ABERDEEN PROVING GROUND, Md. (February 2, 2018) -- The good news for today's Soldiers is that they are all now equipped with modern military-grade electronic devices that enhance their mission operations.

The bad news is that each device requires batteries, and multiple spares, which substantially increases the Soldiers' load.

Research and development, or R&D, teams across the Department of Defense, industry and academia are teaming to produce the battery chemistry required to modernize power solutions, with the U.S. Army Materiel Command's Communications-Electronics Research, Development and Engineering Center, or CERDEC, at the forefront of these innovations.

"Advancing power solutions for Soldiers is an incredibly challenging undertaking," said Beth Ferry, division chief for CERDEC CP&ID's power division. "As the Army modernizes, it is critical that we recognize and acknowledge core government technical expertise."

CERDEC's technologies aim to meet the Army's requirement to ensure systems run for 72 hours without resupply or battery change out, which is especially critical for the growing number of small, early/forcible entry missions required for an expeditionary force.

"The Army's next generation Soldier power solutions must be smaller, lighter, possess higher energy and operate for longer periods of time than their predecessors," said Mike Brundage, chief for the CERDEC Command, Power and Integration's, or CP&ID, Tactical Power branch. "Above all, they must be safe to operate under fluid operational and environmental conditions, and be cost effective to use."

CERDEC's power experts act as the intermediary between the early innovators up to the Soldiers who eventually test the products it matures. To shepherd these new power solutions from the scientist's mind to the Soldier's hand requires domain expertise and close partnerships among multiple stakeholders.

Initial power solution concepts may be conceived at the Army's Research Lab, or ARL, Defense Advanced Research Projects Agency, or DARPA, or from within academia. CERDEC scientists and engineers draw upon their years of experience to assess these concepts for their potential ability to satisfy Army power requirements.

"If we see promise in an idea or concept, and feel that it will help satisfy Soldier power requirements, we will mature it until we have a prototype," said Terrill Atwater, CERDEC CP&ID research chemical engineer.

If the prototype produces even more confidence in the technology's potential, CERDEC often publishes a Request for Information to allow interested companies to propose how they could help continue to advance the technologies, Brundage said.

"Because we work in an R&D organization, it is not our job to manufacture anything," Brundage said. "Our goal is to transition the technology to the Programs of Record. We develop the specifications, and we can also provide them with the industrial-base partners that we have been nurturing along the way."

CERDEC's thumbprint can be found on multiple battery chemistry inventions over the past 30 years, which often began as patents and advanced to fully operational capabilities in both the military and commercial sectors.

"We developed the original cold temperature electrolytes for all batteries now found in laptops and cellphones," said Atwater. "More recently we developed cathode material that addresses a battery's state of charge, which is the display showing the remaining battery life."

Based on their previous experiences with inconstant state of charge technologies, troops would often have to guess how much power was remaining in their batteries. Soldiers would often discard good batteries for fear of losing power, Atwater said.

"We patented this inexpensive state of charge technology, and provided it to battery manufactures to license it." Atwater said. "Our business model not only allows industry to perform contract work in the Army's power space, they can also license our technologies for their specific applications. In this instance, these manufactures now produce every battery the Army buys."

