NATICK, Mass. -- Two research, development and engineering centers have come together to collaborate on making unique parachutes from high-strength para-aramid materials, which are sometimes used in ballistic vests and body armor.

The Natick Soldier Research, Development and Engineering Center, or NSRDEC, is working with the Armament Research, Development and Engineering Center, or ARDEC, on special purpose parachutes for use with artillery projectiles. Both centers are part of the Research Development and Engineering Command.

Richard Benney, director of NSRDEC's Aerial Delivery Directorate, praised the collaborative work on the para-aramid versions of the tri-lobe and cross parachutes.

"NSRDEC's Aerial Delivery Directorate and ARDEC continue to work closely together in many areas, and the collaborative work on the tri-lobe and cross parachute projects is a great recent example of our close partnership," said Benney.

"Collaborations on munition parachute designs, future assured resupply joint planning, working closely on both past and expected future Joint Technology Capability Demonstrations, or JCTDs, with other services, along with the continued munitions certification efforts with ARDEC PM partners are just a few examples of activities both RDECs work on jointly to support the Warfighter."

"I think collaboration is beyond important," said Scott Martin, team leader of the Aerial Delivery Design and Fabrication Team at NSRDEC. "In the Parachute Prototype Shop, collaboration is the only way we can produce the absolute best design for our parachutes. Being able to interact with engineers, either here at Natick or with outside agencies, makes all the difference."

