In an article published in the September-October 2018 issue of Army Sustainment, Maj. Jamie Schwandt touts graphene as the key to the Army's ability to tap into the world's saltwater resources. While Maj. Schwandt is correct that the desalination of water using reverse osmosis (RO) is very energy intensive and expensive, the current RO capability affords the Army unmatched reach and endurance.

By sharing ideas, we, as a force, can evolve and maintain our advantage. But it is imperative to remember that it takes time to develop new technology and often even longer to replace existing systems. For now, the Army should explore a renewed effort on water treatment and emphasize being expeditionary using its current capabilities.

RELIABLE REVERSE OSMOSIS

The Army has relied on RO since the 1980s. RO provides an average salt rejection rate of 99.4 percent, and it is widely accepted as the best available option to produce high-quality potable water from brackish water and seawater. RO currently allows Army water treatment specialists to purify seawater up to 60,000 milligrams per liter for human consumption.

In his 2011 master's degree thesis, "The U.S. Military's Reliance on Bottled Water During Military Operations," then Lt. Col. James S. Moore expertly outlines many issues that prevent the Army from maximizing its organic water capabilities. He explains that commanders, planners, and Soldiers choose bottled water simply for taste and convenience. Desalinating water with either graphene or existing reverse osmosis water purification units (ROWPUs) will have little effect on the military's demand for bottled water.

When asked about graphene, a senior technical expert from the Tank Automotive Research, Development and Engineering Center (TARDEC) stated, "Most of what we have seen is modeling, theory, or an experiment with a tiny layer of graphene that has shown some water flow and salt rejection but not equivalent to current RO performance."

The facts are that the U.S. military has the ability to desalinate water, and this capability must be protected, exercised, and maintained ahead of future modernizations.

A WORLD WATER CRISIS

An affordable and efficient means to desalinate water is vital to help shape a more stable world, especially as a world water crisis becomes more imminent. About 71 percent of Earth's surface is covered by water. Unfortunately, only 2.5 percent of that is fresh water, and only 1.2 percent is easily accessible surface water.

Water is considered a renewable resource because of the water cycle. Water never sits still thanks to evaporation, condensation, precipitation, infiltration, and runoff. Like any other renewable resource, the challenge is keeping the supply in line with demand.

Every aspect of our lives is affected by water, and everything we consume is made of or produced using water. In January 2015, the World Economic Forum announced that the water crisis is the number one global risk based on impact to society (as a measure of devastation).

As world governments push for conservation and responsible use, should the U.S. military be any different? Army planners should understand the importance of transitioning from packaged water operations to bulk water operations when moving through operational phases.

CAPABILITIES AND MODERNIZATION

A vital aspect of the operational framework is resources. Water is the only commodity that can be organically sourced, produced, stored, and distributed by U.S. service members completely inside a theater.

Additionally, the Army is the executive agent for all land-based water resources. This responsibility is reevaluated every three years for need and effectiveness. The fulfillment of this responsibility does not lie solely on the Assistant Secretary of Defense for Logistics and Materiel Readiness nor on the Joint Water Resources Management Action Group. This responsibility falls on commanders, planners, and organizational leaders with water assets at every level.

MAINTENANCE

Several factors affect the readiness of our current capabilities and the funding for future modernization. The first is maintenance. Motor pool Mondays are not as effective when it comes to water assets. Honestly assessing and reporting on the readiness of water purification equipment requires what water purification specialists call "wet testing."

Water equipment has sensors, differentials, and other components that need water to be actively moving through the system to function. This requires a water source. Many units conduct static preventive maintenance checks and services on water equipment, thus reporting inaccurate maintenance statuses. Sometimes these inaccurate statuses are not exposed until a unit needs to deploy in support of a contingency or disaster relief.

In the late 1990s and early 2000s, I was a part of two units that had excellent water maintenance programs, and both were exceptional at water treatment. To be exceptional at water treatment, commanders with water assets have to respect it as not only a capability but also a combat enabler.

A key aspect of maintaining water equipment is establishing an easily accessible water source in garrison. Both of my units did this in different but equally effective ways.

One unit used 3,000-gallon "onion skin" storage bags in its motor pool, and the other had an old warehouse containing a 20,000-gallon bag for raw water. The water was sourced from fire hydrants. (Check with the garrison fire department; most departments have fittings with a check valve, which prevents backflow. The fire department will let you sign for one with a little coordination.) Establishing a water source gave both units an opportunity to test and train on equipment and report accurate maintenance statuses.

One of these units took it a step further and established a rotation by squad. Every Monday a different squad would roll out and practice setting up for normal operations and long-term shutdown. The following day was spent recovering equipment, researching parts, and completing Department of the Army Form 5988-E, Equipment Maintenance and Inspection Worksheets. This practice trained water treatment specialists to be masters of their craft.

This is in contrast to what happens with water assets in some units today. Water equipment sets stagnate in motor pools across all components while being reported as fully mission capable. This happens more frequently at lower echelons in which water treatment specialists are organized in platoons with other specialties and their training and purpose become secondary.

It is also a good idea to establish a relationship with your Tank-automotive and Armaments Command (TACOM) logistics assistance representative (LAR). The LAR is your unit's direct conduit to the TACOM Life Cycle Management Command enterprise.

The LAR's technical expertise can help your unit solve tough maintenance problems and can provide technical advice on TACOM-managed equipment. Being tied into the enterprise could help highlight the increased maintenance demand for aging systems, such as the 3,000-gallon ROWPU, and could drive future demand for modernization.

