot configure AIT equipment for use at units. To process AIT and RFID, the handheld terminals must be preloaded from the product lead's offices.

In 2017, the transition from the server-workstation ammunition system to the new web-based system changed the interface between the system and AIT. Since that transition, the product lead has been overwhelmed with trouble tickets to fix errors discovered after implementation. The initial vetting of the website did not account for the many problems that each ammunition supply point faces. In the Japan theater of operations alone, stock control clerks submitted 26 tickets in the first five months of migrating the database to the servers at Fort Lee, Virginia. Keeping up with the baseline website has been the priority of the product lead, and anything AIT-related has been a low priority, as manual procedures may be used in its place.

While the team at the product lead office created a great website that replicates the setup of servers and workstations in the ammunition system, the AIT suite still sits idle at locations that cannot implement hardware involving the local network enterprise center and integrated with the newest version of the software. One of the major difficulties is the inability to fix the transfer of data from the handheld terminal to the ammunition system. The product lead team has waited for the next software version to correct serial number errors in inventory transactions.

The inability to use AIT at theater ammunition supply points also stems from current policy and procedures. The use of AIT should be part of the automated receipt and inventory processes, and the definition of administrative adjustments should include errors with AIT. This would give commanders and officers responsible for supplies waiting to be issued flexibility in using AIT for accountability functions. Current Army inventory processes still mandate the use of a counter and recorder with DA Form 2000-3, Installation Inventory Count Card, for manual procedures, or the SAAS-generated inventory count sheet for automated procedures. The reason for not integrating AIT into automated procedures is that much of the current Army ammunition management regulation mirrors what was written in 1998 for supply support activities.

EFFECTIVENESS OF AIT FOR AMMUNITION

Theater ammunition aside, the organization with the most experience in managing ammunition is the Army's organic industrial base under Joint Munitions Command, which manages all of the ammunition plants and depots in the continental United States. These facilities use a different ammunition system. Implemented in 2015, the Logistics Modernization Program (LMP) allows national-level ammunition management to integrate multiple systems for receiving, storing, surveying and issuing ammunition.

With the latest version of LMP, data goes directly from standardized AIT handheld terminals into the national ammunition system, improving the accuracy and timeliness of data as well as reporting for strategic management. The acquisition functional lead for LMP reported that organic ammunition depots have fully functioning "store and forward" AIT, which allows employees to send information to intermediate stations where it is stored and sent later to the national ammunition system.

An ammunition plant as large as McAlester Army Ammunition Plant in Oklahoma, for example, requires the use of AIT. The ammunition plant, one of the largest, sits on 44,964 acres with 2,826 buildings, including 2,263 earth-covered storage magazines, 173 storage warehouses and a storage capacity of 8.8 million square feet.

CONCLUSION

Ultimately, the benefit of advanced technology depends on the training and skills of the people who employ the technology. AIT works only as well as the capability of the ammunition system, supply policy and processes, and the training provided. These factors cannot be taken separately; until they are combined for an effective result, at best only a fraction of the optimal in-transit visibility solution will be available.

The problem requires the Product Lead for Logistics Information Systems to develop and implement effective AIT in the field for Soldiers and civilians who use the ammunition systems. The product lead must make integration of AIT into SAAS a priority and take corrective action on the backlog of errors with AIT. Additionally, end users need a stand-alone guide on how to use the software and send data from AIT to computers with the new version of SAAS, and IT personnel need training support packages to help them set up the software on computer systems for AIT.

With proper initiative and training at all levels, Army employees and Soldiers can conduct receipt and inventory of ammunition supplies with AIT, improving cost, processing time, accuracy and performance monitoring of data while informing commanders of stock availability and developing the commander's requirements needed to win our nation's wars. A combination of updated doctrine and user manuals, along with training support packages, can give the ammunition community the push it needs to change how it completes ammunition operations and processes.

AVAILABLE TECHNOLOGY

Army policy directs that all commanders with AIT fully integrate the accountability functions of receipt, storage, inventory, issuance and shipment of sustainment materiel. The AIT suite can be used to scan bar codes. The DOD supply chain uses three types of symbols: linear bar codes, 2D PDF417, and the 2D data matrix. Bar codes carry a maximum of 15 to 20 characters. The 2D symbols are more complex: PDF417 symbols contain address and package identification. Data matrix symbols are used for mandatory unique-item identification.

Active RFID tags contain the same information as packaging labels, and are used in tagging a variety of assets in transit and to provide location information when shipments of containers pass RFID interrogators at network nodes. One of the leaders in the supply chain industry that uses AIT and RFID technology is Walmart Inc. Walmart has been using universal product codes (found on linear bar codes) since 1983 to collect information for analysis to support strategic distribution and supply plans. The company's supply chain uses RFID to track pallets of merchandise, and employees use handheld scanners to read smart tags and identify which items need to be restocked. The military has leveraged these same technologies.

For more information, go to https://usarmyamis.army.mil/Contracts_AITV.html.

CHIEF WARRANT OFFICER 3 MICHAEL K. LIMA is the ammunition warrant officer with the 10th Support Group, Torii Station, U.S. Army Japan. He has served in the Army for 20 years. He is a graduate of the Warrant Officers Advanced and Basic Courses. He holds a DBA in business and an MBA in human resources from the Baker College Center for Graduate Studies, and a B.S. in aviation management from Farmingdale State University of New York. He has been awarded the Meritorious Service Medal and is a designated Demonstrated Master Logistician.

This article is published in the 2019 Summer issue of Army AL&T magazine.

Social Sharing