REDSTONE ARSENAL, Ala. -- In the world of Army value engineering, projects have a big impact on materiel readiness.

Reliability, quality, safety, cost savings, performance, lowering weight, recycling, speed of delivery - all are factors considered when engineers work to redesign more value into equipment used by Soldiers.

And, every year, as redesigns are completed and new equipment is introduced in the field, the personnel behind the projects are recognized through the Department of Defense Value Engineering Awards Program, taxpayer money is saved and program managers realize better equipment performance.

But, in the end, it's the Soldier who is the real beneficiary of the program.

"Ninety-nine percent of what we are doing comes with a financial benefit - either a cost savings or a cost avoidance," said Todd Hutto, an Army Materiel Command employee who serves as the Army's value engineering manager.

"Even though saving money is at the core of what we are doing, support to the Soldier is always paramount. Improving reliability and functionality goes hand-in-hand with reducing costs."

The financial benefits of the fiscal 2017 Army Value Engineering Program increased 14 percent over fiscal year 2016, Hutto said. The fiscal 2017 projects resulted in $533 million in savings and cost avoidance, an increase of $73 million over fiscal year 2016's cost savings of $460 million.

"We had a very aggressive program and found ways to make a difference with the Army's Value Engineering Program," Hutto said.

This year, DOD Value Engineering Awards were presented to seven Army organizations or civilians, with six of those affiliated with Army Materiel Command. The winners in specific categories are:

• Project - Project Manager, Combat Ammunition Systems, Picatinny Arsenal. N.J./Rock Island Arsenal, Ill.

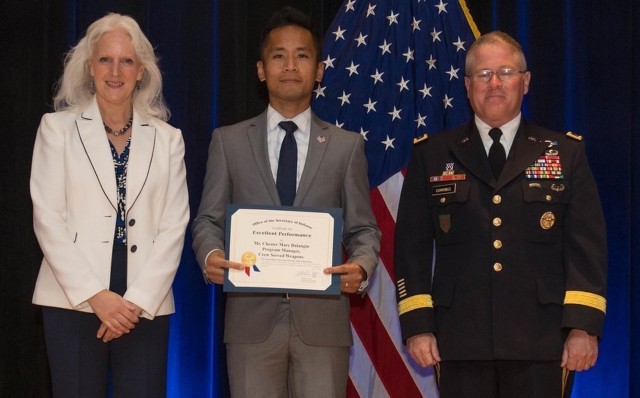

• Individual - Chester Marc Dalangin, Product Director, Precision Weapon Optics, Fire Control and Accessories, Product Manager Crew Served Weapons, Program Executive Office for Soldier, Picatinny Arsenal

• Team - Watervliet Arsenal, New York

• Organization - Aviation and Missile Command, Redstone Arsenal

• Special - Apache Production and Fielding Value Engineering Team, Apache Project Manager's Office, Redstone Arsenal

• Special - Project Manager, Armored Fighting Vehicles, Detroit Arsenal, Michigan

• Special - John Hedderich, Director, Armament, Research, Development and Engineering Center, Picatinny Arsenal

In addition, both the Navy and Air Force received seven Value Engineering Awards, the Missile Defense Agency received six, the Defense Logistics Agency received five and the Defense Threat Reduction Agency received one.

Every government agency by law is required to have a value engineering program, Hutto said, adding "the Department of Defense has tasked every service to participate in Value Engineering."

The first Value Engineering office stood up in the 1960s, soon after Army Materiel Command was established. Historically, four of the command's major subordinate commands - Aviation and Missile Command, Communications-Electronics Command, Joint Munitions Command, and Tank-automotive and Armaments Command - have been strong contenders in the Value Engineering Awards program. This year, AMCOM won in the organization category for the third year in a row.

"This is unprecedented," said Tom Reynolds, who manages AMCOM's Value Engineering program. "Winning in the organization category two times in a row is rare. Winning three times is a very big deal for us. AMCOM has had tremendous results with value engineering. We have a lot of engineers committed to this program and we have issues raised that are good for value engineering projects."

While cost savings are a priority, not all value engineering projects lead to cost savings.

"Our mission is to improve function and value for Soldiers and our program manager customers," Reynolds said. "But, they don't always save money. Sometimes it costs more to get more capability. Or, we may save money but it might not be auditable or it may involve a classified program."

Value engineering projects begin with two basic questions: Why does it cost so much? Is there something we can do to realize better cost savings?

"It's all about understanding the value in a product, process or service, improving the functionality, and reducing cost," Hutto said. "It's about challenging the cost of everything. You might only save a small amount per item, but when you have significant quantity of scale, you can get some pretty exciting cost savings."

Reynolds works with engineers throughout AMCOM, providing value engineering training opportunities, brainstorming sessions and team meetings.

"I don't think there is any other organization out there that has the depth and breadth of results like we do at AMCOM," Reynolds said. "That doesn't mean we can't get better. But, we have many program managers and engineers with institutional value engineering knowledge that they share, and other engineers can seize upon, and we get results year after year.

"AMCOM will be there every year with value engineering because of those engineers and because of the support we receive from command leadership."

AMCOM, like many of Army Materiel Command major subordinate commands, is heavy on commodities, making it easier to pinpoint equipment that needs Value Engineering improvements.

"TACOM, for example, has the most complex mission of all major subordinate commands in terms of the number of tanks, track vehicles, wheeled vehicles, boats, small arms, pistols, rifles other systems, and all the other bits and pieces it manages. So they have a great opportunity of being able to find Value Engineering projects that can create substantial cost savings," Hutto said.

"In aviation, weight is super critical. There are always opportunities to try alternative materials for weight reduction, and more strength and reliability."

Hutto said that, even in commands with fewer commodities, there are value engineering projects to be tapped into.

"We are working with dynamic systems. There are changing environments, changing threats and changing societal values that can lead to the need for improvements," Hutto said.

Social Sharing