TRAINING

The next factor is training. Water treatment specialists are required to operate three different systems for water treatment based on echelon. The water they produce is intended for human consumption and meets Tri-Service Field Water Standards.

Many quartermaster specialties require Soldiers to store and distribute commodities. However, water treatment requires Soldiers to understand water reconnaissance, source selection, production, storage, and distribution, which all have associated equipment. Being such a technical specialty, water treatment requires continual training to reach and maintain proficiency.

The Quartermaster School's Petroleum and Water Department and the Training and Doctrine Command are working to develop water treatment training that will be available through the Army Virtual Learning Environment in order to increase proficiency.

At the unit level, a lack of training is often blamed on environmental constraints. This is easy to overcome and is usually just a matter of educating the installation environmental office about the treatment process.

From there, it is typically a negotiation about what chemicals are used and when. Merely allowing wastewater naturally to filter across terrain instead of letting it flow directly back into the source is the kind of concession that will allow a unit to complete its training.

Another purported barrier to training is the associated costs of chemicals and filters. A great example is fuel. Fuel is accounted for and issued using fuel keys that are assigned by Department of Defense activity address code. Water treatment chemicals and filters are no different; they need to be forecast and budgeted. They also need to be managed and protected.

For example, if the microfilters for the tactical water purification system (TWPS) are appropriately cleaned and preserved according to the technical manual's instructions, they can last 10 years. If not, their life span under certain conditions can be less than a year. When chemicals and filters are used as justification for not training, it often indicates a broader management problem.

Exercising water purification equipment during unit-level training is excellent, but planners at all levels should understand their roles in ensuring that the Army's treatment capability remains expeditionary.

The justification for contracting water for major exercises is often tied to the requirement for preventive medicine personnel to test the water. For continental U.S. exercises, it is easy to coordinate with preventive medicine personnel for raw water characterization.

Overseas exercises are a little more challenging because the Army Institute of Public Health will recommend raw water characterization ahead of the engagement. One reason for the additional testing overseas is that many partner countries lack an organization equivalent to the Environmental Protection Agency. Planners should not let this be a barrier or justification to not include water treatment capabilities in major exercises.

Additionally, even though the United States has robust water treatment and distribution networks, not all of our allies and partners have this luxury. Sharing our water treatment capabilities through partner engagements can have a huge effect on shaping operations.

CURRENT AND FUTURE RO SYSTEMS

The Army's current RO systems were the result of government-funded research that led to the fielding of ROWPUs in the 1980s. The current systems are designed at echelon to provide potable water from raw water sources globally.

As treatment technology has changed, the Army's equipment has changed as well. The original RO systems used traditional multimedia and cartridge filter pretreatment. The newer systems use microfiltration and ultrafiltration.

The next system that will increase the Army's capacity is the 3,000-gallon-per-hour TWPS. This TWPS was designed in house by TARDEC and will take advantage of technological advancements while mitigating some of the challenges of the current 1,500-gallon-per-hour TWPS.

The new system will go back to conventional pretreatment, which reduces complex electronics and the costly repercussions of not maintaining things such as the microfilters. Some additional enhancements include an energy recovery turbocharger, anodized aluminum couplings, and a manual operation capability.

Unfortunately, it is unclear when the system will be produced. According to the Product Manager Petroleum and Water Systems, the system has faced some challenges over the past couple of years mostly revolving around funding.

When a capability like water treatment loses priority and fades from focus, you have to ask why. Could a major contributor be our growing demand for bottled water?

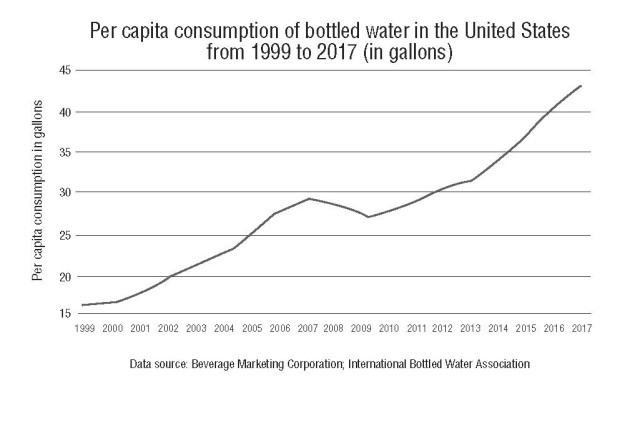

Figure 1 depicts the U.S. per capita consumption of bottled water from 1999 to 2017. Published by the World Bottled Water Association, this chart speaks volumes about how the focus on water treatment has faded over the past 20 years. The Army has allowed a growing desire for convenience to affect its water treatment capability and its ability to be expeditionary.

As TARDEC evaluates and considers new technology such as graphene, sustainers should have a renewed emphasis on being expeditionary using current capabilities. Lethality encompasses much more than fighting capability and is a demand of all warfighting functions. As sustainers, we cannot lose sight of that.

The challenge of desalinating water will continue to evolve. The truth is the Army currently has a family of systems designed by echelon that gives it unmatched reach and endurance. Modernization does not always mean new technology or materials. Sometimes it means looking back at previous capabilities and reconsidering their benefits.

--------------------

Master Sgt. Stephen J. Love is an assistant inspector general for the Headquarters, First Army. He holds an associate degree in business administration from Excelsior College and a bachelor's degree in leadership and interdisciplinary studies from Trident University. He is a graduate of the Master Leader Course and Structured Self-Development Level IV.

--------------------

This article was published in the January-March 2019 issue of Army Sustainment.

Social Sharing