KAISERSLAUTERN, Germany -- The Army Oil Analysis Program laboratory at the Kaiserslautern Army Depot recently received the recertification for the International Organization for Standardization 9001:2015.

The AOAP laboratory is the Army's only ISO-certified oil analysis lab. It is part of the Department of Defense-wide effort to predict equipment component failures and lubricant conditions by testing oil samples from different types of equipment such as vehicles, generators, and aircraft.

The laboratory received its first ISO certification in 2008.

ISO establishes an integrated control circuit for quality management systems. The standard validates that the AOAP's quality management system is compliant with a best-practice standard.

"If you are ISO certified, you provide the customer with the guarantee that the services you provide are of a high standard," said Heidi Bodeit, director, AOAP.

"The certificate is issued by a third party. It helps the organization to be more efficient and improve customer satisfaction," added Akwasi Edusei, an AOAP administrative assistant, and a quality management representative.

The AOAP Laboratory Europe services commanders in Europe, Africa, and Southwest Asia. It accepts oil samples from aircraft and ground-based vehicles that technicians analyze looking for imperfections and inconsistencies.

Water, metallic elements, and sediment in the oil may lead to a fault or catastrophic failure of equipment.

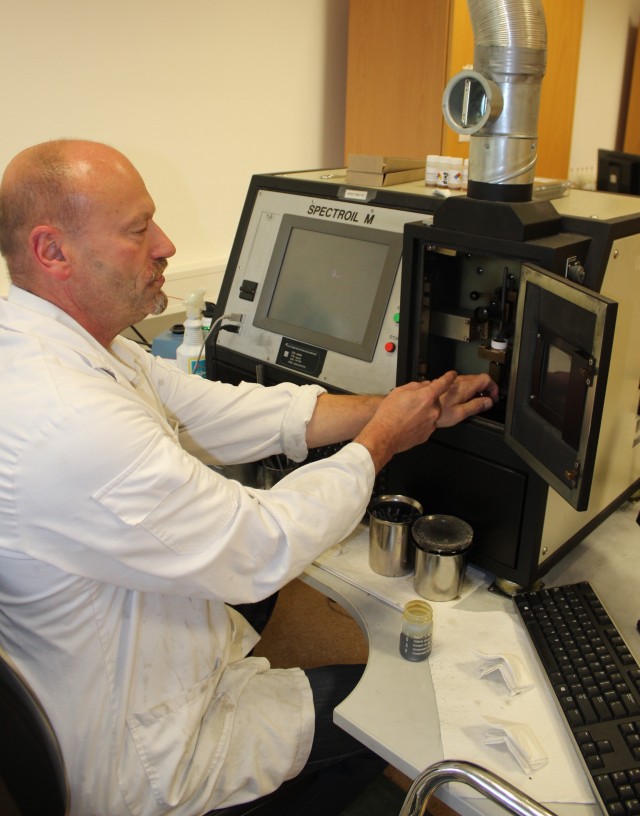

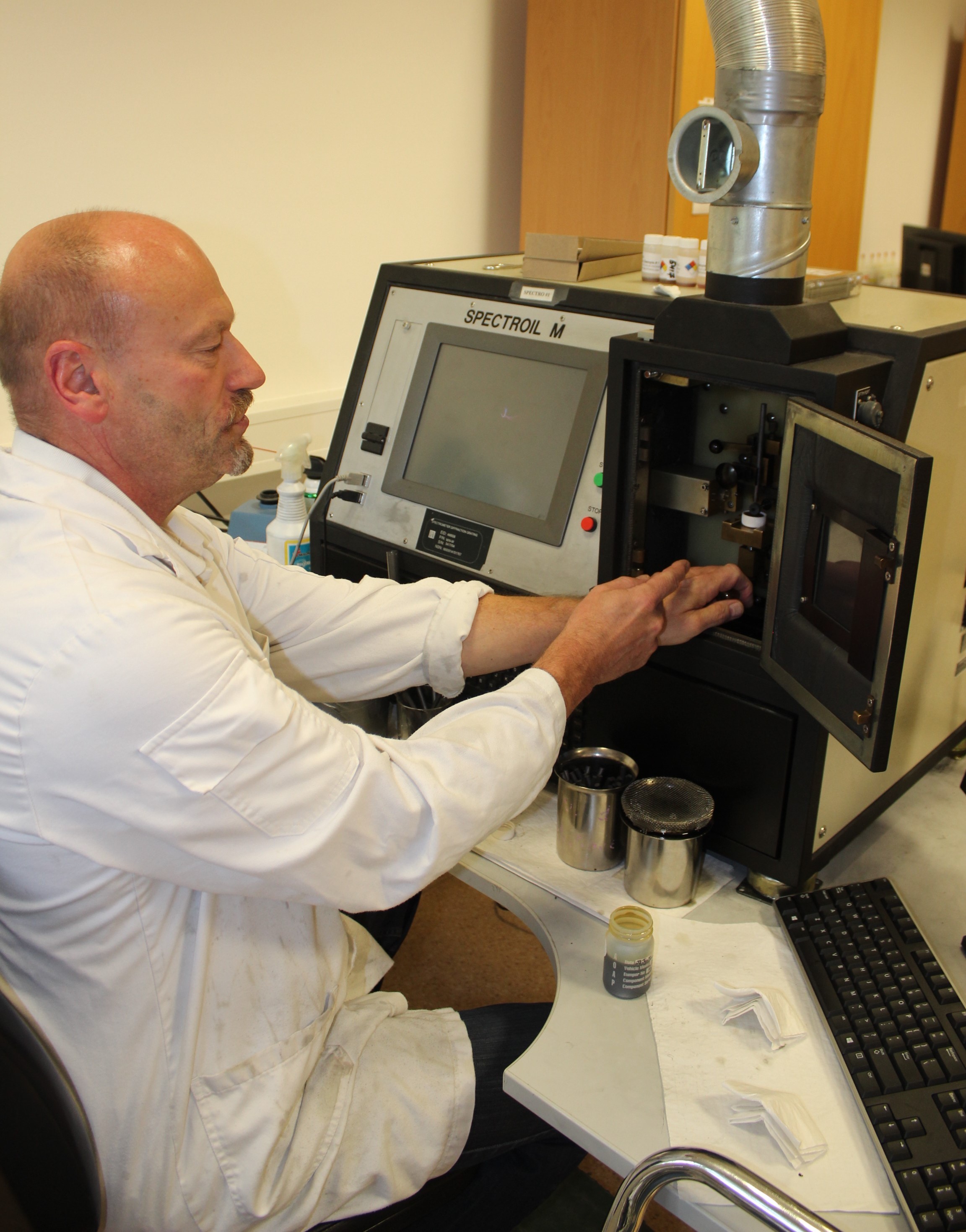

AOAP lab professionals inspect oil samples manually by microscope and electronically tests them for impurities. This service increases combat readiness and safety, reduces component failure and life-cycle sustainment costs, helps protect the environment, and provides maintenance recommendations.

"We examine the oil's viscosity or thickness first. This process helps to tell if the oil is still 'healthy' for use or needs replacing. Time may indicate a vehicle needs an oil change, but the oil may still be good. Getting rid of oil unnecessarily costs the American taxpayer money," Bodeit explained.

"We provide a preventive maintenance tool. It is able to tell you what is likely to be going wrong with your equipment in the near future based on the elements we may find in the oil," she said.

"We are an environmental tool because often we are able to extend the intervals of oil changes. If the oil viscosity is still good, why change the oil? This avoids purchases of new oil, new filters, disposal oil, cost-saving factor," Bodeit said.

Even though only certain aviation and ground vehicles are required to enroll in AOAP, Bodeit thinks more vehicles could benefit from it. "I encourage commanders to enroll other equipment, as well," she said.

To contact the AOAP Laboratory, call DSN 314-483-79782 or CIV 0631-411-7982.

Social Sharing