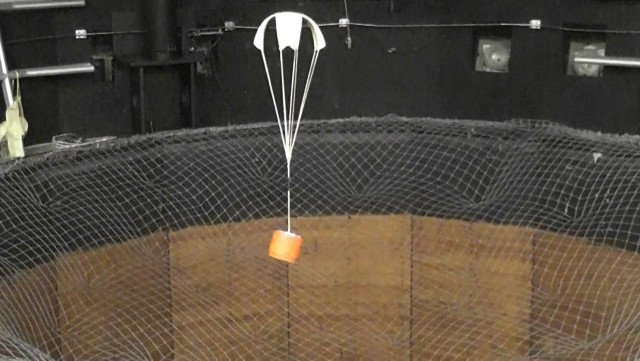

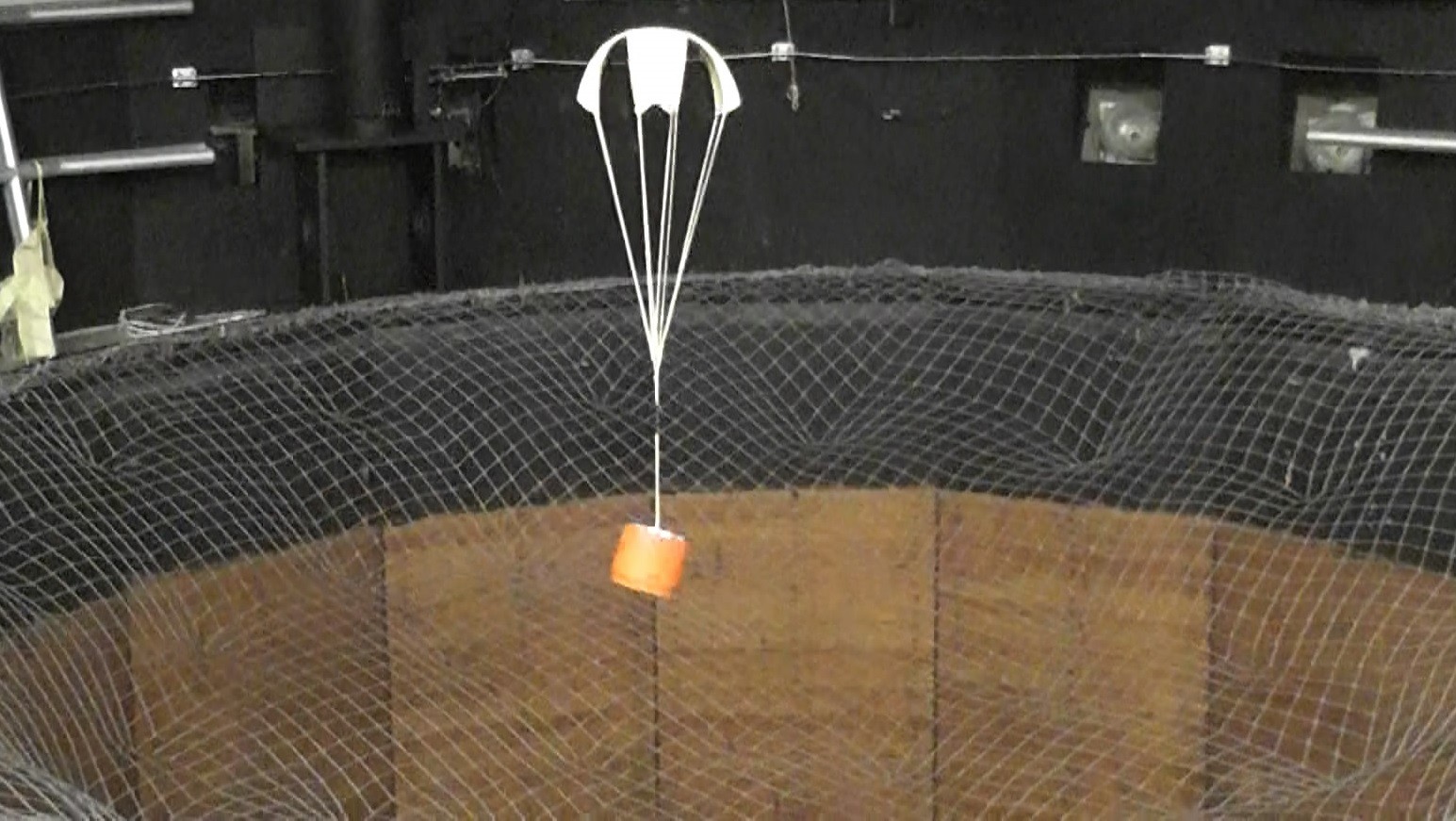

Walt Koenig, an aerospace engineer in the Aeroballistics Division at ARDEC, is working with NSRDEC on a particular cross parachute design. This version of the cross parachute is used to stabilize an artillery projectile sub munition and optimize its performance.

"My role in this program is to develop a system to orient and stabilize a munition contained in a 155mm projectile," said Koenig. "NSRDEC has provided invaluable assistance in reaching that goal."

ARDEC engineers are working with NSRDEC's Parachute Prototype Shop on several next generation munition programs requiring decelerators. Koenig explained that one of the programs "uses a small cross chute to orient and stabilize a munition with a high reliability fuze."

"Working with the prototype shop has proven to be a cost-effective way to get small quantities of high- quality parachutes made for testing," said Koenig. "They do a great job on the chutes and are very easy to work with."

"We are fortunate to have highly-skilled fabricators and the right machinery to build parachutes like this," said Martin. "We also benefit from varied backgrounds. Many of our fabricators are prior service Army parachute riggers while others come from the commercial skydiving community. That variety of experience is a big strength for our team."

Vebiana Chavarria is an equipment specialist on NSRDEC's Aerial Delivery Design and Fabrication Team. She performed fabrication work on the cross parachute and on a part called the De-Spin Fin for the tri-lobe system.

"I think it is important to go the extra mile for the customers," said Chavarria. "It shows how much we care about the customer and the Soldier getting what they need for success. It doesn't matter to me where someone works; I enjoy learning and working with customers from all backgrounds and locations. The more I learn and understand the product, the better for the Soldier because I'm able to build a better product."

In addition to the para-aramid version of the cross parachute, NSRDEC and ARDEC are working on a tri-lobe design parachute. This type of parachute will likely be used at a test facility, such as Yuma Proving Ground, to collect various data.

Travis Heithoff is a mechanical engineer in ARDEC's Engineering Analysis and Evaluation Division working with NSRDEC on the tri-lobe project. He is working to develop a design for a reliable test asset for recovering projectile components.

Heithoff explained, "for the past number of years, ARDEC has been endeavoring to reconstitute a capability to soft-recover components from a gun-launched projectile for engineering tests."

"These soft-recovery systems allow ARDEC engineers to recover gun-fired hardware, assess design performance and make improvements, ultimately shortening the time needed to get systems into the field," said Heithoff.

"The tri-lobe project is the next phase of this effort, allowing for the safe recovery of a precision fuze fired vertically on the nose of a 155mm artillery projectile. Throughout this stage of the effort, the prototype shop has helped improve the design and identify the materials needed to allow these parachutes to survive our unique and harsh environment."

Heithoff emphasized the importance of ARDEC and NSRDEC working together.

"The Parachute Prototype Shop at NSRDEC has been an instrumental partner in this effort," said Heithoff. "NSRDEC has provided high-quality parachutes at a reasonable price, quick turn-around, and they have been exceptionally valuable regarding feedback throughout the process to help improve the design and performance."

"I believe it is extremely important that we collaborate with other organizations," said Chavarria. "Everyone has a different set of knowledge and skills which in the end helps the people we are all here to help, the Soldiers. It should never be a competition between the organizations. We should automatically want to work together to make the best product possible."

"What I like most about being part of the Aerial Delivery Directorate is that we are not that far removed from the Soldier," said Martin. "Often what we build will actually end up in the hands of a deployed soldier. Even less visible projects like the cross and tri-lobe parachutes make a difference by improving the performance of artillery rounds."

"It feels good knowing that I'm helping improve the equipment used by the Soldier," said Chavarria. "They put their lives on the line for our freedom, so the least I can do is give everything I have to each project."

---

The U.S. Army Natick Soldier Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to provide innovative research, development and engineering to produce capabilities for decisive overmatch to the Army against the complexities of the current and future operating environments in support of the Joint Warfighter and the Nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing