CHAMBERSBURG, Pa. -- Recently, a group consisting of engineers and Non-Destructive Testing technicians from across the Joint Munitions Command enterprise completed a week-long NDT training course planned, funded, and held at Letterkenny Munitions Center.

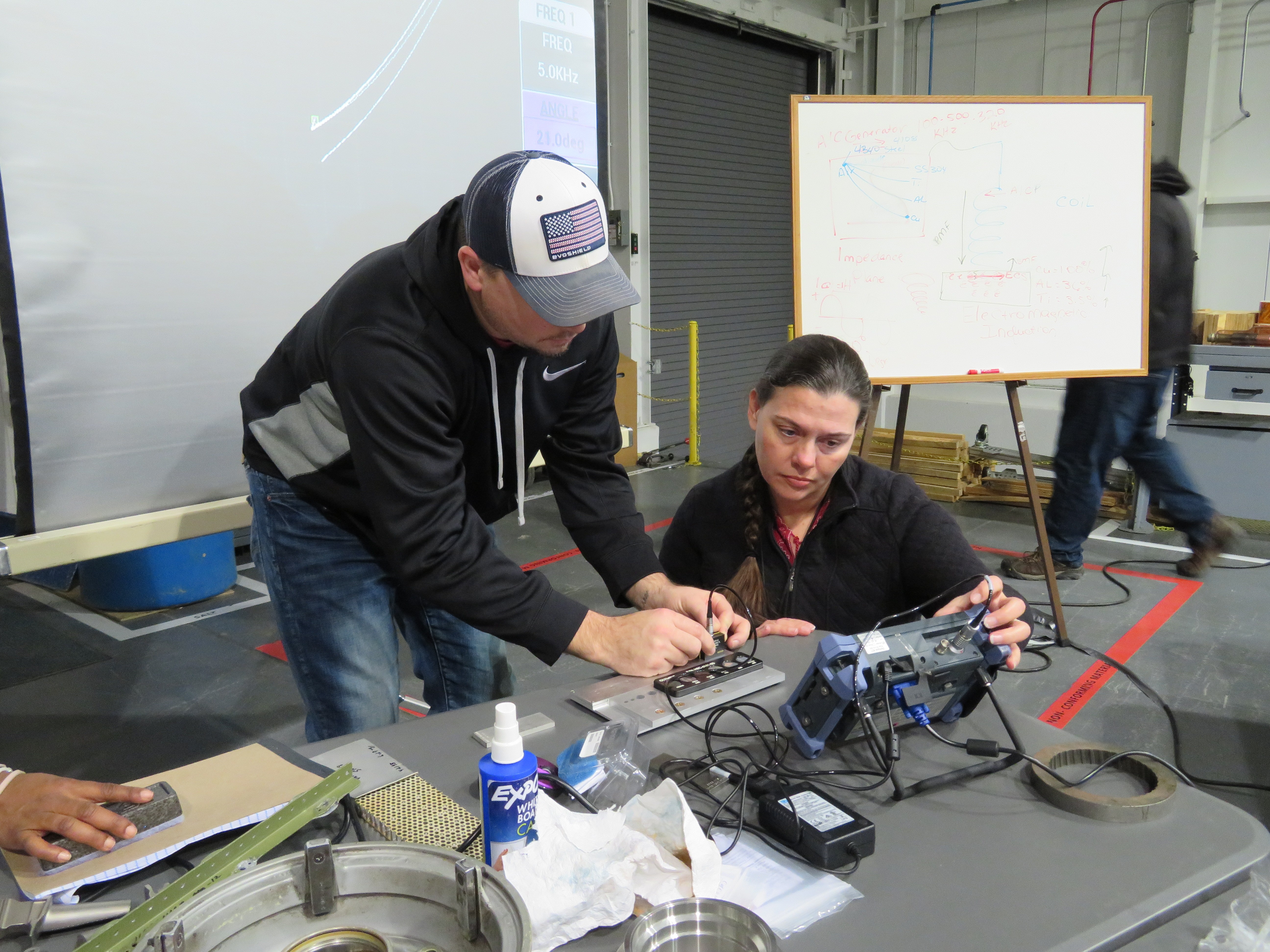

Ms. Toni Bailey, TB3 NDT Consulting LLC., Manorville, New York, presented "Introduction to Non-Destructive Testing", which included 40 hours of classroom training in conjunction with hands-on practical exercises to the group, at LEMC's NDT facility. The group included NDT technicians and members of the JMC enterprise's Integrated Product Team from JMC Headquarters, Rock Island, Illinois; LEMC; Crane Army Ammunition Activity, Crane, Indiana; and McAlester Army Ammunition Plant, McAlester, Oklahoma. Additionally, the group visited Letterkenny Army Depot in order to leverage LEAD's NDT expertise.

"NDT ensures the quality and reliability of munitions used in support of the warfighter," said Ms. Lisa Michael, LEMC's American Society for Non-Destructive Testing Certified Level III Program Manager. "TB3's training provided the group a better understanding of the different NDT applications, processes, and techniques used by NDT technicians to detect and mitigate issues with the serviceability of our munitions and to ensure safe operations."

The training provided a basic foundation and applied experience with different NDT methods performed throughout the JMC enterprise and gave the NDT Integrated Product Team an opportunity to increase practical application with these processes. The group gained hands-on experience with different NDT methods including digital and film radiography, magnetic particle, liquid penetrant, ultrasound and eddy current.

"This was really the easy part. The next important step is to now apply what we learned," said Lt. Col. Jeffrey Ignatowski. "This event was critical for our IPT to develop commensurate policy and procedures to govern our NDT operations conducted ensuring the readiness of our nation's munitions inventory."

LEMC is located on Letterkenny Army Depot and conducts regional and global distribution of munitions, provides missile maintenance, and conducts demilitarization of munitions for the U.S. Army in support of Joint Forces and international partner nations.

Social Sharing