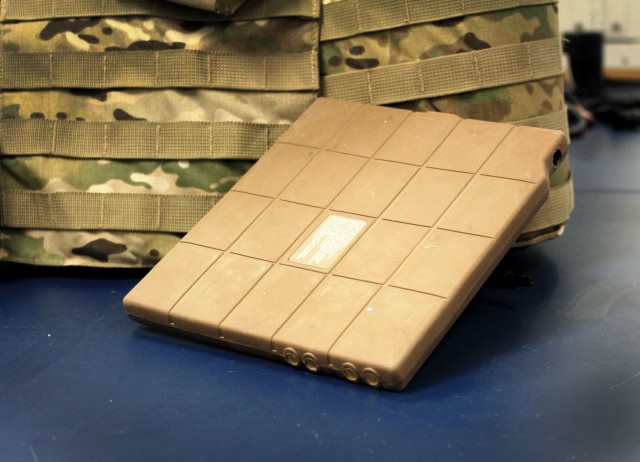

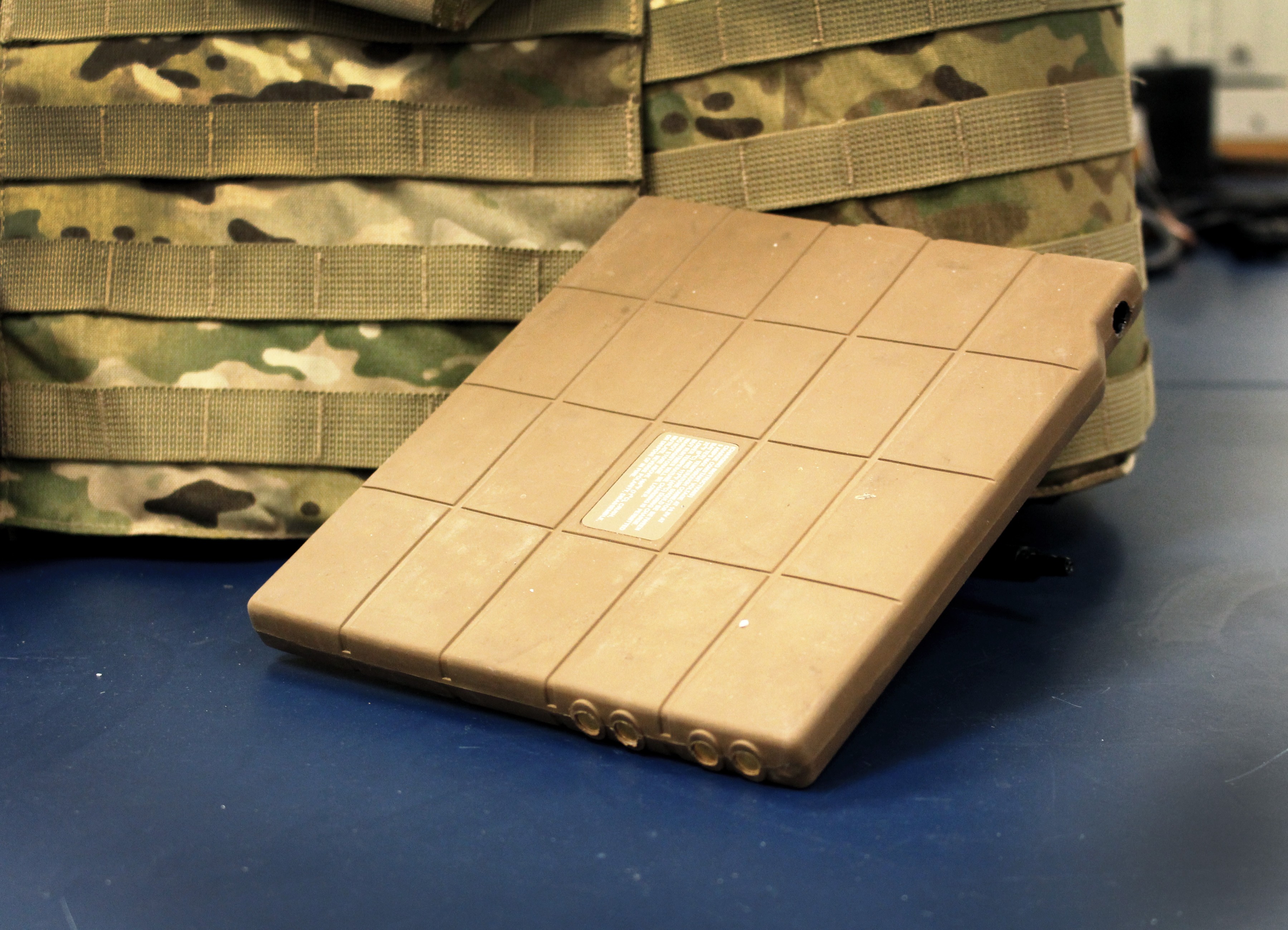

CERDEC continues to produce battery chemistries that strive to meet the power demand of dismounted soldiers such as the rechargeable Conformal Wearable Battery, or CWB, a light, safe, wearable, flexible battery that is integrated into Project Manager Soldier Warrior's Nett Warrior system. At 2.6 pounds, the CWB is safer than other tactical batteries, addresses the battery weight dilemma, and holds a longer charge than standard military batteries. The CWB is the baseline for a more mature product that will incorporate more advanced lithium-ion chemistry to meet the 72-hour mission requirement.

One of the greatest challenges to developing these innovative power sources can be the unyielding time it takes to produce new battery technology. Not only do engineers require advanced electrochemistry experience, they must incorporate stringent safety requirements too.

"The reality is in the 35 years I have worked for CERDEC it takes about a decade for a new power source technology to go from promise in the lab to fielding," Brundage said.

Over the past ten years, CERDEC continues to advance lithium-ion chemistry and is producing a new hybrid lithium ion technology that will provide higher power density and higher energy to advance not just the conformal battery, but will be used to power other future Army technologies, Brundage said.

"None of this happens if we don't put safety first," Brundage said. "Each time we finally package the materials into a cell and place them into their intended unit, such as a steel can, we have an energy equivalent of a half a stick of dynamite. Science, or thermodynamics, tells us the cells should not reside in that can for longer than a micro second without exploding."

The Army of 2030 and beyond will demand an even greater length of time troops will be required to operate without power resupply. By collaborating with experts across the power spectrum, CERDEC uses its expertise to reduce these advanced concepts to practice, Brundage said.

"The overarching goal of whatever we do is to reduce the burdens on Soldiers in terms of weight and volume," Ferry said. "Our power solutions must enable a modern, expeditionary force no matter the demands placed on our troops."

Related Links:

U.S. Army Communications-Electronics Command

U.S. Army Research, Development and Engineering Command

U.S. Army Communications-Electronics Research, Development and Engineering Center

Social Sharing