FORT LEE, Va. -- "Installation of the Future" is among the oft-spoken terms within the walls of the Pentagon these days.

It is a fledgling project that encourages innovative thinking to meet the goal of helping installations tackle the challenges facing tomorrow's Army. Within that realm of imagination is a Star Trek-like environ where facial recognition technology allows authorized personnel to drive on post without slowing down to show identification; or post leaders carry data assistant devices that feed them critical information about operations and activities around the clock; or high-efficiency energy management systems monitor and control interior temperatures and lighting based on occupancy.

Jordan Gillis, acting Secretary of the Army -- Installations, Energy and Environment -- laid out such a vision during his visit to Fort Lee July 19. The former Army officer and advocate for installation reform said the technological benefits will strongly complement Army readiness goals and bolster the capabilities of its power projection platforms.

"What we are trying to do with Installations of the Future is to (examine how and where) we can leverage smart city technologies on installations (to achieve) quality of life, operational efficiency and base funding improvements," he said during a discussion with garrison leaders.

Later during his visit, Gillis was provided a glimpse of what the facility automation component of his vision might look like. He was briefed on the Energy Management Control System, a secure computer network-independent heating, ventilation and air conditioning setup that uses automation and sensors to individually regulate temperature, humidity and air flow within installation facilities.

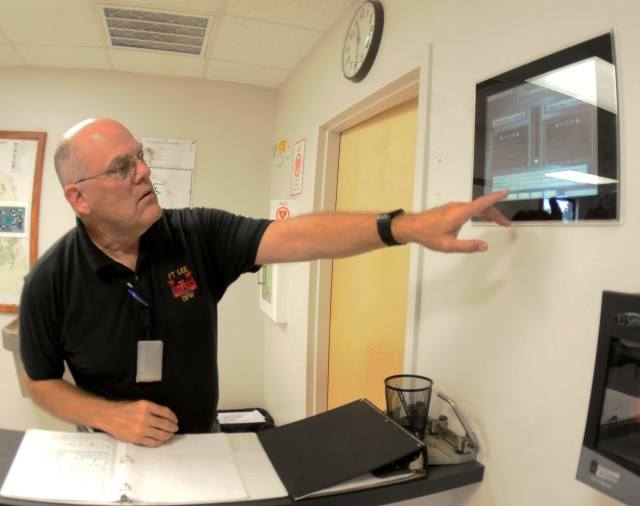

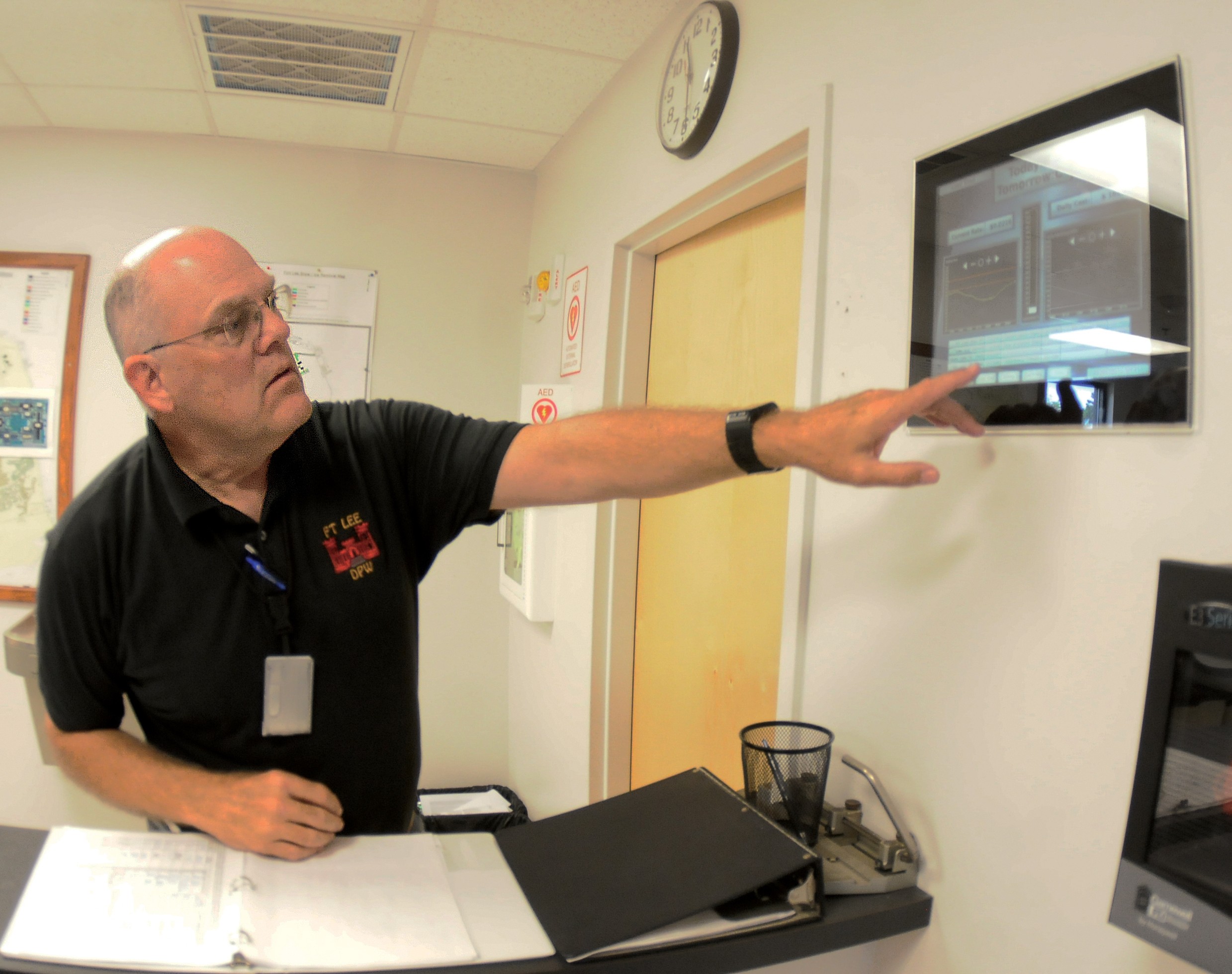

EMCS, the current version of which came online in 2008, manages 120 of the more than 400 buildings here, to include several training facilities the size of football fields. Buildings not managed under EMCS are either World War II-era structures, which would be too expensive to upgrade or are too small for the retrofit, said Richard Rericha, garrison energy manager, Directorate of Public Works. All new construction on the installation, he added, includes specifications that accommodate EMCS.

Gary Ogden, chief of the DPW Energy and Utilities Branch, has witnessed many upgrades to building control systems and contrasts each one to the practices of a few decades ago when maintenance personnel were burdened with the task of physically visiting each building in the early morning hours to ensure systems were operational prior to employees arriving to work.

"It was very, very labor-intensive," he said, also noting it was quite expensive.

Today, making daily HVAC maintenance calls to buildings is an ancient practice. "The biggest thing (EMCS) does is bring all the data to a central location," he said. "You no longer have to visit every building. We can sit in front of a computer screen, work through the graphics, and very quickly find where the problems are."

When issues are found, maintenance personnel likely know exactly what to look for and are sent to the specified facility. EMCS' ability to efficiently manage maintenance costs is where it has earned its stripes, said Ogden.

"In the area of labor for control technicians and mechanics, we've estimated a savings of about $6 million per-year because, instead of having to come in early during the day, they can start at regular time and go out and make immediate repairs as needed versus roaming between buildings to see they are running OK," he said.

Cutting energy costs is another area in which EMCS earns high marks.

"For example," said Ogden, "with the old systems, there was something called automatic reset of hot water temperatures based on outside air. When it was cold in the winter, the system would send a signal, and we would produce water at 180 degrees. Nowadays, we look at the interior building conditions, and we'll reset the hot water based on what's actually happening in the building because it could be 20 degrees outside, but if my building is at 75-80 degrees, I don't need 180-degree water to keep it at that temperature. There is an energy savings there."

"Somewhere around a million dollars" annually is Ogden's estimate of EMCS savings during initial startup. "It would be closer to $1.5 million today," added Rericha.

Additional savings have come from a load-shedding, optimal start-stop program recently installed on the system. David Foltyn, a systems integrator with Johnson Controls International -- the EMCS management company -- said the advanced programming allows the installation to better manage its pocketbook when paying for mega-wattage by reducing energy use on peak days, which is how the electric utility sets rates.

"We look at the megawatt usage on the installation, and when it gets to a certain value, we will start changing temperature set points in the spaces to save energy," he said. "We may turn equipment off just for a short period of time so we can bring our megawatt usage down. Consequently, that brings our peak megawatt usage down for the year, which we pay a fee to use so much power, and it brings our daily costs down as well."

The load-shedding program is capable of producing $200,000 in yearly savings, said Rericha, and that figure is likely to grow with the ongoing EMCS version upgrade that includes an enhanced operating system and new servers.

Eyeing potential EMCS functions in the future, the DPW team envisions utility add-ons such as lighting and other controls geared toward saving energy and reducing cost.

"The trend we're going to be looking at is we want to be able to sense where people are in the building using motion detectors, and have that tied into the HVAC system," he said. "Now, we can control lighting and HVAC with simple occupancy sensors. That's probably the way things are going to go."

In terms of upkeep, a fulltime systems integrator is critical, said Ogden, noting some installations are without one.

"There's a real loss there because if you have somebody watching the system, they can work with your maintenance department and get quicker response times when people are calling in problems," he said.

Additionally, EMCS must be continuously updated, said Rericha.

"Just like any other computer program, it needs to be maintained," he said. "I you don't install the updates, you can lose functionality -- that ability to make things easier."

All told, EMCS is efficient and cost effective. While it is not quite the innovation of facial recognition, which could be years away, it is a technology that is making a difference today and quite possibly the closest link to the Installation of the Future to date.

Social Sharing