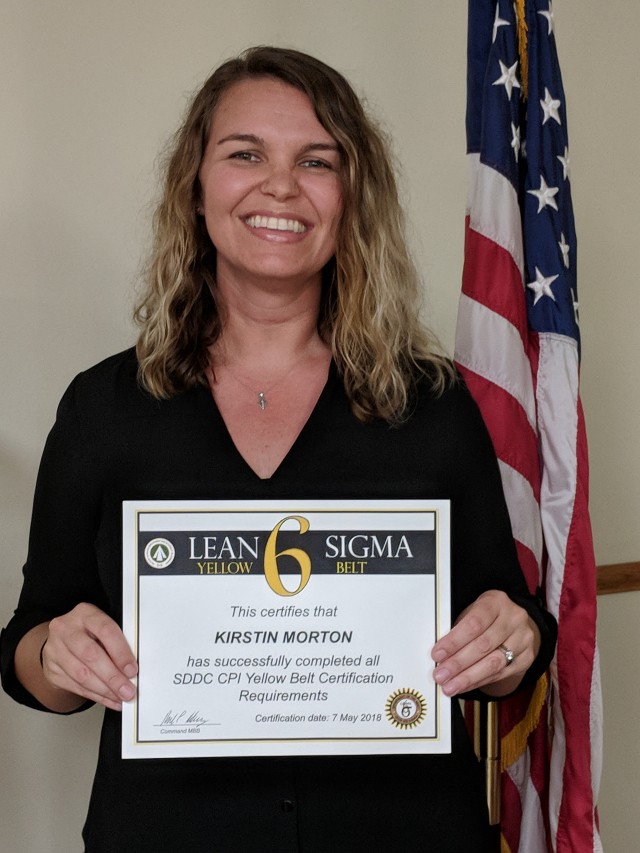

Headquarters Military Surface Deployment and Distribution Command (SDDC) Continuous Process Improvement office recently recognized Kristin Morton, former executive assistant for the 599th Transportation Brigade commander, for completing the process-improvement Yellow Belt course and subsequently saving the Army $42,335 per year in cost avoidance dollars.

"The Yellow Belt program provides basic belt concepts and tools and techniques used to mitigate quick hit issues, resulting in faster project completion and benefit realization," said Rick Rodriguez, SDDC Continuous Process Improvement Advisor.

Morton standardized and streamlined her unit's process for inputting files into the GEARS program, which is a SharePoint-based automated packet and document routing and tracking system.

"GEARS is basically a transportation highway for documents," said Rodriguez.

Morton's project required the two-hour Yellow Belt course because it was a process that could be improved quickly within her office.

"Depending on the type of project it is, it will fall into a category," said Rodriguez. "The intent is to try to give people within SDDC an opportunity to do some process improvement within their organizations--it could be in the office, for the divisions, organization or command."

The Yellow Belt course is one of several courses available to improve processes in SDDC work centers. CPI courses range from basic awareness of continuous process improvement concepts to advanced concepts and project leadership and group facilitation.

The CPI program continues to be an integral, operational-support element for the command. Since fiscal year 2009, the command has had a combined cost avoidance of over $42million with an average return on investment of 600 percent. For more information about how you can improve a process within your organization, contact Rick Rodriguez in the SDDC Continuous Process Improvement office at richard.l.rodriguez.civ@mail.mil.

Social Sharing