NATICK, Mass. -- It turns out you can make a career out of saving money and equipment, all while keeping the warfighter safe.

Jim Varnum has done just that.

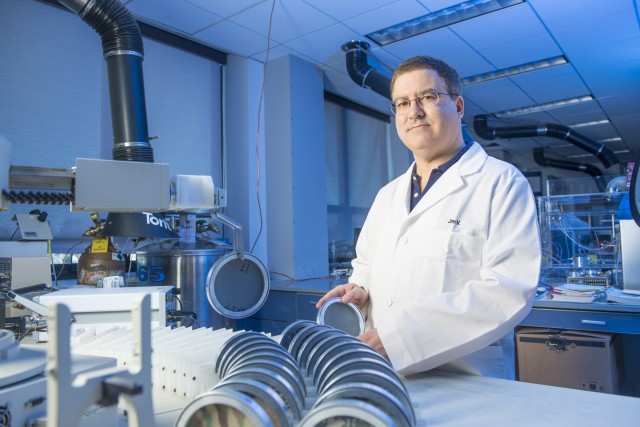

Varnum, a chemical engineer, manages the Chemical Protection Stock Surveillance Program in the Soldier Protection and Survivability Directorate at the Combat Capabilities Development Command Soldier Center, or CCDC SC.

CCDC SC, formerly the Natick Soldier Research, Development and Engineering Center, began working on stockpile surveillance in the 1980s. Over the years, Natick's work has saved millions of dollars in equipment assets, preventing the unnecessary shelving of garments that are still effective -- all while ensuring that the garments still provide protection -- thus ensuring warfighter safety.

CCDC SC is dedicated to using science and technology to ensure America's warfighters are optimized, protected, and lethal. Although CCDC SC supports all of the Army's Modernization efforts, the Soldier Lethality and Synthetic Training Environment Cross Functional Teams are the CCDC SC's chief areas of focus. The center's science and engineering expertise are combined with collaborations with industry, DOD, and academia to advance Soldier and squad performance.

Varnum has been hard at work since 1995 overseeing the Chemical Protection Stock Surveillance Program and shelf-life testing. The effort tests the shelf life of chemical protective clothing to determine how often re-testing is needed and at what age the garments become ineffective.

"I've been doing the stockpile surveillance work since 1995," said Varnum. "When they build a chemical protective suit they need to give it a shelf life based on the materials used. Usually, they are fairly conservative in their assessments because you don't want to have a suit out there that is no longer effective in protecting the warfighter."

Varnum's work helps potentially extend shelf life.

"A shelf life for a garment might be, for example, five to ten years," said Varnum. "When it gets to be near the end of the shelf life for a given item, thousands of over-garment items will be scrapped unless someone can show that they are still effective. So, we here at Natick proposed to develop a test plan for these assets and find out if they still perform as well as they did when they were new. And if the test shows that they do, the shelf life can be extended, ensuring safety but also saving money and assets."

For example, the Battledress Overgarment, or BDO, had originally been given a five-year shelf. Long-term test data gathered by Natick demonstrated that after 10 years many of the garments were still effective. After 15 years, however, a very small but significant portion showed signs of degradation. Thus, the BDO could no longer be used after 14 years.

CCDC SC continues to carry out testing on another protective garment called the Chemical Protective Undergarment, or CPU. CCDC SC currently conducts physical and chemical tests on CPUs for JEFS -- the Joint Program Executive Office for Chemical, Biological, Radiological and Nuclear Defense (JPEO-CBRND) Enterprise Fielding and Surveillance Directorate. JEFS, formerly known as the Joint Equipment Assessment Program, has presided over the surveillance of chemical-biological protective items since 2006 and determines which sets of items need to be tested -- and then sends the items to CCDC SC, where the actual testing is carried out.

The garments undergo two types of testing. A chemical test determines if the garment is still providing chemical protection. Physical properties testing, which includes testing the potential for tearing, examines if the garment is going to hold up with use.

In addition to carrying out testing, CCDC SC also developed an automated test in the 1990s, which saves both time and money by using a chemical simulant rather than an actual chemical-warfare agent. The once labor-intensive test was automated and renamed the Automated Robot Vapor Adsorption Test, or ARVAT. Currently, the CCDC SC is the only lab conducting this test.

"The chemical test is a chemical simulant test using a nontoxic simulant that mimics chemical warfare materials," said Varnum. "Because we are doing this by simulant it is not only much safer than using an actual chemical agent, it is also cheaper. A simulant test is a better way to go than an agent test for these garments. So the thinking is to use an agent in the first testing and also do a simulant test at that time and then retest the garment with the simulant to see if it is degraded. This is less dangerous, less expensive, and yet effective."

The importance of the work being done by Varnum and others at CCDC SC cannot be underestimated.

CCDC SC's surveillance work saves millions of dollars by preserving assets and CCDC SC also saves money during the actual testing by using a simulant test. The work also ensures that our warfighters are protected.

"We are making sure that the warfighter has chemical protective suits that work," said Varnum. "It feels good to know that I'm part of an organization that helps the warfighter and the nation. This particular field is interesting because we will constantly be seeing new protective materials developed as well as new instruments being developed for testing."

Nazli El Samaloty, team leader for the CCDC SC's Chemical Biological Innovative Material & Ensemble Development Team in the Soldier Protection & Survivability Directorate, considers Varnum's work to be invaluable.

"Jim's expertise and specialty is incredibly invaluable as he has enabled the Soldier Center organization to maintain a unique capability that supports a key customer; the Joint Program Executive Office for Chemical and Biological Defense, and its effort to manage stockpile of fielded CB protective ensembles," said El Samaloty. "He has mastered the inner workings of the intensive and complex test system. His knowledge gained over the years is extremely critical to CCDC SC's ability to fulfill its CB mission."

Social Sharing