ABERDEEN PROVING GROUND, Md. -- A new suite of laboratory equipment lets researchers shake, rattle and roll experimental designs to discover new technology solutions for the Army of the future.

"Most equipment doesn't work well when it's being shaken really hard, like people don't work well when they're being shaken really hard," said Dr. Robert Haynes, U.S. Army Research Laboratory. "Anything we can do to reduce the amount of shaking is going to be a benefit to the Soldier and allow the Soldier to be more effective, allow the equipment to be more effective, and allow the vehicle to operate in a regime that maybe it couldn't before where it would just shake apart."

The way the electro-dynamic machine works is through a large hydraulic power unit that's pumping oil through the machine. There are 12 large cylinders that act as individual shaker units. The units provides a big force -- a punch basically to the aluminum table. Researchers can precisely control how big that punch it is.

"We set up a test in such a way that it's very controlled," he said. "Via the response on the structure and on the table it's very controlled."

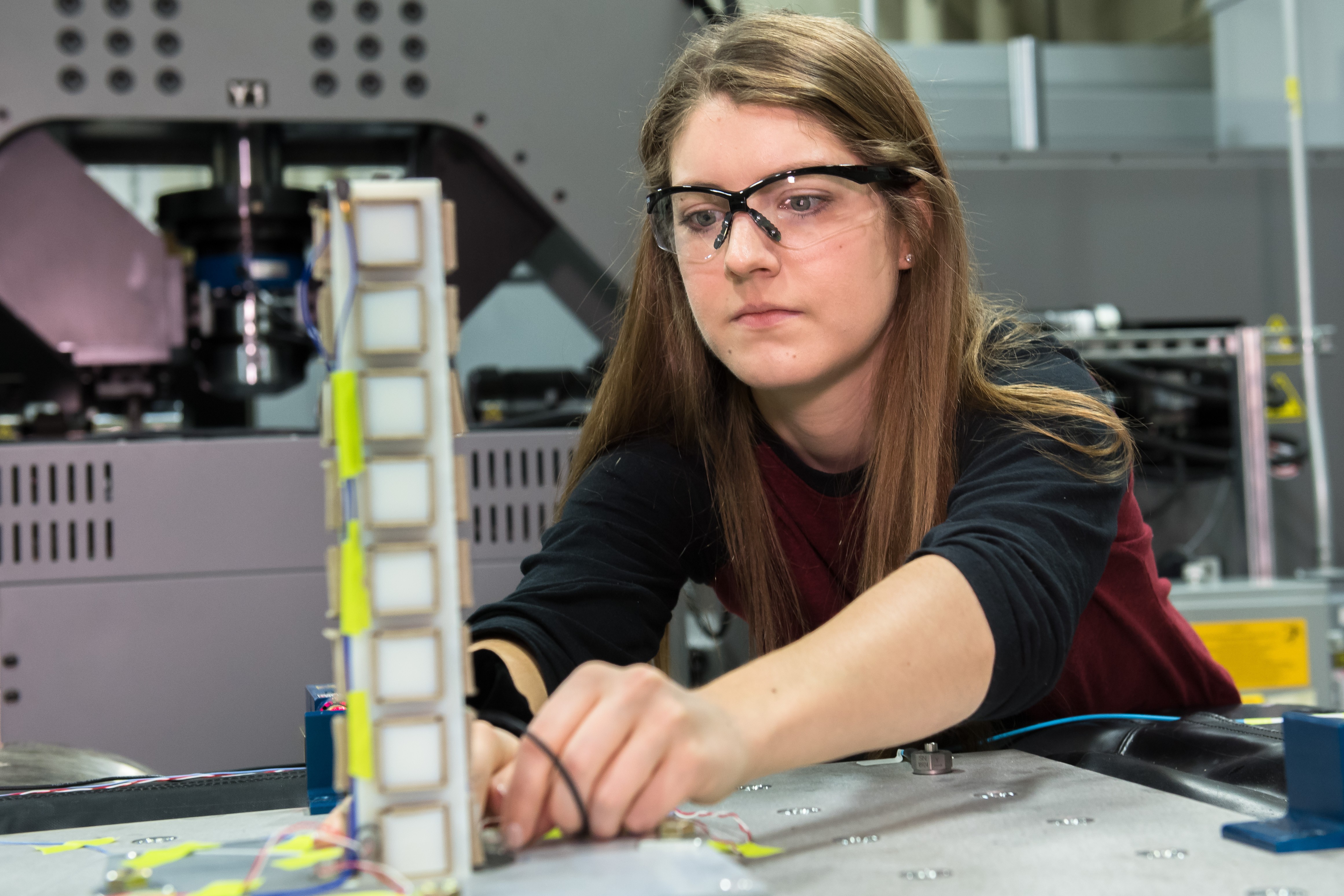

In their first set of major experiments since the equipment came online, University of Michigan doctoral candidate Brittany Essink wanted to gather experimental data on her research project.

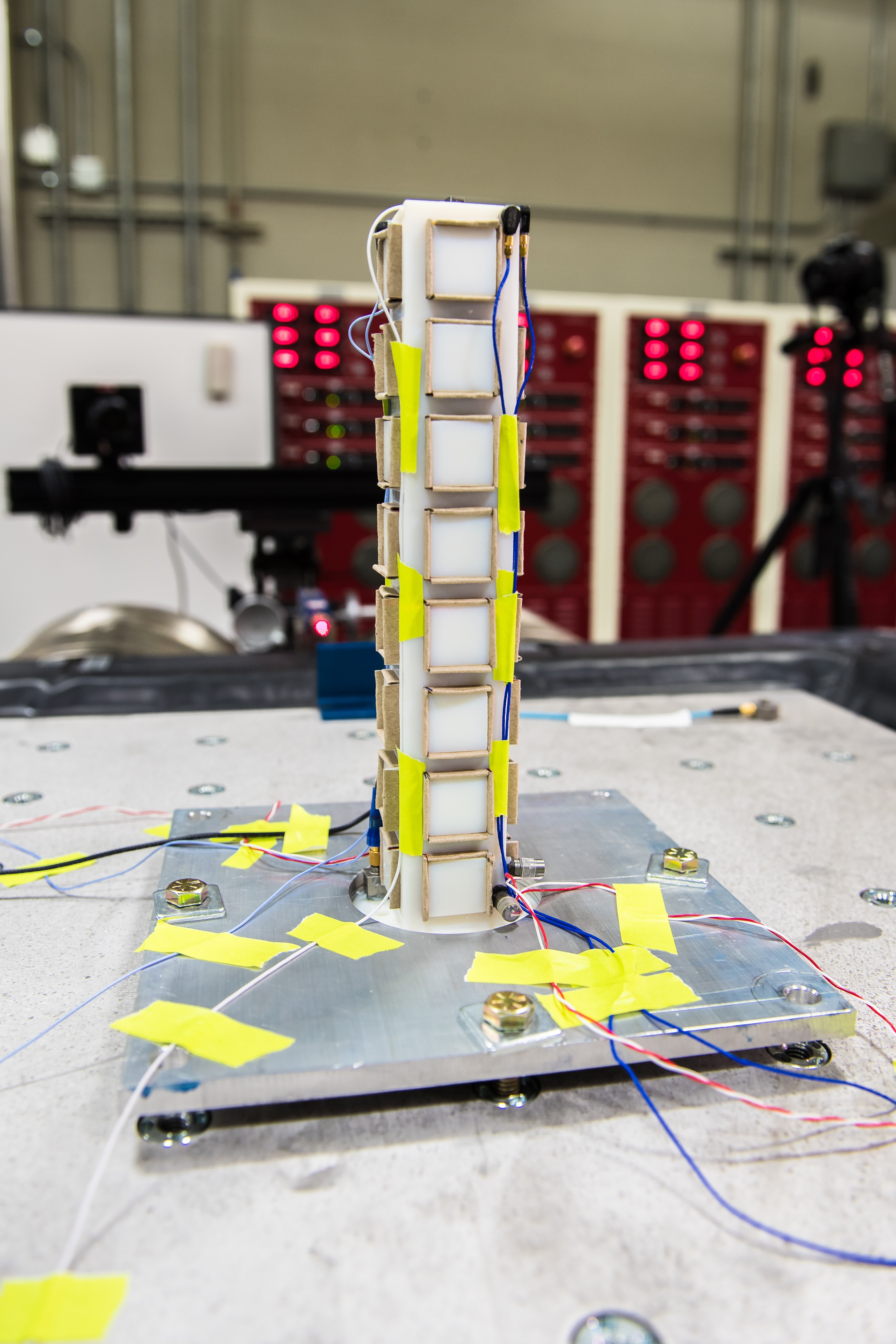

"I am studying vibrations in mechanical structures and I work on damping some of those vibrations as well as creating structures that can shift frequencies," Essink said. "I work on damping those vibrations, but I also work on shifting the frequencies in specific structures so say you have an excitation that has a specific frequency, but your structure that you're using or your equipment also has a natural frequency at the same frequency that's going to cause a lot of issues. So with these structures, and the absorbers I design, they can shift the natural frequency of structures away from that original frequency and that will help with using the equipment or whatever."

The Army Research Laboratory collaborates with many universities on research that may be off value to the future Army. In this case, the scientists said discovering new techniques to dampen vibrations could improve everything from gas turbine engine design to medical equipment.

"I've learned that on a helicopter in certain situations doctors can't use their stethoscopes because the vibration from the helicopter interferes with using the stethoscope because the natural frequencies match up," Essink said. "With this type of structure, if you were to design a stethoscope medical device that uses this kind of technology you would be able to use it on a helicopter, which could save lives in you know dire situations."

The test equipment is complicated. Its manufacturer worked closely with the team of Army researchers to install and calibrate the machinery, and then train the operators.

The multi-axial vibrations are virtually imperceptible to the human eye, but the sensitive equipment picks up on every slight movement.

Haynes said his team of researchers has many future projects on deck to maximize the beneficial data coming from the new facility.

"The real story is that this unique capability will give the laboratory the ability to do a whole series of first-of-a-kind characterizations to validate complex vibration theories that open entirely new design spaces that were unachievable before for Army mobility platforms," said Dr. Jaret Riddick, director of the lab's Vehicle Technology Directorate. "It introduces a major shift in the entire field of complex vibration."

________________________________________

The U.S. Army Research Laboratory is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing