ROCK ISLAND ARSENAL, ILL.-- Joint Munitions Command's approach to managing the ammunition business is changing to reflect the Army's new emphasis on Sustainable Readiness.

"We are the command that gets the ammunition there," said Rhonda VanDeCasteele, Deputy to the Commander, JMC. "As an integral part of the munitions enterprise, we force-project ammunition whenever and wherever it is needed."

U.S. Army Materiel Command, JMC's higher headquarters, has developed a strategy to link the Organic Industrial Base output to the Sustainable Readiness Model, which is the Army's current readiness model.

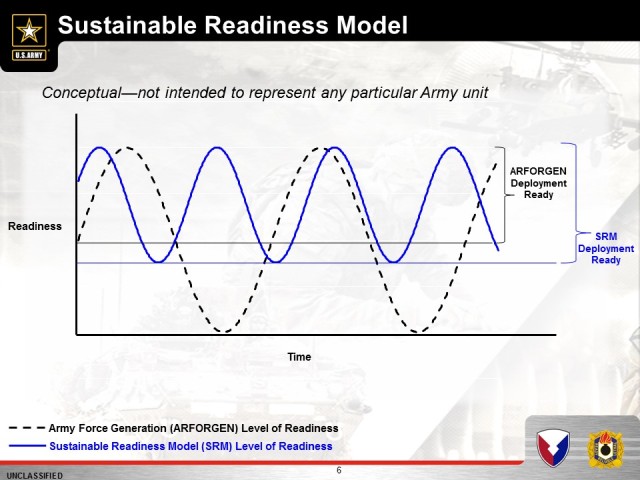

Previously, when the Army operated under the Army Force Generation (ARFORGEN) model, the focus was to create readiness for deployed and soon-to-be-deployed units. Units not deployed, or in the early stages of getting ready to deploy, were often depleted of equipment in order to supply the units downrange.

With SRM, all units will be supplied at some level of deployable readiness. This compels both JMC and the operational units to strive to more accurately forecast future ammunition needs.

"We understand the near-term requirements but are working on better forecasting long-term ammunition requirements," said JoEtta Fisher, Deputy, JMC's Munitions and Logistics Readiness Center.

Another change that SRM brings is the need to link ammunition logistics requirements to specific Army units. Under SRM, JMC's budget requirements will be tied directly to specific unit readiness needs. With a better understanding of JMC's logistics requirements and how those funds support specific units, JMC can more clearly communicate the impact on individual Army units if the Command does not receive its full budget request.

"Sustainable Readiness is unit and brigade combat team-centric and driven by the Sustainable Readiness Program (SRP) to enable combat power. The end state is that Army formations are ready to deploy immediately and are postured to meet combatant commanders' requirements," said Gen. Gustave F. Perna, Commanding General of Army Materiel Command, in the May-June 2017 issue of Army Sustainment Magazine.

The SRM will also allow the plants and arsenals that form the munitions OIB a greater degree of consistency and stability in their workload demands. Seventy percent of JMC's items are produced in the commercial sector, which struggles to deal with large variations in demand, such as those common under the ARFORGEN readiness model.

"As use of commercial sector suppliers ebbs and flows, we have concerns about which suppliers will be available to meet our future needs. The SRM will give suppliers more predictability of future demand and help enable their longer-term business planning," said Brig. Gen. Heidi J. Hoyle, JMC Commanding General.

The SRM will also help reduce the fluctuations in the size of the OIB workforce needed to meet demand. Because the demand will be more steady and predictable, the concerns associated with seasonal or temporary work may be alleviated.

One key purpose of the SRM is to generate consistent readiness for the Army. JMC is moving toward SRM to better support the Warfighter.

"Under the SRM, all units are ready for a no-notice deployment," said Brig. Gen. Douglas M. McBride, Jr., Commanding General of the 13th Sustainment Command (Expeditionary), who visited JMC in January and discussed application of SRM with JMC leadership.

Army commands will each tackle SRM slightly differently, based on individual mission sets. JMC will work the SRM through three areas of focus:

- Focus Area 1: Requirements Synchronization and Forecasting: Develop ammunition distribution requirements to meet SRM-driven unit and institutional training needs and planned operations, and factor these requirements into JMC's operational budget request.

- Focus Area 2: Depot Operations and Supply Chain: Increase logistics and production capacity and throughput; reduce cycle times; reduce carryover; and build greater alignment and coordination between the installations and JMC Headquarters.

- Focus Area 3: Production/Replenishment: Synchronize shipments and receipts, tie production to readiness, sustain critical capabilities, manage contractor performance, and resolve key execution issues.

"To ensure a successful transition to the SRM, we are dedicating personnel to coordinate the work being done in the three focus areas and facilitate necessary changes at JMC Headquarters and the installations. JMC will continue to receipt, store, and issue munitions to the Joint Warfighter. We will meet all requirements, from basic training to global battlefield dominance," said VanDeCasteele.

In order to more fully educate the workforce on its application to JMC's mission, Headquarters JMC will be hosting Lunch and Learns on SRM in upcoming weeks.

Social Sharing